Pulping process by using grasses as raw material

A grass plant and process technology, applied in the field of papermaking, can solve the problems of difficult recovery and large pollution of pulping residue, and achieve the effects of less alkali consumption, good cooking effect and short cooking time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

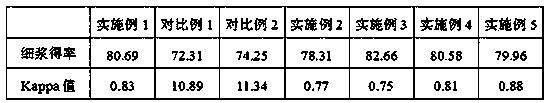

Examples

Embodiment 1

[0022] S1 raw material preparation, removing impurities after the reed raw material is chopped;

[0023] S2 primary cooking: carry out primary cooking according to the liquid ratio of 1:4, the cooking temperature is 80°C, the cooking time is 15min, washed with water, the cooking liquid used is composed of the following components in mass percentage: 6% sodium hydroxide, 0.5% sodium sulfite, Sodium sulfide 1.6%, anthraquinone 0.5%, sodium dodecylsulfonate 0.03%, the balance water;

[0024] S3 secondary cooking: carry out secondary cooking according to the liquid ratio of 1:5, the cooking temperature is 60°C, the cooking time is 15min, and washed with water. The cooking liquid used is a mixed enzyme liquid composed of enzyme liquid I and enzyme liquid II at a mass ratio of 1.3:1 and Composition of water, wherein, the consumption of described water is 150 times of mixed enzyme solution.

Embodiment 2

[0026] S1 raw material preparation, removing impurities after the reed raw material is chopped;

[0027] S2 primary cooking: carry out primary cooking according to the liquid ratio of 1:4, the cooking temperature is 75°C, the cooking time is 20min, washed with water, the cooking liquid used is composed of the following components in mass percentage: 6% sodium hydroxide, 0.5% sodium sulfite, Sodium sulfide 1.6%, anthraquinone 0.5%, sodium dodecylsulfonate 0.03%, the balance water;

[0028] S3 secondary cooking: carry out secondary cooking according to the liquid ratio of 1:5, the cooking temperature is 55°C, the cooking time is 15min, and washed with water. The cooking liquid used is a mixed enzyme liquid composed of enzyme liquid I and enzyme liquid II at a mass ratio of 2.1:1 and Composition of water, wherein, the consumption of described water is 150 times of mixed enzyme solution.

Embodiment 3

[0030] S1 raw material preparation, removing impurities after the reed raw material is chopped;

[0031] S2 primary cooking: carry out primary cooking according to the liquid ratio of 1:5, the cooking temperature is 85°C, the cooking time is 10min, and washed with water. The cooking liquid used is composed of the following components in terms of mass percentage: 8% sodium hydroxide, 0.6% sodium sulfite, Sodium sulfide 2%, anthraquinone 0.5%, sodium dodecyl sulfonate 0.07%, the balance water;

[0032] S3 secondary cooking: carry out secondary cooking according to the liquid ratio of 1:6, the cooking temperature is 65°C, the cooking time is 15min, and washed with water. The cooking liquid used is a mixed enzyme liquid composed of enzyme liquid I and enzyme liquid II in a mass ratio of 1.5:1, An enzyme stabilizer and water, wherein the concentration of the enzyme stabilizer (glycerol) in the cooking liquid is 1 mmol / L, and the amount of the water is 200 times that of the mixed en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com