UV ink spraying white ink

An inkjet ink, white technology, applied in the field of UV white inkjet ink, to achieve the effect of good curing adhesion, good stability and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

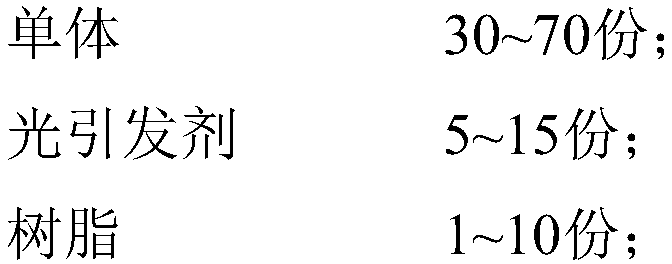

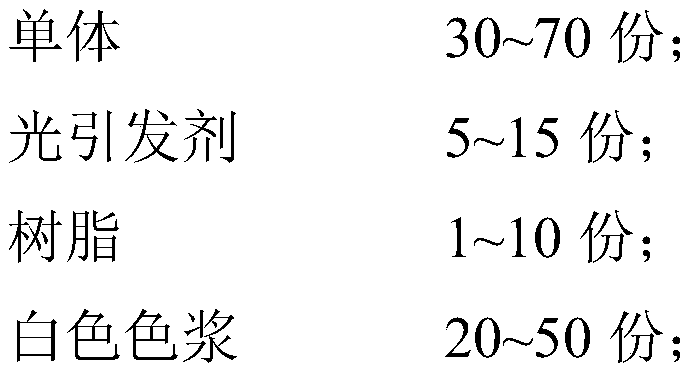

Method used

Image

Examples

preparation example Construction

[0046] In the present invention, the preparation method of the white color paste preferably comprises the following steps:

[0047] (1) dissolving the dispersant by using the color paste monomer to obtain a pre-solution;

[0048] (2) Stir and mix the pre-solution obtained in the step (1) with the pigment, color paste additive, and obtain a pre-dispersion;

[0049] (3) Grinding and filtering the predispersed liquid obtained in the step (2) to obtain a white slurry.

[0050] The invention adopts colorant monomer to dissolve the dispersant to obtain a pre-solution.

[0051] The present invention has no particular limitation on the specific implementation of the dissolving and dispersing agent for the color paste monomer, and the methods well known to those skilled in the art can be adopted.

[0052] After the pre-solution is obtained, the present invention stirs and mixes the pigment, color paste additives and the pre-solution to obtain the pre-dispersion liquid.

[0053] In t...

Embodiment 1

[0064]The UV white inkjet ink consists of 40 parts by mass of tetrahydrofurfuryl acrylate, 10 parts of N,N-dimethylacrylamide, and 4.0 parts of tri(ethoxy)trimethylolpropane triacrylate , 3.0 parts of epoxy acrylic oligomers, wherein the molecular weight of epoxy acrylic oligomers > 1500, 3.0 parts of vinyl acetate resins, wherein the molecular weight of vinyl acetate resins > 8000, 2,4,6-trimethylbenzoyl di 7.0 parts of phenylphosphine oxide, 1.0 parts of 2-benzyl-2-dimethylamino-1-(4-morpholine phenyl) butanone, 1.0 parts of 2,4-diethylthiazolone, BYK-3500 0.2 parts of wet agent, 0.7 parts of BHT stabilizer, 30 parts of color paste, including 11.4 parts of color paste monomer 1,6-hexanediol diacrylate, 13 parts of dispersant BYK-91513, and 0.6 parts of color paste auxiliary agent BHT part and 15 parts of titanium dioxide pigment, wherein the particle diameter of the color paste is 222nm, and the mass ratio of the color paste monomer, dispersant, color paste auxiliary agent a...

Embodiment 2

[0066] The UV white inkjet ink consists of 53.6 parts by mass of benzyl acrylate, 4.0 parts of n(propoxy) glycerol triacrylate, 3.0 parts of polyester acrylic oligomer, wherein polyester acrylic oligomer The molecular weight of the product is >1500, 3.0 parts of polyurethane resin, of which the molecular weight of polyurethane resin is >8000, 7.0 parts of 2,4,6-trimethylbenzoyldiphenylphosphine oxide, and 1.0 parts of 2,4-diethylthiazolone , 1.0 parts of 2-hydroxy-2-methyl-1-phenyl-1-acetone, 0.2 parts of BYK-3500 wetting agent, 0.7 parts of BHT stabilizer, 25 parts of color paste, wherein the color paste includes color paste monomer 1 , 4.5 parts of 6-hexanediol diacrylate, 7.5 parts of dispersant BYK-1688, 0.5 parts of color paste additive BHT and 12.5 parts of titanium dioxide pigment, wherein the particle size of the color paste is 216nm, and the color paste monomer and dispersion in the color paste The mass ratio of agent, color paste additive and titanium dioxide is 33:1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com