Surface treatment method for improving plug-in performance of electric initiating explosive device

A technology of surface treatment and electro-technical products, which is applied in the electroplating of sealing parts for electro-technical products, and in the field of surface treatment where electro-technical products for aerospace have special requirements for plugging performance, and can solve the problem that is not conducive to the mass production of sealing parts , not suitable for surface treatment, poor versatility, etc., to achieve the effect of saving raw materials, promoting uniform nucleation, and bright surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

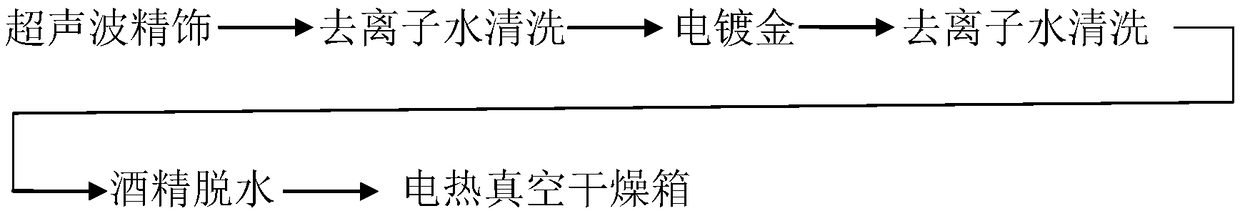

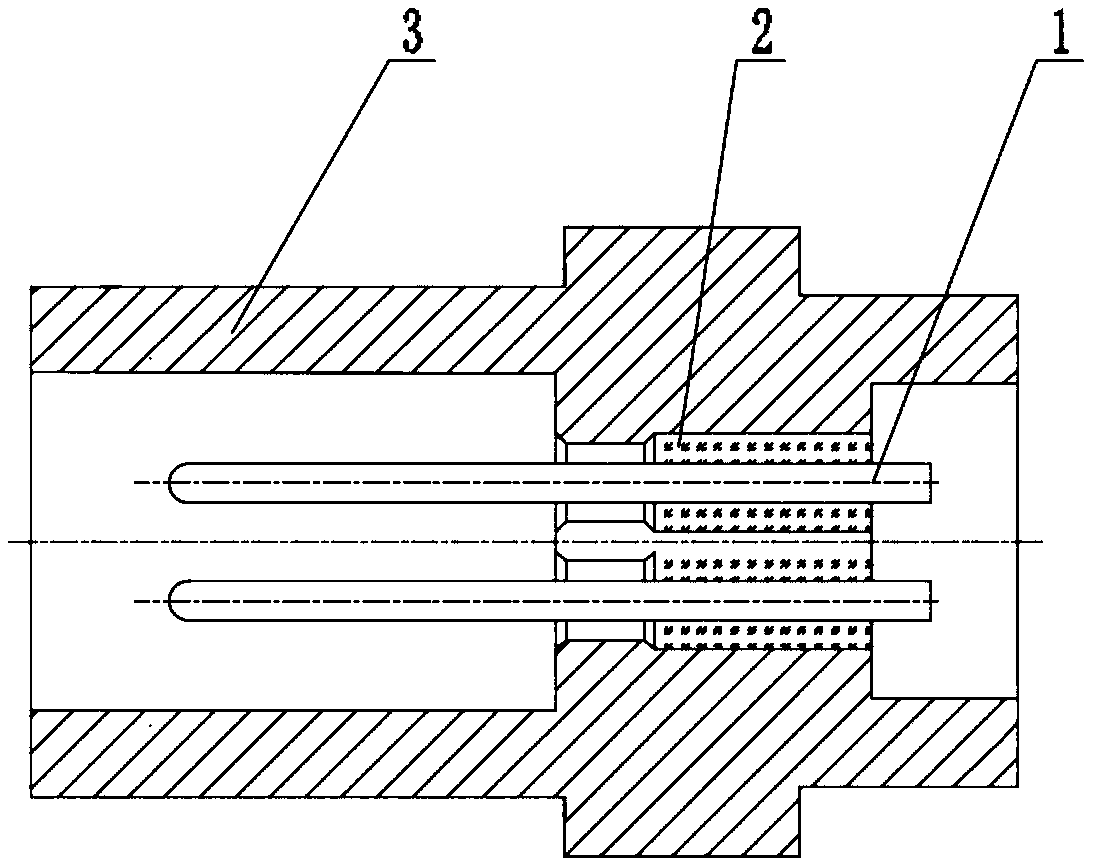

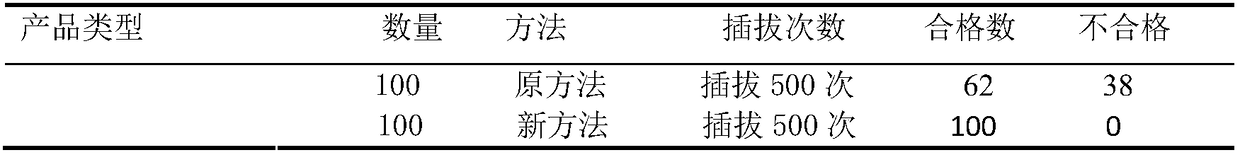

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

[0027] There are two aspects to be considered to improve the plugging life of the sealing parts of electrical pyrotechnics. Generally, the higher the hardness of the surface coating of the pins at the plugging end, the better its wear resistance, the longer the plugging life of the sealing parts, and the higher the reliability. , so the first consideration is to increase the hardness of the gold-plated layer on the surface of the contact pin of the sealing part. At present, in the market, alloying elements are added to the electroplating solution to form an alloy coating to increase the hardness of the gold coating. This is feasible for general electrical pyrotechnics seals that do not require high electrical performance, but seals that require high electrical performance (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com