Method for treating wastewater produced by ammoximation process for caprolactam

A technology of caprolactam amidoxime and production wastewater, which is applied in the fields of special compound water treatment, water/sewage treatment, natural water treatment, etc., can solve the problems of complicated operation and high equipment investment, reduce consumption, reduce investment and operating costs, reduce Effects of biochemical stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The waste water of caprolactam ammoximation production process in a chemical enterprise has a COD of 2800 mg / L and a pH of 2.0 after oxidation by the Fenton method.

[0023] The caprolactam ammoximation production process wastewater is processed according to the following steps:

[0024] 1) Caprolactam ammoximation production wastewater with 5m 3 / h flow rate, enter the adsorption column filled with styrene-based macroporous adsorption resin (XDA-1G, produced by Xi'an Lanxiao Technology New Materials Co., Ltd.) (adsorption column specification: ¢1200*3000mm, filling volume 2.5 cubic meters) ; The organic matter in the caprolactam ammoximation production wastewater is removed by the functional polymer adsorption material. After 20 hours of operation, the COD of the effluent is greater than 300mg / L, and the adsorption is stopped.

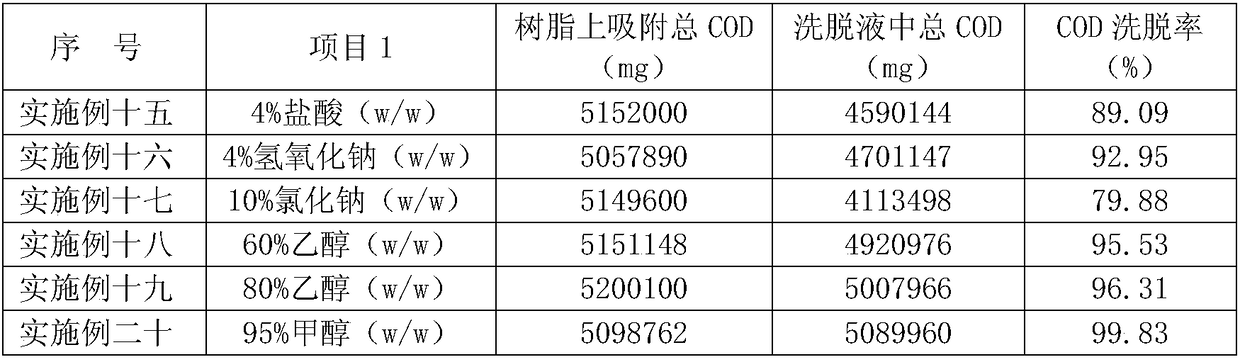

[0025] 2) After the adsorption is completed, pass through 70% w / w ethanol solution for elution, the performance of the resin is restored, and...

Embodiment 2

[0027] The caprolactam ammoximation production process wastewater of a chemical company has a COD of 5000 mg / L and a pH of 5.0.

[0028] The caprolactam ammoximation production process wastewater is processed according to the following steps:

[0029] 1) Caprolactam ammoximation production wastewater with 10m 3 / h flow rate, enter the adsorption column filled with styrene-based macroporous adsorption resin (XDA-200, produced by Xi'an Lanxiao Technology New Materials Co., Ltd.) (the specification of the adsorption column: ¢2000*5000mm, the filling volume is 12 cubic meters. There are three resin columns in total, two in series and one in standby); the organic matter in the caprolactam ammoximation production wastewater is removed by the functional polymer adsorption material, and after 12 hours of operation, the first column stops the adsorption. The second and third columns are connected in series for adsorption and the first column for elution.

[0030] 2) After the adsorpt...

Embodiment 3

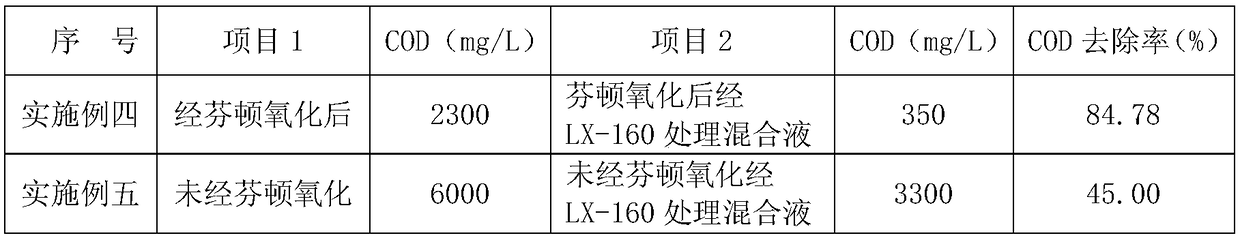

[0032] The caprolactam ammoximation production process wastewater of a chemical company has a COD of 3500 mg / L and a pH of 1.5 after oxidation by the Fenton method.

[0033] The caprolactam ammoximation production process wastewater is processed according to the following steps:

[0034] Caprolactam ammoximation production waste water with 120m 3 / h flow rate, enter the continuous ion exchange device filled with styrene macroporous adsorption resin (XDA-1, Xi'an Lanxiao Technology New Materials Co., Ltd.) (adsorption column specification: ¢1600*1700mm, single column packing volume 2.6 Cubic meters, 20 columns, divided into different areas to realize the simultaneous operation of adsorption and elution processes, and realize the continuous operation of valve switching through automatic control. Its use principle refers to the authorized patent applied by Lanxiao Technology, patent publication number CN202516562U); caprolactam Ammoximation production wastewater passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com