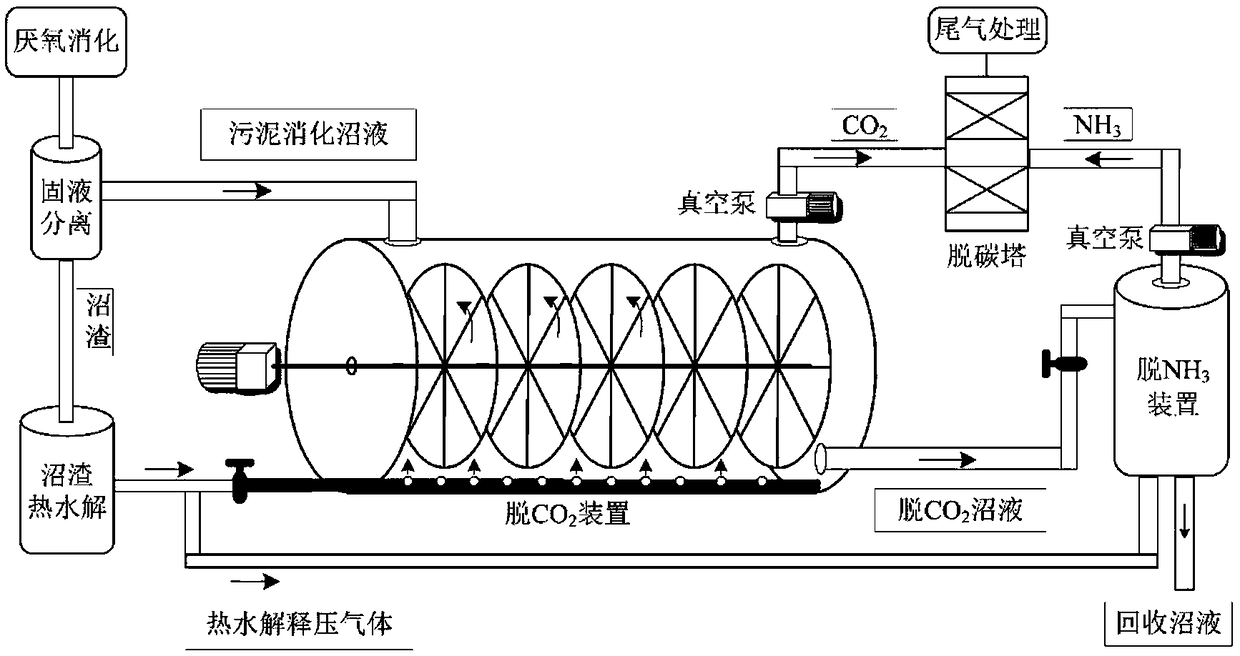

Special CO2 removing deaminizing device and process for sludge digestion biogas slurry

A special device and biogas slurry technology, which is applied in the field of special equipment for CO2 and ammonia removal for sludge digestion and biogas slurry, can solve the problems of complicated process, huge one-time investment cost of equipment, unfavorable large-scale promotion and utilization, etc., and reduce energy consumption cost, meet the effect of green and clean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

