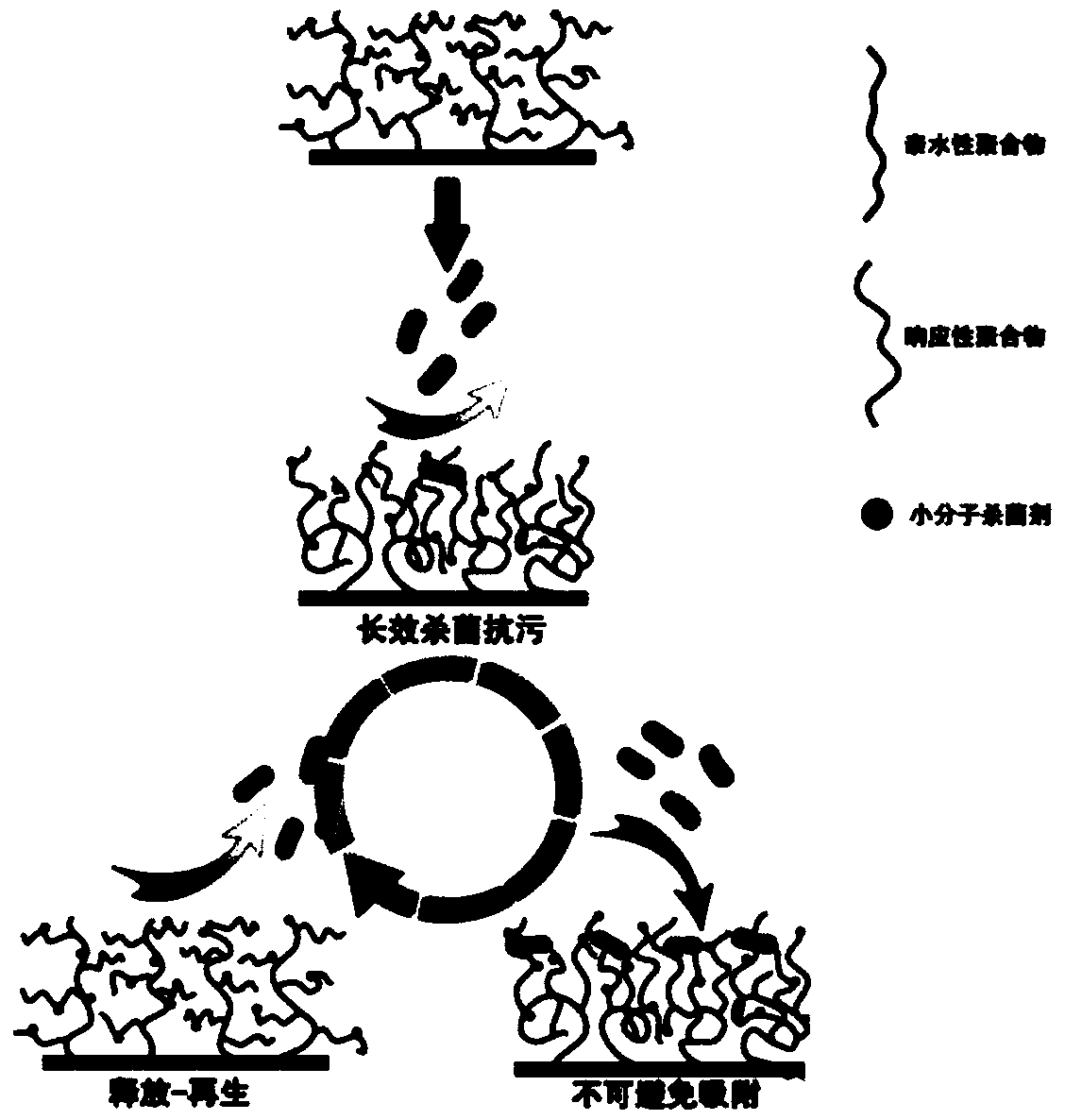

Preparation method of antimicrobial polymer brush with triple functions of anti-fouling, sterilization and release

A technology of polymer brush and function, which is applied in the field of antibacterial polymer brush and its preparation, can solve the problems of single function and narrow application range, and achieve the effect of good safety, simple method and widening application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

