Castable silicone rubber base temperature resistant shielding material and preparation method thereof

A technology of shielding material and silicone rubber is applied in the field of castable silicone rubber-based temperature-resistant shielding material and its preparation, which can solve the problems of complex process and achieve the effects of low hardness, small expansion and contraction, and excellent high and low temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

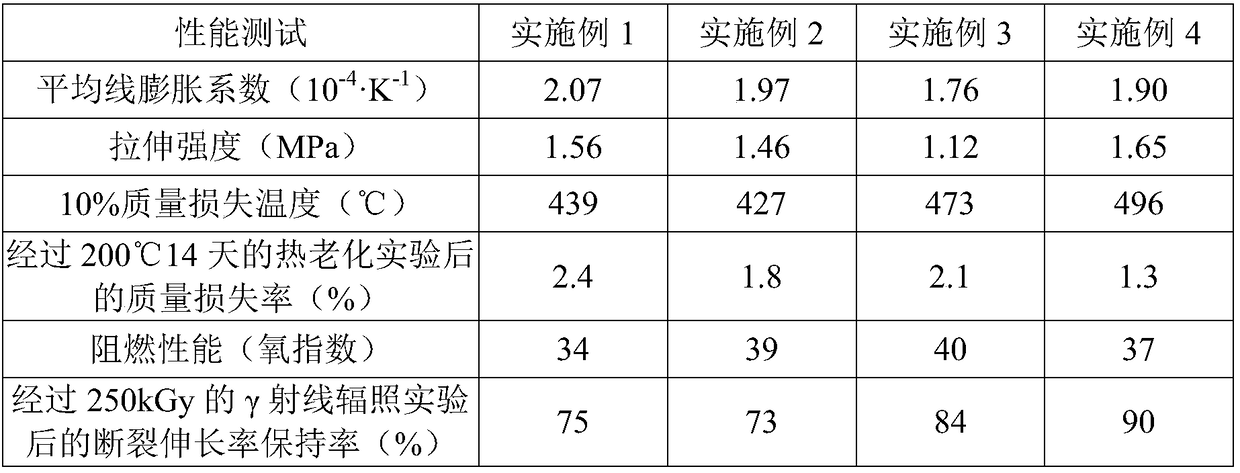

Examples

Embodiment 1

[0031] This embodiment provides a castable silicone rubber-based heat-resistant shielding material, the raw material composition of which includes: 100 parts by weight of hydroxyl-terminated dimethyl silicone oil (weight-average molecular weight: 48,000), 7.5 parts by weight of fumed silica, carbonized 4 parts by weight of boron, 60 parts by weight of magnesium hydroxide, 3 parts by weight of ethyl orthosilicate, and 2 parts by weight of dibutyltin dilaurate.

[0032] Above-mentioned boron carbide is modified according to the following steps:

[0033] Dissolve an appropriate amount of boron carbide powder in a NaOH solution with a concentration of 5 mol / L, stir in an oil bath at 120°C for 24 hours, rinse and filter until neutral, and dry in an oven at 90°C for 8 hours; the above dried boron carbide powder Prepare a suspension, stir magnetically at 70°C for 30 minutes; add the silane coupling agent to the suspension, stir and reflux at 70°C for 4 hours, then dry in an oven at 9...

Embodiment 2

[0041] This embodiment provides a pourable silicone rubber-based heat-resistant shielding material, the raw material composition of which includes: 100 parts by weight of hydroxyl-terminated dimethyl silicone oil (weight average molecular weight: 48,000), 7.5 parts by weight of fumed silica, carbonized 4 parts by weight of boron, 120 parts by weight of magnesium hydroxide, 3 parts by weight of ethyl orthosilicate, and 2 parts by weight of dibutyltin dilaurate.

[0042] The modification treatment of the above-mentioned boron carbide is the same as in Example 1.

[0043] The pourable silicone rubber-based heat-resistant shielding material is prepared through the following steps:

[0044] Preparation of component A: add fumed white carbon black to an appropriate amount of hydroxy silicone oil, stir mechanically at room temperature for 30 minutes, then add magnesium hydroxide and modified boron carbide in turn, vacuum defoam for 1 hour, and finally add ethyl orthosilicate, Stir e...

Embodiment 3

[0050] This embodiment provides a pourable silicone rubber-based heat-resistant shielding material, the raw material composition of which includes: 100 parts by weight of hydroxyl-terminated dimethyl silicone oil (weight average molecular weight: 48,000), 7.5 parts by weight of fumed silica, carbonized 100 parts by weight of boron, 3 parts by weight of ethyl orthosilicate, and 2 parts by weight of dibutyltin dilaurate.

[0051] The modification treatment of the above-mentioned boron carbide is the same as in Example 1.

[0052] The pourable silicone rubber-based heat-resistant shielding material is prepared through the following steps:

[0053] Preparation of component A: add fumed white carbon black to an appropriate amount of hydroxy silicone oil, stir mechanically at room temperature for 30 minutes, then add modified boron carbide, vacuum degassing for 1 hour, and finally add tetraethyl orthosilicate, stir evenly at room temperature for 30 minutes, Vacuum defoaming for 0.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com