High hardness damping rubber and preparation method thereof

A shock-absorbing rubber and high-hardness technology, which is applied in the field of rubber products, can solve problems such as high fluidity requirements, difficulty in applying molding processes, and high flow resistance of raw materials for high-hardness products, so as to achieve good mechanical properties, simplify the pre-forming process, The effect of reducing the production link

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

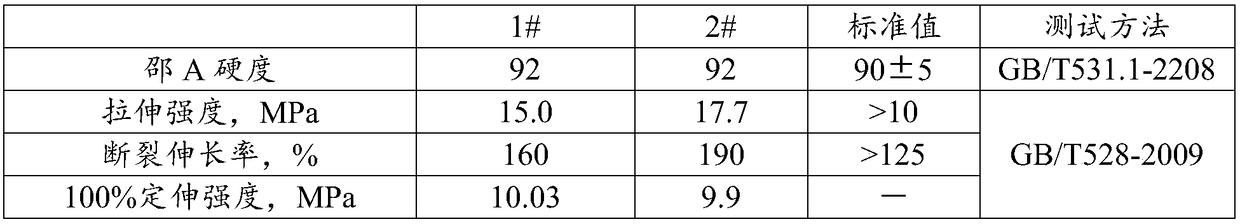

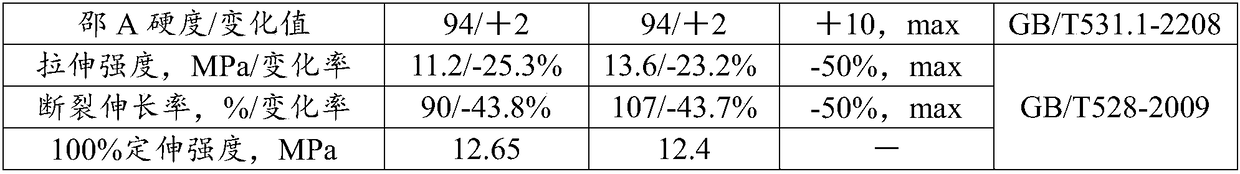

Examples

Embodiment 1

[0028] An embodiment of the high-hardness shock-absorbing rubber of the present invention, the high-hardness shock-absorbing rubber in this embodiment contains the following components by weight:

[0029] 100 parts of raw rubber (3# natural smoke rubber: NR), 15 parts of super wear-resistant carbon black (N220), 40 parts of high wear-resistant carbon black (N330), 40 parts of fast extruded carbon black (N550), 1 Rhine powder 10 parts of glyceryl methacrylate, 5 parts of zinc oxide (ZnO purity ≥ 99.7%), 2 parts of stearic acid (SA), 1 part of p-phenylenediamine anti-aging agent (4010), 1 part of ketamine anti-aging agent ( 2 parts of RD), 2 parts of sulfur, 0.5 parts of 2-mercaptobenzothiazole, 0.8 parts of dibenzothiazole disulfide, and 1.4 parts of N-cyclohexyl-2-benzothiazole sulfenamide.

[0030] The preparation method of the high-hardness shock-absorbing rubber described in this example is as follows: mix the ingredients uniformly to obtain a mixture; automatically feed th...

Embodiment 2

[0032] An embodiment of the high-hardness shock-absorbing rubber of the present invention, the high-hardness shock-absorbing rubber in this embodiment contains the following components by weight:

[0033] Raw rubber (3# natural smoke rubber: NR) 100 parts, super wear-resistant carbon black (N220) 12 parts, high wear-resistant carbon black (N330) 35 parts, fast extrusion carbon black (N550) 35 parts, Rhine powder 0.8 8 parts, 8 parts of glyceryl methacrylate, 4 parts of zinc oxide (ZnO purity ≥ 99.7%), 1.5 parts of stearic acid (SA), 0.8 parts of p-phenylenediamine anti-aging agent (4010), 0.8 part of ketamine anti-aging agent ( 1.5 parts of RD), 1.5 parts of sulfur, 0.4 parts of 2-mercaptobenzothiazole, 0.6 parts of dibenzothiazole disulfide, and 1.2 parts of N-cyclohexyl-2-benzothiazole sulfenamide.

[0034] The preparation method of the high-hardness shock-absorbing rubber described in this example is as follows: mix the ingredients uniformly to obtain a mixture; automatical...

Embodiment 3

[0036] An embodiment of the high-hardness shock-absorbing rubber of the present invention, the high-hardness shock-absorbing rubber in this embodiment contains the following components by weight:

[0037] 100 parts of raw rubber (3# natural smoke rubber: NR), 18 parts of super wear-resistant carbon black (N220), 45 parts of high wear-resistant carbon black (N330), 45 parts of fast extruded carbon black (N550), 1.2 parts of Rhine Powder 12 parts of glyceryl methacrylate, 6 parts of zinc oxide (ZnO purity ≥ 99.7%), 2.5 parts of stearic acid (SA), 1.2 parts of p-phenylenediamine anti-aging agent (4010), ketone-amine anti-aging agent ( 2.5 parts of RD), 2.5 parts of sulfur, 0.6 parts of 2-mercaptobenzothiazole, 1.0 parts of dibenzothiazole disulfide, and 1.6 parts of N-cyclohexyl-2-benzothiazole sulfenamide.

[0038] The preparation method of the high-hardness shock-absorbing rubber described in this example is as follows: mix the ingredients uniformly to obtain a mixture; automat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com