High-performance underwater welding cable

An underwater welding, high-performance technology, applied in the direction of insulated cables, submarine cables, cables, etc., can solve the problem that the welding line cannot meet the deep sea pressure and impact resistance, so as to improve the tensile strength and waterproofness, and increase the water resistance. performance, stability-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

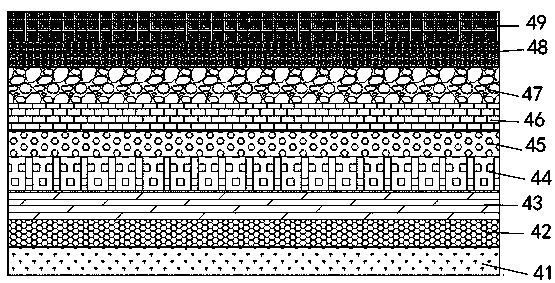

[0035] The waterproof material for submarine cables is composed of the following raw materials in parts by weight: 30 parts of silicate minerals, 15 parts of ethylene-vinyl acetate copolymer, 5 parts of asphalt, 11 parts of nitrile rubber, and 10 parts of m-phenylenediamine , 7 parts of epoxy resin, 2 parts of tourmaline powder, 1 part of diatomaceous earth, 4 parts of quartz sand, 6 parts of carbon black, 12 parts of resin stone powder, 6 parts of triethanolamine and 2 parts of cyclohexanone.

Embodiment 2

[0037] The waterproof material for submarine cables is composed of the following raw materials in parts by weight: 32.5 parts of silicate minerals, 17.5 parts of ethylene-vinyl acetate copolymer, 7 parts of asphalt, 13 parts of nitrile rubber, and 15 parts of m-phenylenediamine , 8 parts of epoxy resin, 6 parts of tourmaline powder, 3.5 parts of diatomaceous earth, 6.5 parts of quartz sand, 9 parts of carbon black, 14 parts of resin stone powder, 7 parts of triethanolamine and 4 parts of cyclohexanone.

Embodiment 3

[0039] The waterproof material for submarine cables is composed of the following raw materials in parts by weight: 35 parts of silicate minerals, 20 parts of ethylene-vinyl acetate copolymer, 9 parts of asphalt, 15 parts of nitrile rubber, and 20 parts of m-phenylenediamine , 9 parts of epoxy resin, 10 parts of tourmaline powder, 6 parts of diatomaceous earth, 9 parts of quartz sand, 12 parts of carbon black, 16 parts of resin stone powder, 8 parts of triethanolamine and 6 parts of cyclohexanone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com