Modified ternary cathode material and preparation method thereof, lithium ion battery

A cathode material and modification technology, which are applied in the field of lithium ion batteries, modified ternary cathode materials and their preparation, can solve the problems of low discharge specific capacity and poor cycle stability, and achieve good cycle stability and good material rate performance. , the effect of reducing side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation of modified ternary cathode material comprises the following steps:

[0046] (1) Weigh 0.1956g In(NO 3 ) 3 Add 20mL of absolute ethanol to the powder for stirring and mixing, the stirring speed is 100 rpm, and the stirring time is 30min, so that In(NO 3 ) 3 The powder is completely dissolved to form a homogeneous solution;

[0047] (2) Add 10.0000g LiNi to the resulting homogeneous solution 0.8 co 0.1 mn 0.1 o 2 The powder was stirred and mixed, the stirring temperature was 30°C, the stirring speed was 800 rpm, and the stirring time was 1h, so that In(NO 3 ) 3 Uniformly adsorbed on LiNi 0.8 co 0.1 mn 0.1 o 2 s surface;

[0048] (3) Evaporate the product obtained in step (2) to dryness at 60°C and a stirring speed of 100 rpm, and then dry it in a blast drying oven at 120°C for 12 hours to obtain a solid powder;

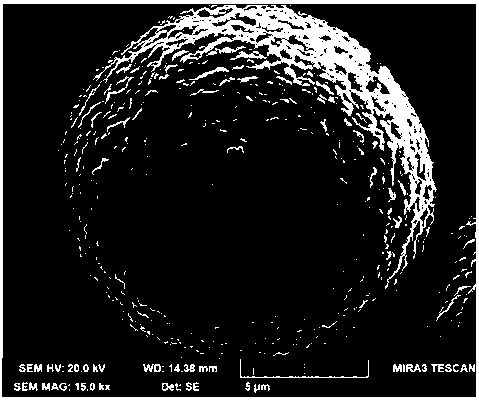

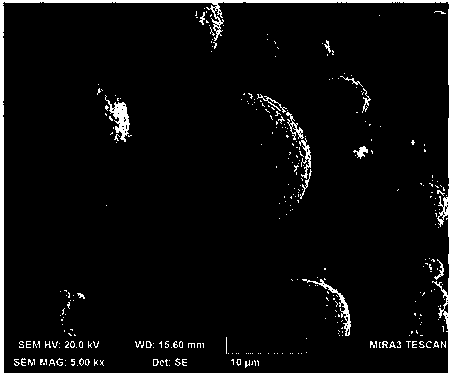

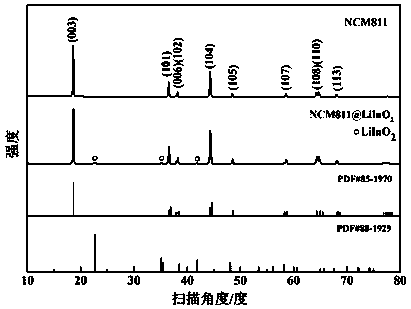

[0049] (4) The obtained solid powder was calcined at 400°C for 12 hours in an air atmosphere to obtain LiNi coated with lithium me...

Embodiment 2

[0051] The preparation of modified ternary cathode material comprises the following steps:

[0052] (1) Weigh 0.7826g In(NO 3 ) 3 Add 40mL of absolute ethanol to the powder for stirring and mixing, the stirring speed is 800 rpm, and the stirring time is 10min, so that In(NO 3 ) 3 The powder is completely dissolved to form a homogeneous solution;

[0053] (2) Add 10.0000g LiNi to the resulting homogeneous solution 0.8 co 0.1 mn 0.1 o 2 The powder was stirred and mixed, the stirring temperature was 40°C, the stirring speed was 100 rpm, and the stirring time was 20h, so that In(NO 3 ) 3 Uniformly adsorbed on LiNi 0.8 co 0.1 mn 0.1 o 2 s surface;

[0054] (3) Evaporate the product obtained in step (2) to dryness at 80°C and a stirring speed of 500 rpm, and then dry it in a blast drying oven at 90°C for 8 hours to obtain a solid powder;

[0055] (4) The obtained solid powder was calcined at 1000°C for 3 hours in an air atmosphere to obtain LiNi coated with lithium met...

Embodiment 3

[0057] The preparation of modified ternary cathode material comprises the following steps:

[0058] (1) Weigh 1.9565g In(NO 3 ) 3 Add 80mL of absolute ethanol to the powder for stirring and mixing, the stirring speed is 500 rpm, and the stirring time is 30min, so that In(NO 3 ) 3 The powder is completely dissolved to form a homogeneous solution;

[0059] (2) Add 10.0000g LiNi to the resulting homogeneous solution 0.8 co 0.1 mn 0.1 o 2 The powder was stirred and mixed, the stirring temperature was 30 ° C, the stirring speed was 500 rpm, and the stirring time was 10 h, so that In(NO 3 ) 3 Uniformly adsorbed on LiNi 0.8 co 0.1 mn 0.1 o 2 s surface;

[0060](3) Evaporate the product obtained in step (2) to dryness at 70°C and a stirring speed of 800 rpm, and then dry it in a blast drying oven at 100°C for 20 hours to obtain a solid powder;

[0061] (4) The obtained solid powder was calcined at 600°C for 6 hours in an air atmosphere to obtain a 10% mass fraction of li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com