Preparation method of nano gadolinium oxide with grain size being 80-100nm

A nanometer gadolinium oxide, particle size technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc. problem, to avoid large agglomeration, good dispersibility, and good particle dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

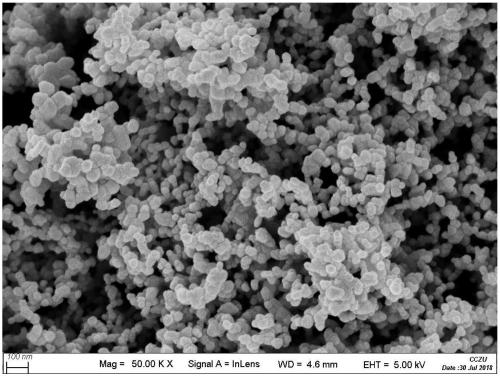

Embodiment 1

[0025] This specific embodiment adopts the following technical scheme to prepare nano-gadolinium oxide powder with a particle size of 80-100 nm: the ambient temperature is controlled to 26° C. by an external temperature control device (which may be an air conditioner). Take a high-concentration gadolinium chloride solution, add pure water to dilute and prepare a gadolinium chloride solution with a concentration of 0.3mol / L, then put 91.95L of a gadolinium chloride solution with a concentration of 0.3mol / L into a septum reactor, and separate Circulating ice water was introduced into the jacket to control the temperature of the solution system in the jacketed reactor to 2°C. Then weigh 500 grams of polyethylene glycol 20000 and dissolve it with pure water to form 2L of solution, add it to the above-mentioned spacer reaction kettle, and after stirring for 30 minutes, evenly spray and drop the sodium bicarbonate solution with a concentration of 0.3mol / L and a temperature of 2°C In...

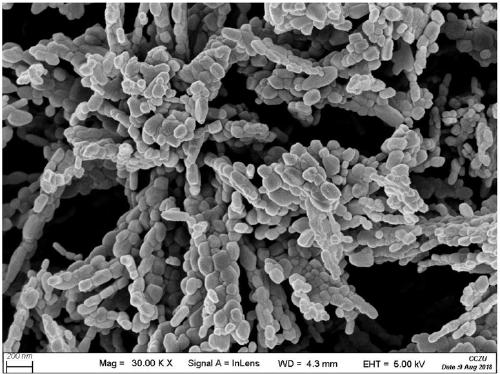

Embodiment 2

[0029] This specific embodiment adopts the following technical solution to prepare nano-gadolinium oxide powder with a particle size of 80-100 nm: the ambient temperature is controlled to 28° C. by an external temperature control device (which may be an air conditioner). Take a high-concentration gadolinium chloride solution, add pure water to dilute and prepare a gadolinium chloride solution with a concentration of 0.2mol / L, then put 275.86L of a gadolinium chloride solution with a concentration of 0.2mol / L into the reaction kettle with a septum, separate Circulating ice water was introduced into the jacket to control the temperature of the solution system in the jacket reactor to 0°C. Then weigh 1500 grams of polyethylene glycol 10000 and dissolve it with pure water to form a 6L solution, add it to the above-mentioned spacer reactor, stir for 30 minutes, and evenly spray and drop the sodium bicarbonate solution with a concentration of 0.2mol / L and a temperature of 0°C Into t...

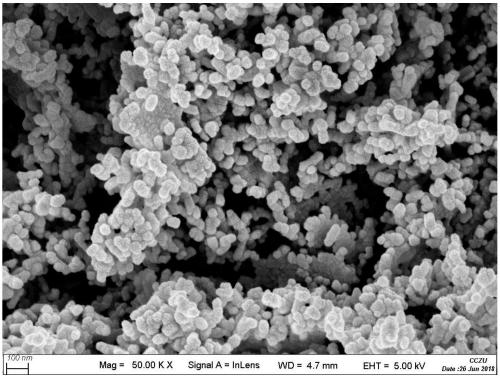

Embodiment 3

[0033] This specific embodiment adopts the following technical solution to prepare nano-gadolinium oxide powder with a particle size of 80-100 nm: the ambient temperature is controlled to 27° C. by an external temperature control device (which may be an air conditioner). Take a high-concentration gadolinium chloride solution, add pure water to dilute and prepare a gadolinium chloride solution with a concentration of 0.1mol / L, and then put 441.38L of a gadolinium chloride solution with a concentration of 0.1mol / L into the spacer for reaction In the kettle, circulating ice water was passed through the spacer to control the temperature of the solution system at 3°C. Then weigh 960 grams of polyethylene glycol 10000 and dissolve it with pure water to form a solution of 3.84 L, add it to the above-mentioned spacer reaction kettle, and after stirring for 30 minutes, spray the sodium bicarbonate solution with a concentration of 0.4mol / L and a temperature of 3°C evenly. Add it to a sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com