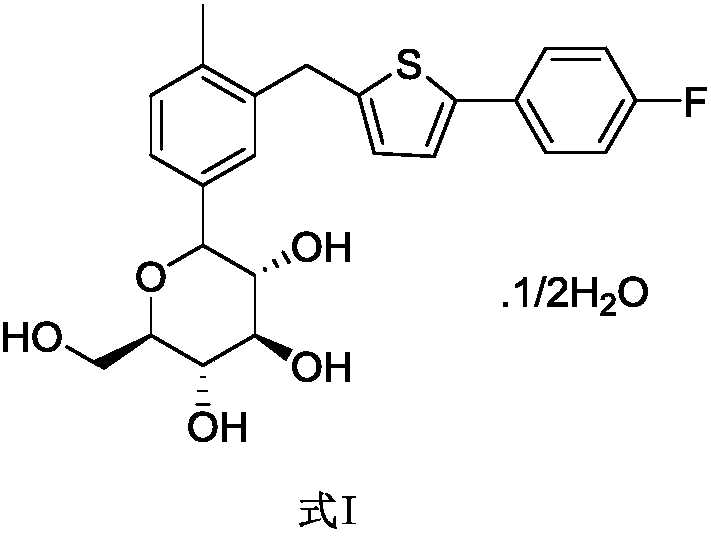

Preparation method of canagliflozin

A technology of glucose and molar ratio, applied in organic chemistry methods, organic chemistry, etc., can solve the problems of low yield, high equipment requirements, high operation safety requirements, etc., and achieve the effect of high product purity, high safety, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

