Oxidant composition and method for treating hydrazine hydrate in industrial sewage

A technology for industrial sewage and composition, applied in the field of chemistry, can solve the problems of low efficiency, high production energy consumption, long processing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

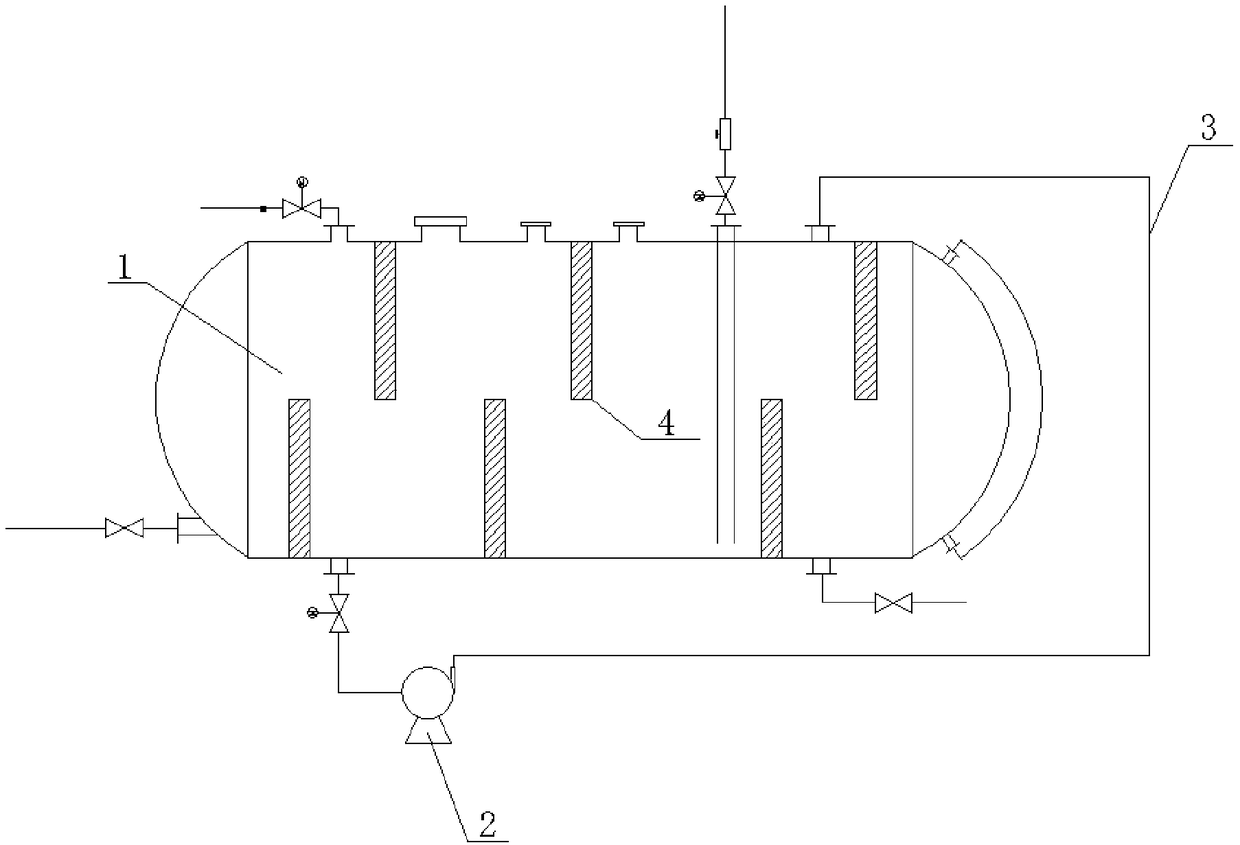

Image

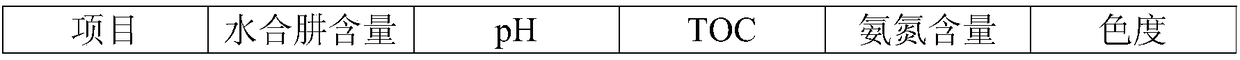

Examples

preparation example 1

[0067] Preparation example 1, preparation of oxidizing agent composition

[0068] 1), 3Kg 2,2'-bipyridine and an appropriate amount of FeCl with a concentration of 0.5mol / L 3 The aqueous solution is added to the closed reaction kettle, and the FeCl used is controlled 3 Fe in aqueous solution 3+ The molar ratio of the total amount to the 2,2'-bipyridine is 1:3, the stirring speed is controlled at 150r / min, and the reaction is refluxed at 75°C for 3h to obtain the complex [Fe(C 10 h 8 N 2 ) 3 ] 3+ The solution.

[0069] 2), to step 1) preparation containing complex [Fe(C 10 h 8 N 2 ) 3 ] 3+ 12Kg dilute hydrochloric acid was added dropwise to the solution, and the rate of addition was controlled to add 1 drop every 2s, while reducing the rotation speed to 50r / min. After the addition, the pH value of the detection system was 1.67.

[0070] 3) Cool to room temperature, then add 70Kg of hydrogen peroxide aqueous solution, and mix well to obtain 1# oxidizing agent compositi...

preparation example 2

[0071] Preparation example 2, preparation of oxidizing agent composition

[0072] 1), 4Kg 2,2'-bipyridine and an appropriate amount of FeCl with a concentration of 0.5mol / L 3 The aqueous solution is added to the closed reaction kettle, and the FeCl used is controlled 3 Fe in aqueous solution 3+ The molar ratio of the total amount to the 2,2'-bipyridine is 1:3, the stirring speed is controlled at 150r / min, and the reaction is refluxed at 65°C for 3h to obtain the complex [Fe(C 10 h 8 N 2 ) 3 ] 3+ The solution.

[0073] 2), to step 1) prepared containing complex [Fe(C 10 h 8 N 2 ) 3 ] 3+ Add 5Kg of concentrated hydrochloric acid dropwise to the solution containing complex [Fe(C 10 h 8 N 2 ) 3 ] 3+ The solution is under acidic conditions, the rate of addition is controlled to add 1 drop every 2s, and the rotation speed is reduced to 60r / min at the same time. After the addition is completed, the pH value of the detection system is 1.73.

[0074] 3), then cool to r...

preparation example 3

[0075] Preparation example 3, preparation of oxidizing agent composition

[0076] 1), 5Kg 2,2'-bipyridine and an appropriate amount of FeCl with a concentration of 0.5mol / L 3 The aqueous solution is added to the closed reaction kettle, and the FeCl used is controlled 3 Fe in aqueous solution 3+ The molar ratio of the total amount to the 2,2'-bipyridine is 1:3, the stirring speed is controlled at 150r / min, and the reaction is refluxed at 75°C for 2h to obtain the complex [Fe(C 10 h 8 N 2 ) 3 ] 3+ The solution.

[0077] 2), to step 1) prepared containing complex [Fe(C 10 h 8 N 2 ) 3 ] 3+ Add 29Kg of dilute hydrochloric acid dropwise to the solution containing complex [Fe(C 10 h 8 N 2 ) 3 ] 3+ The solution is acidic, and the rate of addition is controlled to add 1 drop every 2s, while reducing the rotation speed to 50r / min. After the addition, the pH value of the detection system is 2.03.

[0078] 3), then cooled to room temperature, then added 40Kg of tert-butyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com