Acrylamide copolymer and its preparation method and application

A technology of acrylamide copolymer and acrylamide copolymerization, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of increasing the water solubility of the copolymer, increasing the viscosity, unfavorable polymer migration and so on, so as to improve the petroleum The effect of recovery factor, high viscosity and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

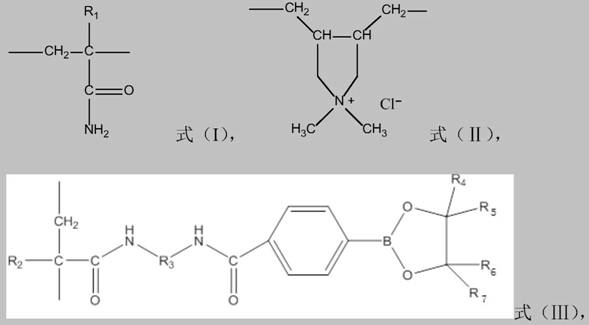

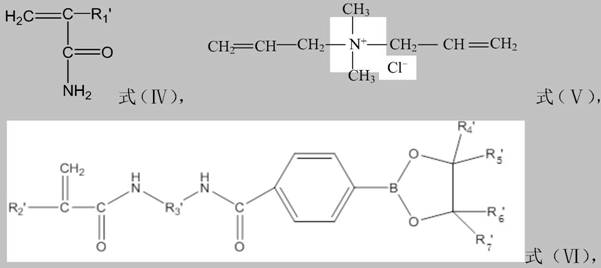

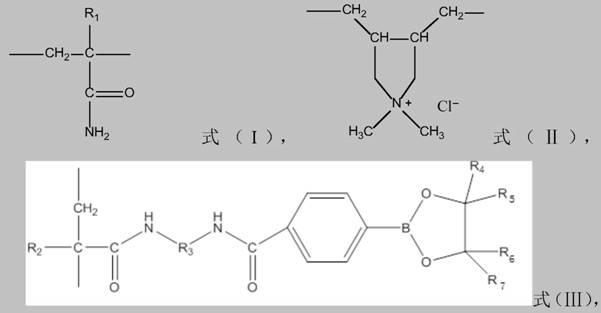

[0046] According to the preparation method of the present invention, as long as the monomer D, the monomer E and the monomer F are copolymerized according to the above ratio, the prepared acrylamide copolymer can achieve the purpose of the present invention to a certain extent . Preferably, the weight ratio of the monomer D, the monomer E and the monomer F is 1:(0.16-0.32):(0.002-0.027).

[0047] According to the preparation method of the present invention, preferably, the polymerization reaction is a random copolymerization reaction.

[0048] According to the preparation method of the present invention, wherein the monomer D having the structure shown in formula (IV) can be an acrylamide-based monomer, examples that can be used include but are not limited to acrylamide, methacrylamide, N,N-di One or more of methacrylamide, N,N-diethylacrylamide, N-isopropylacrylamide, N-methylolacrylamide and N-hydroxyethylacrylamide; preferably, The monomer D is acrylamide or methacrylamid...

preparation example 1

[0077] According to the preparation method of the document "Acs Macro Letters", 2012,1(5):529-532), the structural monomer F shown in formula (VI) is prepared, and its structure is as follows:

[0078]

[0079] That is, in the monomer F of the structure shown in formula (VI), R 2 ' for H, R 3 ' is ethylene, R 4 ', R 5 ', R 6 ' and R 7 ' are each independently a methyl group.

Embodiment 1

[0081] This example is used to illustrate the preparation method of the acrylamide copolymer provided by the present invention.

[0082] (1) Random copolymerization reaction: at room temperature and under stirring conditions, add 190g of acrylamide (AM, monomer D), 50g of dimethyl diallyl ammonium chloride (monomer E) and 2g of The boron-containing monomer (monomer F) and 1000g of deionized water prepared by the above-mentioned Preparation Example 1; after the raw materials are dissolved, add sodium hydroxide to the aqueous solution to adjust the pH of the aqueous solution to 7.5; then feed nitrogen into the aqueous solution to remove oxygen After 30 minutes, seal the beaker to form an inert atmosphere; then add 0.01 g of ammonium persulfate and 0.01 g of sodium bisulfite to the aqueous solution as a redox initiation system, and then react at normal pressure and 15°C at a constant temperature (temperature control with frozen brine) for 7 Hour, obtain colloidal polymer solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com