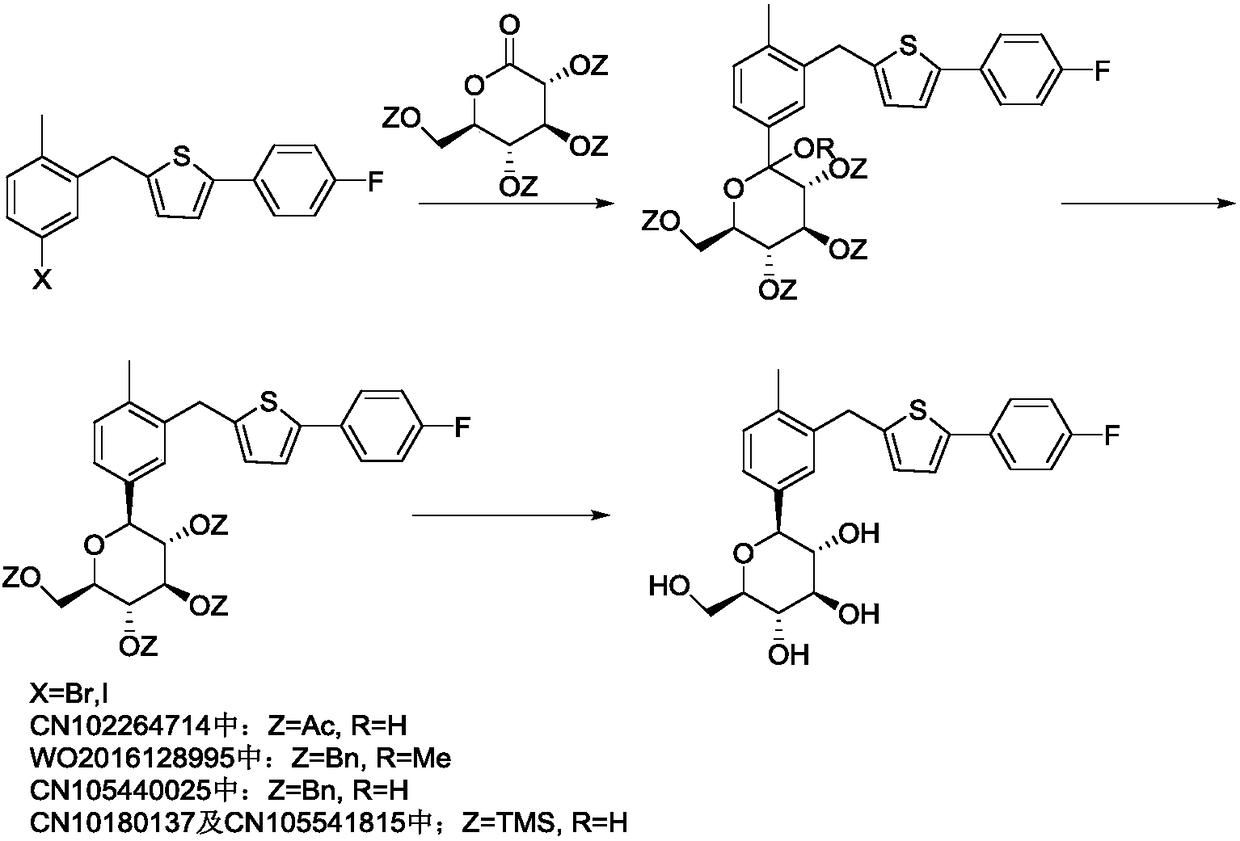

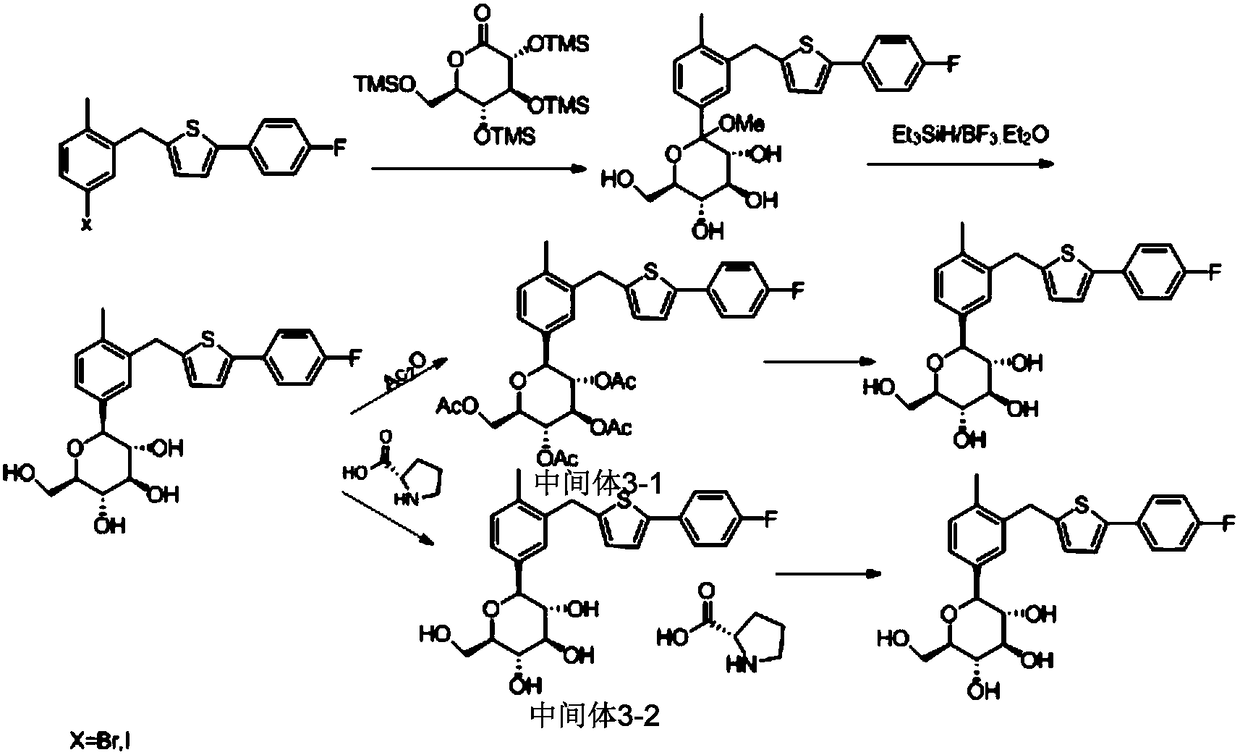

Method used

Image

Examples

Embodiment 1

[0056] The present embodiment is a kind of preparation method of canagliflozin, and described preparation method comprises the following steps:

[0057] 1. Preparation of bromotetraacetylglucose:

[0058] Take a 1L three-necked reaction flask, install a mechanical stirrer, a thermometer and a constant pressure dropping funnel; add 200ml of dichloromethane, 50g (0.2775mol) of d-glucose, 140.2g (1.3875mol) of N-methylmorpholine, and 3.4g (0.0275mol) DMAP was stirred until dissolved; the temperature was lowered to 0-5°C, and 141.6g (1.3875mol) acetic anhydride was added slowly, and the reaction was continued for 2 hours after completion;

[0059] Heat up to distill off the solvent, add 400g of water to the reaction flask after completion, stir to precipitate solid, filter and wash, and vacuum dry to obtain 105.2g of pentaacetylglucose, with a yield of 97.1%;

[0060] Take a 1L three-necked reaction flask, install a mechanical stirrer, a thermometer and a constant pressure droppi...

Embodiment 2

[0068] 1. Preparation of bromotetraacetylglucose:

[0069] Take a 1L three-necked reaction flask, install mechanical stirring, thermometer and constant pressure dropping funnel; add 200ml methylene chloride, 50g (0.2775mol) d-glucose, 154.5g (1.5263mol) triethylamine, 3.4g (0.0275mol) ) DMAP was stirred until dissolved; the temperature was lowered to 0-5°C, and 155.8g (1.5263mol) of acetic anhydride was slowly added, and the reaction was continued for 2 hours after completion;

[0070] Heat up and distill off the solvent, add 450g of water to the reaction flask after completion, stir to precipitate solid, filter and wash, and dry in vacuo to obtain 104.4g of pentaacetylglucose with a yield of 96.4%;

[0071] Take a 1L three-necked reaction flask, install a mechanical stirrer, a thermometer and a constant pressure dropping funnel, add 80g (0.2050mol) of pentaacetylglucose dissolved in 200ml of dichloromethane, cool down to 0-10°C, and slowly add 30% hydrogen dropwise Bromic ac...

Embodiment 3

[0079] The present embodiment is a kind of preparation method of canagliflozin, and described preparation method comprises the following steps:

[0080] 1. Preparation of bromotetraacetylglucose:

[0081] Take a 1L three-necked reaction flask, install a mechanical stirrer, a thermometer and a constant pressure dropping funnel; add 200ml of dichloromethane, 50g (0.2775mol) of d-glucose, 100.1g (1.6650mol) of ethylenediamine, 2.7g (0.0222mol) of ) Stir the DMAP until dissolved; cool down to 0-5°C, slowly add 170.0g (1.6650mol) acetic anhydride, and continue the reaction for 2 hours after completion;

[0082]Heat up and distill off the solvent, add 500g of water to the reaction flask after completion, stir to precipitate solid, filter and wash, and vacuum dry to obtain 103.5g of pentaacetylglucose, yield 95.5%;

[0083] Take a 1L three-necked reaction flask, install a mechanical stirrer, a thermometer and a constant pressure dropping funnel, add 100g (0.2563mol) of pentaacetylgl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com