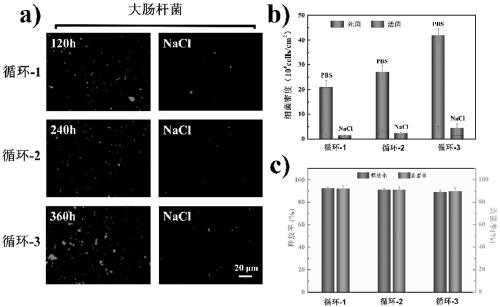

Examples

Embodiment 1

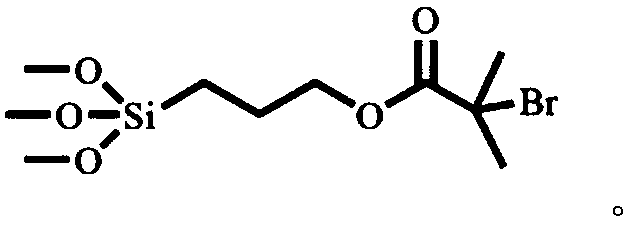

[0051] (1) Treat the silicon wafer with an oxygen plasma surface processor for 2 minutes, then place the processed silicon wafer in a toluene solution with (2-bromo-2-methylpropionyloxypropyl)trimethoxysilane dissolved in it Soak for 24h;

[0052] (2) Take 2 clean test tubes, numbered test tube 1 and test tube 2, add 0.35g DVBAPS, 1.5mL trifluoroethanol, 1.5mL deionized water, 7μL ligand Me to test tube 1. 6 TREN; add 7mg CuBr and 2 pieces of silicon wafers obtained in step (1) to test tube 2 in turn; both test tubes are deoxygenated and filled with nitrogen 3 times, and then nitrogen is blown for 30 minutes, then the liquid in test tube 1 is drawn out to test tube 2 with a syringe In the process, deoxygenate and fill nitrogen again 3 times, and react test tube 2 in a constant temperature shaking box at 25°C for 24 hours. After the reaction is completed, it is ultrasonically cleaned twice in brine and deionized water, and dried with nitrogen to obtain a poly DVBAPS brush;

[0053] ...

Embodiment 2

[0060] (1) Treat the silicon wafer with an oxygen plasma surface processor for 2 minutes, then place the processed silicon wafer in a toluene solution with (2-bromo-2-methylpropionyloxypropyl)trimethoxysilane dissolved in it Soak for 24h;

[0061] (2) Take 2 clean test tubes, number test tube 1 and test tube 2. Add 0.5g NIPAM, 1.5mL methanol, 1.5mL deionized water, 33μL ligand PMDETA to test tube 1; add 13mg CuBr and 2 tablets to test tube 2 in sequence The silicon wafer obtained in step (1); both test tubes are deaerated and filled with nitrogen 3 times, and after blowing nitrogen for 30 minutes, the liquid in test tube 1 is drawn into test tube 2 with a syringe, and the test tube is deaerated and filled with nitrogen 3 times again. 2 React in a constant temperature shaking box at 25°C for 12 hours. After the reaction is completed, perform ultrasonic cleaning twice in methanol, ethanol, and deionized water, and blow dry with nitrogen to obtain a polyNIPAM brush;

[0062] (3) Take...

Embodiment 3

[0065] (1) Treat the silicon wafer with an oxygen plasma surface processor for 2 minutes, then place the processed silicon wafer in a toluene solution with (2-bromo-2-methylpropionyloxypropyl)trimethoxysilane dissolved in it Soak for 24h;

[0066] (2) Take 2 clean test tubes, number test tube 1 and test tube 2, add 0.54gMAA and 3.0mL deionized water to test tube 1; add 43mg ligand Bpy and 11mg CuBr / CuBr to test tube 2 2 (m:m=1:1) mixture and 2 pieces of silicon wafers obtained in step (1); both test tubes are deoxygenated and filled with nitrogen 3 times, and then nitrogen is blown for 30 minutes, and then the liquid in test tube 1 is drawn out with a syringe Into test tube 2, deoxygenate and nitrogenate again 3 times. Test tube 2 was reacted in a constant temperature shaking box at 25°C for 12 hours. After the reaction was completed, it was ultrasonically cleaned twice in ethanol and deionized water, and dried with nitrogen to obtain a polyMAA brush;

[0067] (3) Take 2 clean test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com