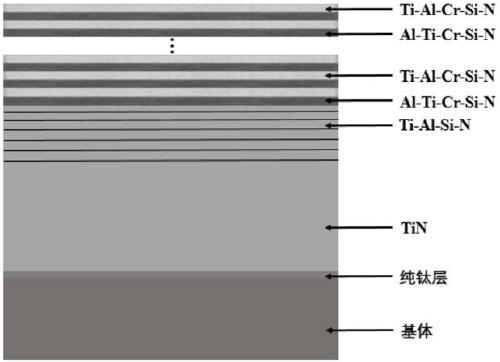

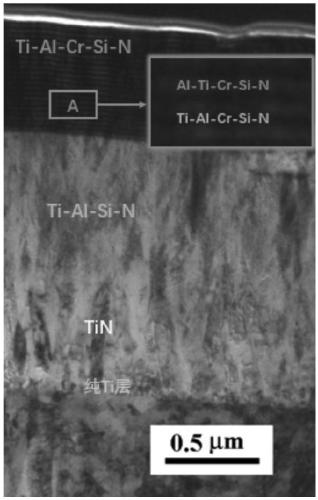

Ti/TiN/TiAlSiN/TiAlCrSiN nanometer multi-layer gradient film and preparation method thereof

A nano-multilayer, gradient film technology, applied in nanotechnology, coating, metal material coating technology and other directions, can solve the problems of low hardness, difference in coating performance, complicated device and process processing, etc., to improve wear resistance. performance and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also proposes a preparation method for the above-mentioned Ti / TiN / TiAlSiN / TiAlCrSiN nano-multilayer gradient film, which specifically includes the following steps:

[0036] (1) Grind and polish the substrate step by step with sandpaper. Then put the substrate into acetone and ultrasonically clean it for 10 minutes. After cleaning, the substrate is cleaned with alcohol, dried and put into the coating vacuum chamber.

[0037] (2) Deposit Ti / TiN / TiAlSiN / TiAlCrSiN nanometer multi-layer gradient film on the substrate treated in step (1) by a multi-arc ion coating machine located in the coating vacuum chamber and a plurality of targets, the plurality of targets being 3 A Ti elemental target with a purity of 99.9%, an Al-Ti-Si alloy target, an Al-Ti alloy target and an Al-Si alloy target. The specific process is as follows:

[0038] (2-1) Place all the targets evenly on both sides of the substrate, and the horizontal distance to the substrate is 360mm. ...

Embodiment 1

[0048] Example 1: The coefficient of friction is 0.02, there is more argon, and the sputtering time is long

[0049] (1) Grind and polish the substrate step by step with sandpaper. Then put the substrate into acetone and ultrasonically clean it for 10 minutes. After cleaning, the substrate is cleaned with alcohol, dried and put into the coating vacuum chamber.

[0050] (2) Deposit Ti / TiN / TiAlSiN / TiAlCrSiN nanometer multi-layer gradient film on the substrate treated in step (1) by a multi-arc ion coating machine located in the coating vacuum chamber and a plurality of targets, the plurality of targets being 3 A Ti elemental target with a purity of 99.9%, an Al-Ti-Si alloy target, an Al-Ti alloy target and an Al-Si alloy target. The specific process is as follows:

[0051] (2-1) Place each target at a distance of 360mm from the substrate, heat the vacuum coating chamber to 400°C, keep it for about 0.5h, and vacuum to ≤4.0×10 -3 Pa.

[0052] (2-2) Deposit Ti as the bottom lay...

Embodiment 2

[0063] Embodiment 2: The binding force is greater than 36N

[0064](1) Grind and polish the substrate step by step with sandpaper. Then put the substrate into acetone and ultrasonically clean it for 10 minutes. After cleaning, the substrate is cleaned with alcohol, dried and put into the coating vacuum chamber.

[0065] (2) Deposit Ti / TiN / TiAlSiN / TiAlCrSiN nanometer multi-layer gradient film on the substrate treated in step (1) by a multi-arc ion coating machine located in the coating vacuum chamber and a plurality of targets, the plurality of targets being 3 A Ti elemental target with a purity of 99.9%, an Al-Ti-Si alloy target, an Al-Ti alloy target and an Al-Si alloy target. The specific process is as follows:

[0066] (2-1) Place each target at a distance of 360mm from the substrate, heat the vacuum coating chamber to 350°C, keep it for about 0.5h, and vacuum to ≤4.0×10 -3 Pa.

[0067] (2-2) Deposit Ti as the bottom layer: open 3 Ti single-substance targets, and close ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com