Flame-retarding toughened biodegradable polylactic acid material and preparation method thereof

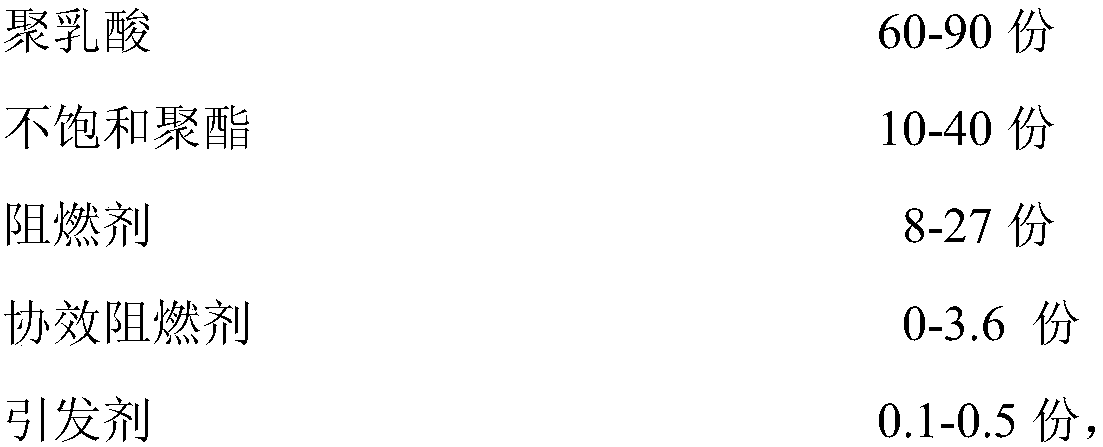

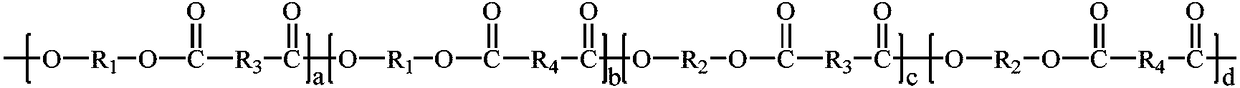

A polylactic acid material and a biodegradable technology are applied in the field of flame retardant, toughening and biodegradable polylactic acid materials and their preparation, which can solve the problem of destroying the toughening effect of the toughening agent and affecting the dispersion behavior of the polylactic acid base material and the toughening agent. , destroying the chemical structure of the toughening agent, etc., to achieve the effect of improving melt viscosity, toughness, and network structure stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

