Surface imprinting Fe<3+> potassium tetratitanate crystal whisker adsorption agent and preparation method thereof

A potassium tetratitanate, surface imprinting technology, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., can solve the problems of inability to use industrialized large-scale production, high preparation and operation costs, and small scale of wastewater treatment, Achieve the effect of promoting effective dispersion, excellent adsorption capacity, and improving surface polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

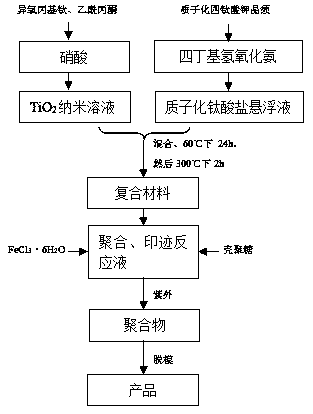

[0027] A surface imprinted Fe 3+ Preparation method of potassium tetratitanate whisker adsorbent, such as figure 1 As shown, the synthesis process steps include:

[0028] 1. Add 0.1 mol of titanium isopropoxide and 0.2 mol of acetylacetone to 180 mL of 0.015 mol / L nitric acid solution, and stir at 60°C for 8 hours to prepare TiO 2 Nano sol solution.

[0029] 2. Take a certain amount of potassium tetratitanate whiskers, soak in 1mol / L hydrochloric acid solution to protonate the surface, then filter, wash, and dry. Take 5.0 g of protonated potassium tetratitanate whiskers, soak in 250 mL of a solution containing 14.8 mmol of tetrabutylammonium hydroxide, and ultrasonically disperse the suspension for 2 hours to obtain a protonated titanate suspension.

[0030] 3. Put 10mL of TiO prepared in step 1 2 The nanosol solution was added dropwise to 100 mL of the protonated titanate suspension prepared in step 2, and stirred at 60°C for 24 hours. The formed product was filtered, washed, dried,...

Embodiment 2

[0034] This embodiment adopts the preparation method of embodiment 1 for implementation, the difference lies in:

[0035] In step 4, accurately weigh 0.4849g (0.0018mol) of FeCl 3 • 6H 2 O was dissolved in 150.0 mL of 0.2mol / L acetic acid solution under stirring and heating conditions, and then 1.50 g of chitosan powder was added to the reaction solution. The reaction solution was stirred and refluxed for 1.0 hour.

Embodiment 3

[0037] This example is implemented using the preparation method of Example 1. The difference is that:

[0038] In step 4, accurately weigh out 0.9650g (0.0036mol) of FeCl 3 • 6H 2 O was dissolved in 150.0 mL of 0.2mol / L acetic acid solution under stirring and heating conditions, and then 1.50 g of chitosan powder was added to the reaction solution. The reaction solution was stirred and refluxed for 1.0 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com