Method for enhancing hydrophilic stability of macromolecular film by using metal ions to complex with polyphenol

A metal ion and polymer membrane technology, applied in the field of membrane materials, can solve problems such as weak coating adhesion and coating, and achieve the effects of less additive dosage, good application prospects and lower modification costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

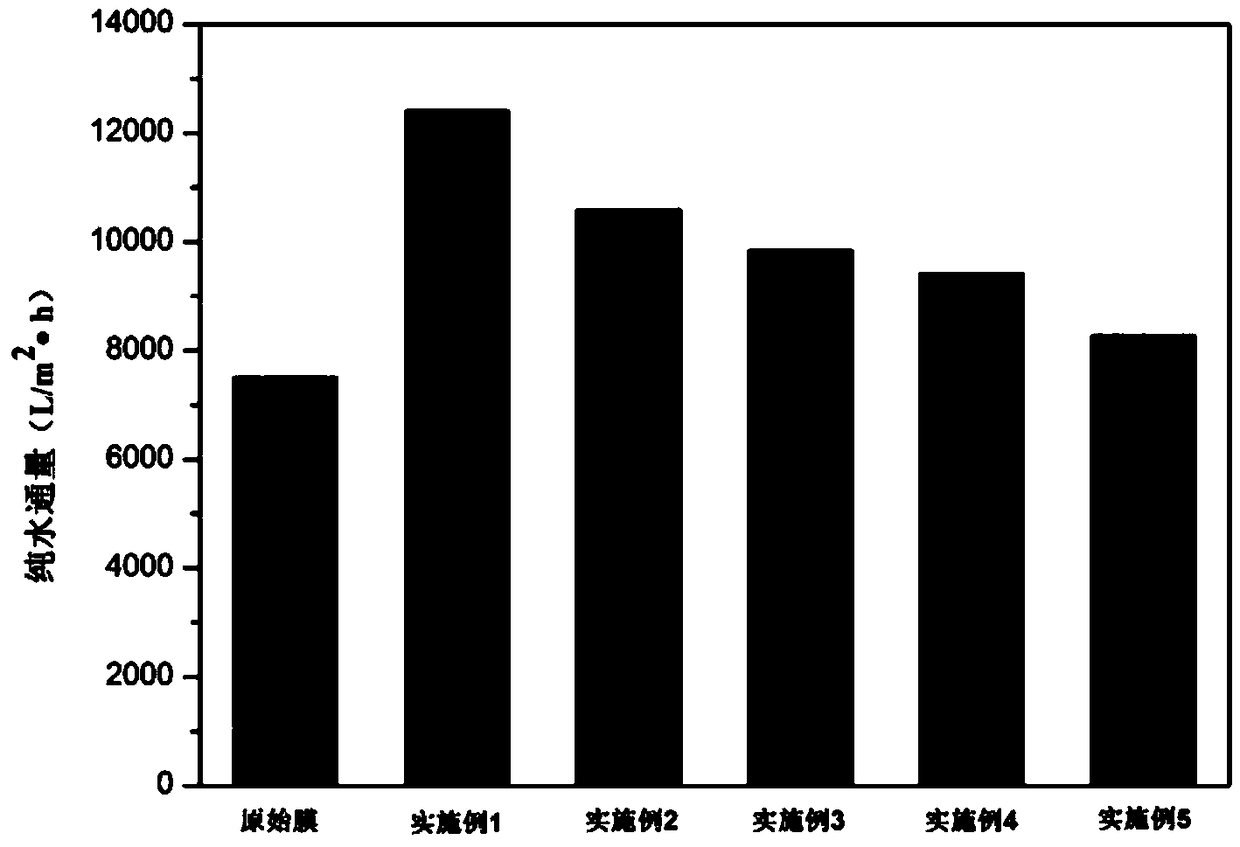

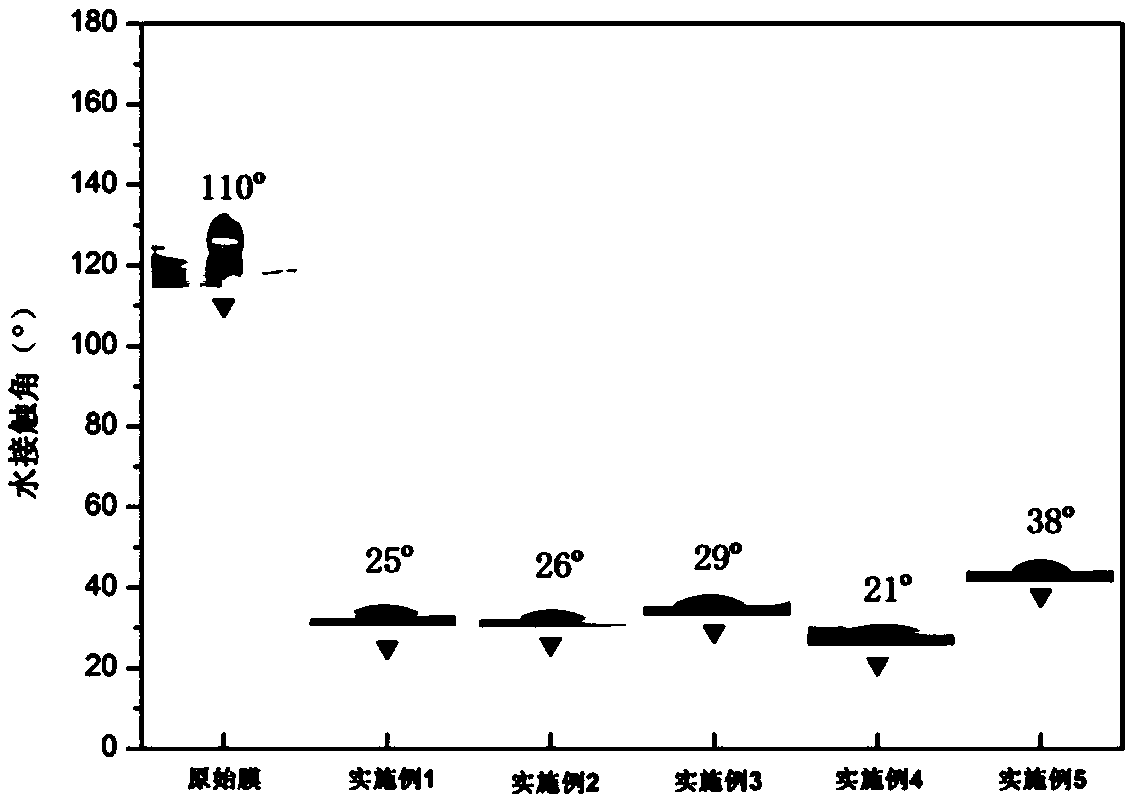

Embodiment 1

[0033] 1) Soak the polyvinylidene fluoride microfiltration membrane with absolute ethanol for 30 minutes at room temperature, then take it out and rinse it with deionized water for 30 minutes;

[0034] 2) Add 20 mg of 3-chloropropyltrimethoxysilane (0.2 g / L) and 80 mg of polyethyleneimine (0.8 g / L) into 100 mL of deionized water, and stir for at least 15 min to obtain modified solution 1. Wash the polyvinylidene fluoride microfiltration membrane treated in step 1 with deionized water, add it to the modified solution 1, and soak it at room temperature for about 10 hours;

[0035] 3) Add 20 mg of tannic acid (0.2 g / L) into 100 mL of prepared tris-hydrochloric acid buffer solution with a pH value of 7.8 to obtain modified solution 2. Wash the polyvinylidene fluoride microfiltration membrane treated in step 2 with deionized water, add it to the modified solution 2, and soak it at room temperature for about 12 hours;

[0036] 4) 20mg of anhydrous ferric chloride (0.2g / L) was dissolv...

Embodiment 2

[0038] 1) Soak the polyvinylidene fluoride microfiltration membrane with isopropanol at room temperature for 30 minutes, then take it out and rinse it with deionized water for 30 minutes;