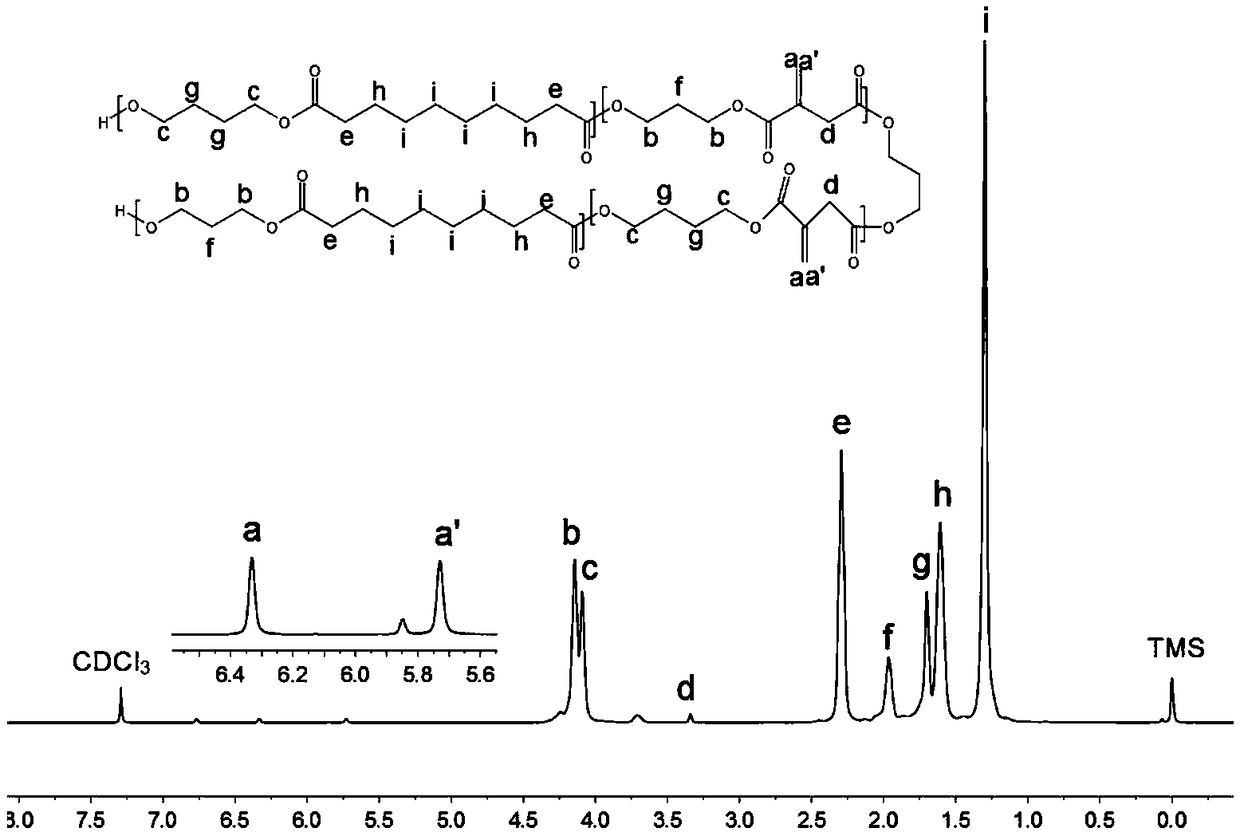

Image

Examples

Embodiment 1

[0032] Take 16 parts of 1,3-propanediol, 13 parts of 1,4-butanediol, 5 parts of itaconic acid, and 66 parts of 1,10-sebacic acid in a three-necked flask equipped with mechanical stirring, nitrogen inlet and suction outlet , After stirring and reacting at 170°C under normal pressure nitrogen atmosphere for 4h, inject 0.2 part of catalyst tetrabutyl titanate, evacuate until the atmospheric pressure in the bottle is lower than 200Pa, slowly raise the temperature to 230°C, continue stirring and react for 3h, then stop the reaction. The number average molecular weight of the obtained unsaturated polyester is 2.9*10 4 Da, weight average molecular weight is 5.4*10 4 Da, molecular weight distribution is 1.9, referred to as unsaturated polyester #1 for short.

Embodiment 2

[0034] Take 12 parts of 1,3-propanediol, 23 parts of 1,4-butanediol, 8 parts of maleic acid, and 57 parts of 1,10-sebacic acid in a three-necked flask equipped with mechanical stirring, nitrogen inlet and exhaust outlet After stirring and reacting for 4.5 hours at 175°C under normal pressure nitrogen atmosphere, inject 0.2 part of tetrabutyl titanate catalyst, evacuate until the atmospheric pressure in the bottle is lower than 200Pa, slowly raise the temperature to 220°C, continue to stir and react for 3.5 hours before stopping the reaction. The number average molecular weight of the obtained unsaturated polyester is 4.1*10 4 Da, the weight average molecular weight is 8.9*10 4 Da, molecular weight distribution is 2.2, referred to as unsaturated polyester #2 for short.

Embodiment 3

[0036] Take 29 parts of 1,5-pentanediol, 13 parts of 1,4-butanediol, 9 parts of itaconic acid, and 49 parts of 1,8-suberic acid in the three ports equipped with mechanical stirring, nitrogen inlet and exhaust outlet In the flask, after stirring and reacting at 185°C for 2h under normal pressure nitrogen atmosphere, inject 0.2 part of catalyst tetrabutyl titanate, evacuating until the atmospheric pressure in the flask is lower than 200Pa, slowly heating up to 230°C, continue stirring and reacting for 2h, then stop the reaction. The number average molecular weight of the obtained unsaturated polyester is 4.3*10 4 Da, the weight average molecular weight is 9.2*10 4 Da, molecular weight distribution is 2.1, referred to as unsaturated polyester #3 for short.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com