Method for preparing nitrogen-doped fluorinated graphene by using graphite fluoride

A technology of fluorinated graphene and fluorinated graphite, which is applied in the direction of graphene and nano-carbon, can solve the problems of weakening the performance of composite materials and low compatibility, and achieves easy operation and control, good compatibility and simple process route Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Weigh the fluorinated graphite and ammonium carbonate at a mass ratio of 1:1, add them to the agate pot (capacity is 100ml), wherein the quality of the fluorinated graphite is 4 grams; add agate beads to the agate pot;

[0019] (2) Fix the agate pot in the ball mill, and grind it for 15 hours during the ball milling process, the ball milling frequency is 540 rpm;

[0020] (3) Add deionized water to the mixture obtained in step 2 to repeatedly wash it, and then carry out suction filtration, vacuum drying and grinding to obtain fluorinated graphene solid powder.

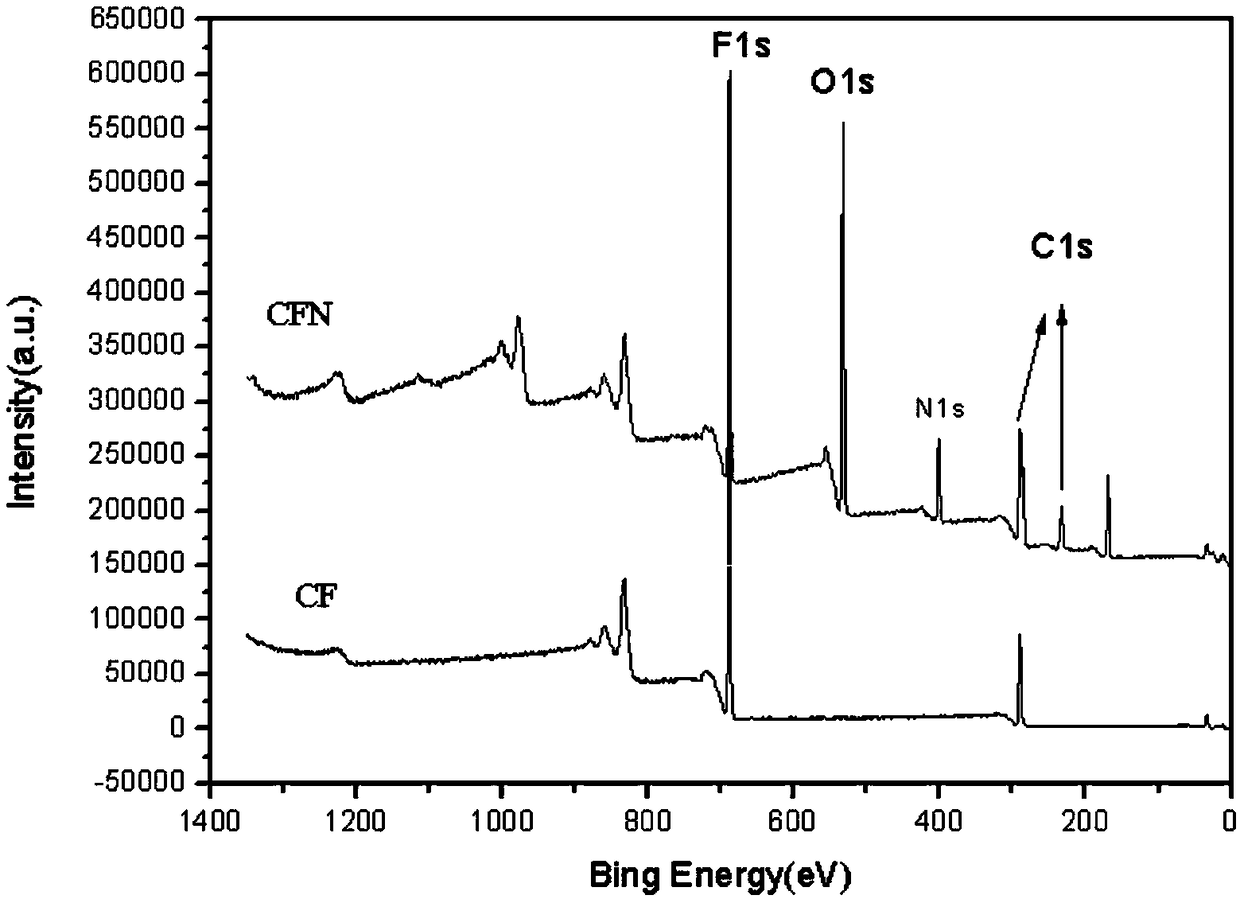

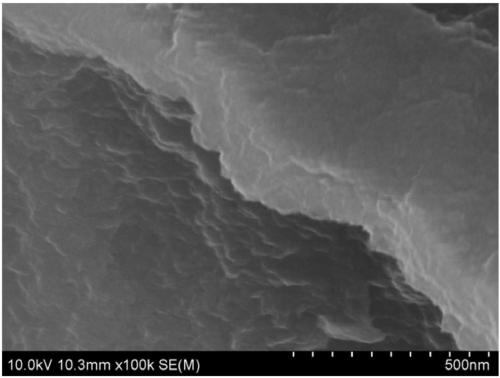

[0021] Through scanning electron microscope observation, it is found that the obtained product is a flake structure, indicating that fluorinated graphite has been successfully exfoliated into fluorinated graphene (as attached figure 1 ). attached figure 2 It is the XPS spectrum of the resulting product. It can be seen from the figure that the original fluorinated graphite (FG) has obvious carbon peaks and...

Embodiment 2

[0023] (1) fluorinated graphite and ammonium carbonate are weighed and mixed respectively, wherein the quality of graphite fluoride is 4 grams, the quality of ammonium carbonate is 8 grams, and the mass ratio is 1:2; add agate beads to the agate pot;

[0024] (2) Fix the agate pot in the ball mill, grind for 20 hours during the ball milling process, the ball milling frequency is 540 rpm;

[0025] (3) Add deionized water to the mixture obtained in step 2 to repeatedly wash it, and then carry out suction filtration, vacuum drying and grinding to obtain fluorinated graphene solid powder.

Embodiment 3

[0027] (1) Mix graphite fluoride with ammonium fluoride, wherein the quality of graphite fluoride is 4 grams, ammonium fluoride is 4 grams, and the mass ratio is 1:1; add agate beads to the agate pot;

[0028] (2) Fix the agate pot in the ball mill, grind for 25 hours during the ball milling process, the ball milling frequency is 600 rpm;

[0029] (3) Add deionized water to the mixture obtained in step 2 to repeatedly wash it, and then carry out suction filtration, vacuum drying and grinding to obtain fluorinated graphene solid powder.

[0030] The morphology of the obtained nitrogen-doped fluorinated graphene is better, and the image 3 The obvious lamellar structure can be clearly seen. attached Figure 4 It is the XPS spectrum of the resulting product. It can be seen from the figure that the original fluorinated graphite (FG) has obvious carbon and fluorine peaks at 294.6eV and 687eV, while nitrogen-doped fluorinated graphene (NG) has more peaks at 400eV. A nitrogen peak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com