Method of improving detecting sensitivity of micro-fluidic chip by non-contact conducting method

A microfluidic chip, non-contact conductance technology, applied in material impedance and other directions, can solve the problems of limited sensitivity improvement, high cost, and complicated operation, and achieve the effects of high sensitivity, low cost, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, the method is used for the concentration detection of medicine---galantamine

[0038] This embodiment provides a method for improving the detection sensitivity of the non-contact conductometric method of the microfluidic chip. Since the drug galantamine is an ionizable substance, the detection of galantamine is taken as an example to illustrate the method for improving the detection sensitivity of the non-contact conductivity method of the microfluidic chip.

[0039] The method for improving the detection sensitivity of the non-contact conductometric method of the microfluidic chip in this embodiment includes the following steps:

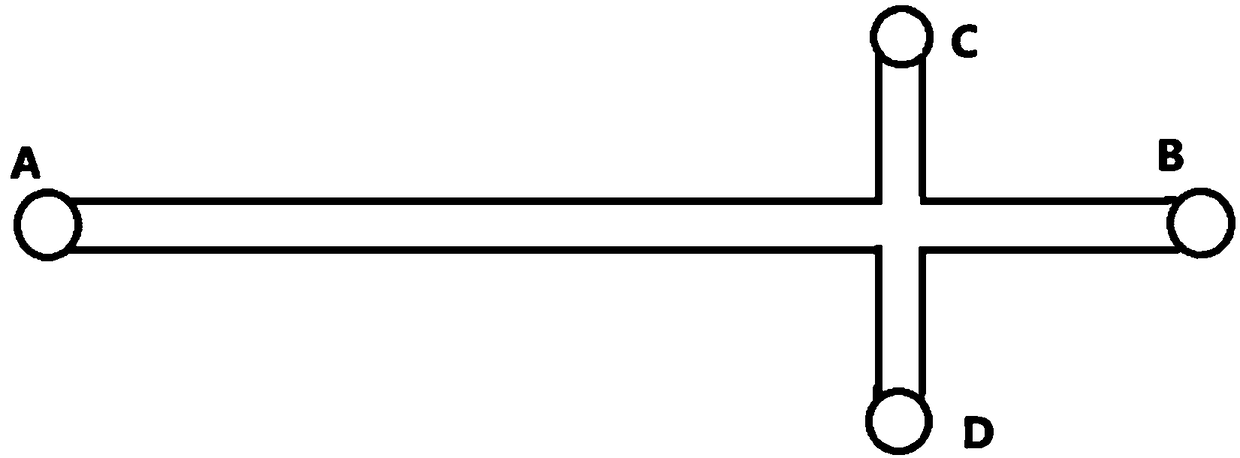

[0040] (1) Take the microfluidic chip (conventional cross-shaped PMMA microfluidic chip, see the structure figure 1 ), the microfluidic chip used in this embodiment is a reusable microfluidic chip.

[0041] (2) First use sodium hydroxide solution to activate the sampling channel and separation channel of the microfluidic chi...

Embodiment 2

[0048] This embodiment is a modification example of embodiment 1. Compared with embodiment 1, the main change is that in step (4), the buffer solution containing 40% ethanol by volume is added to the buffer storage tank.

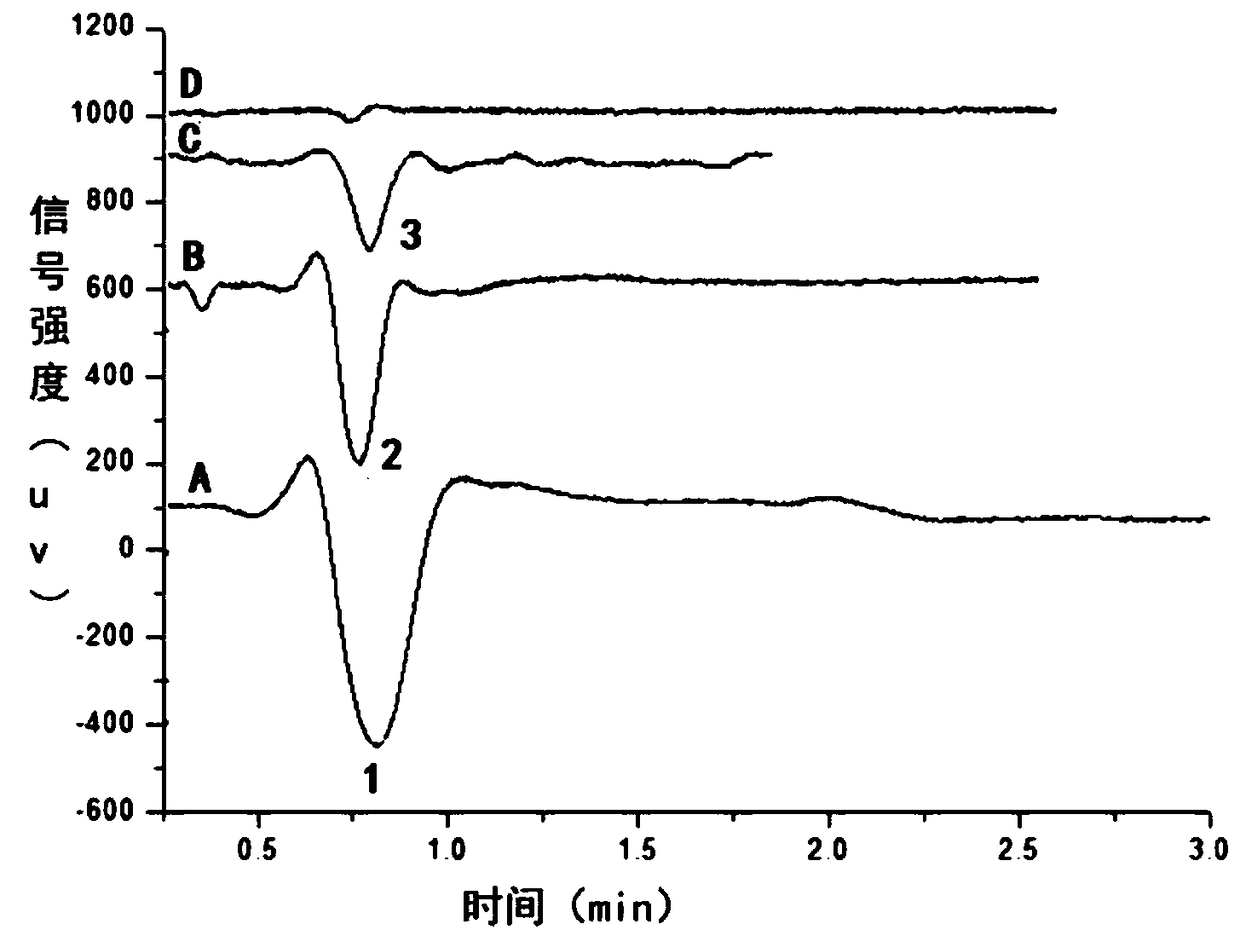

[0049] See the test results image 3 ,according to image 3 From the chromatogram shown in A, it can be seen that when the volume percentage of ethanol is 40%, the detection signal intensity is amplified.

Embodiment 3

[0051] This embodiment is a modification example of embodiment 1. Compared with embodiment 1, the main change is that in step (4), the buffer solution containing 30% ethanol by volume is added to the buffer storage tank.

[0052] See the test results image 3 ,according to image 3 From the chromatogram shown in B, it can be seen that when the volume percentage of ethanol is 30%, the detection signal intensity is amplified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com