[0039] 2) Add 20 mg of 3-chloropropyltrimethoxysilane (0.2 g / L) and 80 mg of polyethyleneimine (0.8 g / L) into 100 mL of deionized water, and stir for at least 15 min to obtain modified solution 1. Wash the polyvinylidene fluoride microfiltration membrane treated in step 1 with deionized water, add it to the modified solution 1, and soak it at room temperature for about 10 hours;

[0040] 3) Add 20 mg of tannic acid (0.2 g / L) into 100 mL of prepared tris-hydrochloric acid buffer solution with a pH value of 7.8 to obtain modified solution 2. Wash the polyvinylidene fluoride microfiltration membrane treated in step 2 with deionized water, add it to the modified solution 2, and soak it at room temperature for about 12 hours;

[0041] 4) Dissolve 20mg aluminum sulfate dodecahydrate (0.2g / L) in ...

Embodiment 3

[0043] 1) Soak the polyvinylidene fluoride microfiltration membrane with absolute ethanol for 30 minutes at room temperature, then take it out and rinse it with deionized water for 30 minutes;

[0044] 2) Add 20 mg of 3-chloropropyltrimethoxysilane (0.2 g / L) and 80 mg of polyethyleneimine (0.8 g / L) into 100 mL of deionized water, and stir for at least 15 min to obtain modified solution 1. Wash the polyvinylidene fluoride microfiltration membrane treated in step 1 with deionized water, add it to the modified solution 1, and soak it at room temperature for about 10 hours;

[0045] 3) Add 20 mg of tannic acid (0.2 g / L) into 100 mL of Tris-hydrochloric acid buffer solution with a pH value of 7.8 to obtain modified solution 2. Wash the polyvinylidene fluoride microfiltration membrane treated in step 2 with deionized water, add it to the modified solution 2, and soak it at room temperature for about 12 hours;

[0046] 4) Dissolve 20mg of anhydrous copper sulfate (0.2g / L) in 100mL d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com