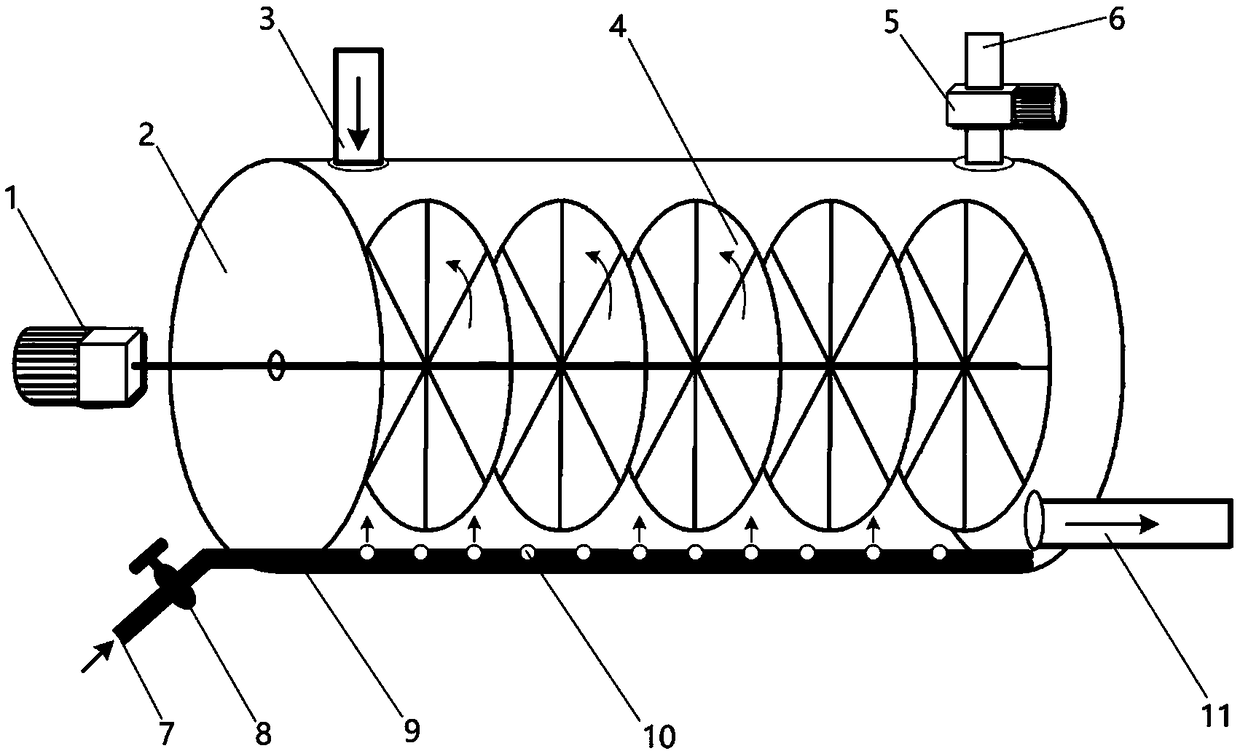

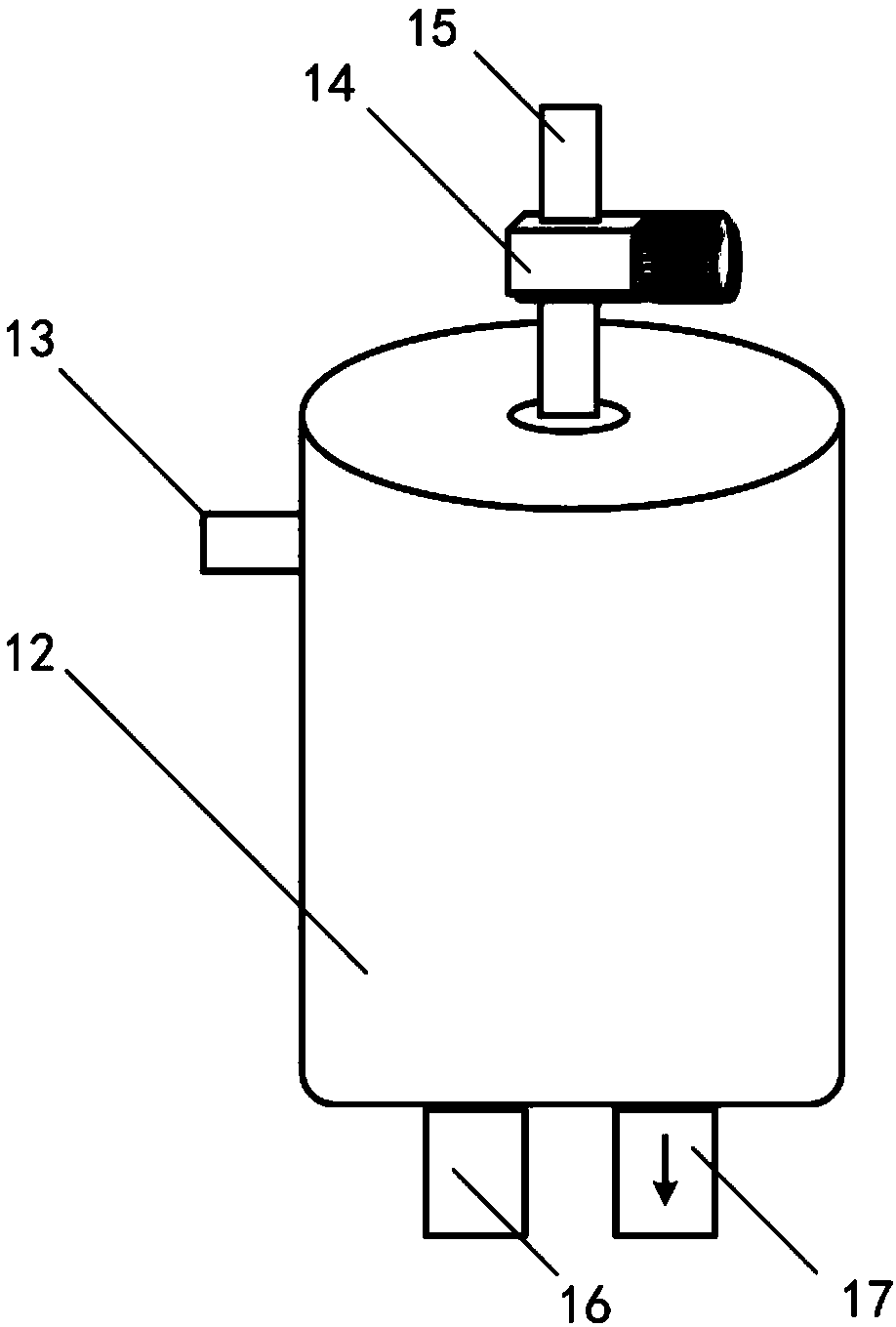

[0041] Send the reflux biogas slurry with high ammonia nitrogen to the CO removal 2 In device 2, make the liquid level of the biogas slurry 2 At 1 / 3 of the height of device 2, the reserved space can increase the CO 2 volatile area. Start the vacuum pump 5 to remove CO 2 The vacuum degree in the device 2 is pumped to -0.08MPa, and then the control valve 8 is opened to introduce the pressure release gas generated during the thermal hydrolysis process of the sludge. A large amount of ammonia contained in the pressure release gas of the thermal hydrolysis will also be absorbed by the biogas slurry. It is dissolved, absorbed and recycled, and the heat carried by the depressurized gas enters the biogas slurry, which is used as a heat source to heat the biogas slurry. Start the circular turntable 4 to stir the biogas slurry, and after the residence time of 10-20 minutes, the CO 2 After the removal operation is over, the pH value of the biogas slurry is around 9.5.

[0042] deCO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com