Method for preparing enhanced and toughened L-polylactide composite membrane based on wool keratin cortex cell

A technology of L-polylactic acid and wool keratin, which is applied in the field of polymer material preparation, can solve problems such as the difficulty of using L-lactic acid film to toughen, and achieve the effects of strong directional degradation, efficient separation, and improved brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

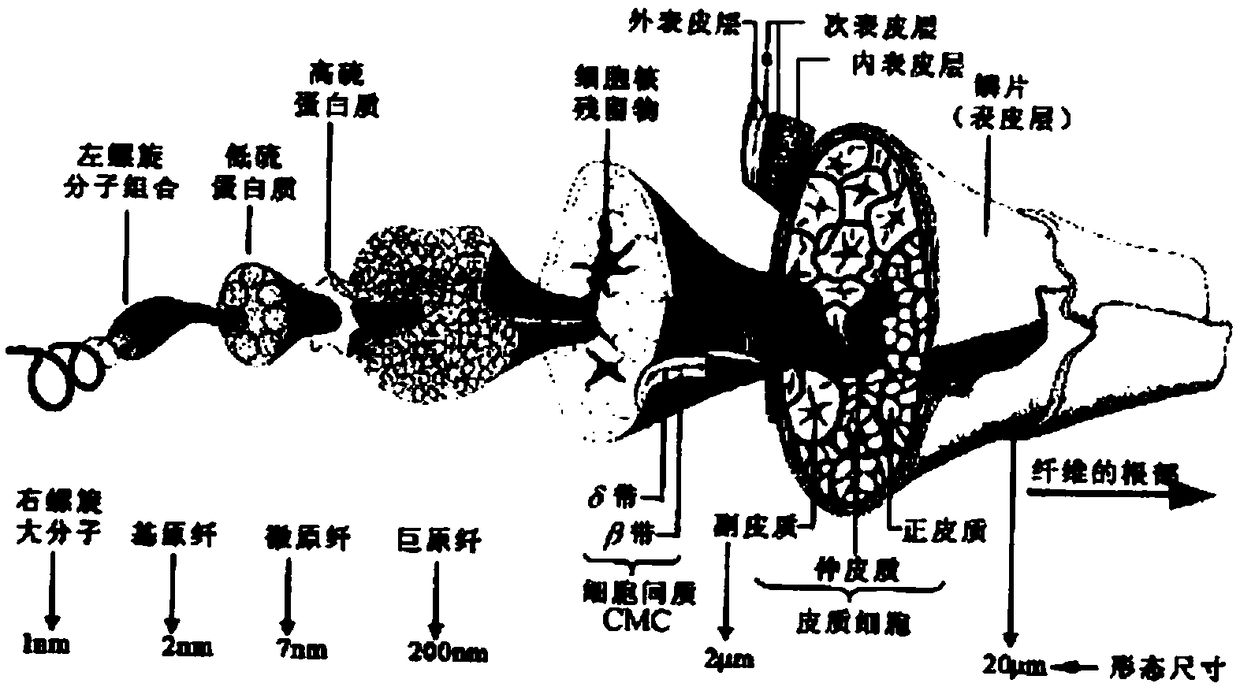

[0056] Embodiment 1: a kind of preparation method of wool keratin cortex cell, the steps are as follows:

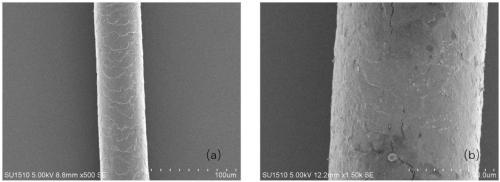

[0057] Step 1. Use calcium hypochlorite / hydrogen peroxide to remove the wool surface scale layer:

[0058] (1) Soak the waste rough wool in water at 25°C, the solid-to-liquid ratio is 1:25, soak the wool thoroughly, and add calcium hypochlorite Ca(ClO) with an active chlorine content of 70% 2 ·3H 2 O, standing for 5 minutes to obtain system A; wherein the amount of calcium hypochlorite added is 5% of the wool quality.

[0059] (2) slowly adding mass fraction in system A is 30% hydrogen peroxide, sodium pyrophosphate as peroxide stabilizer, ethylenediaminetetraacetic acid as peroxide chelating agent to form system B; Treat under constant temperature conditions for 20 minutes to make the wool react with hypochlorite and peroxide; wherein, based on the volume of the solution in system A, the amount of hydrogen peroxide with a mass fraction of 30% is 14ml / L, and the coke T...

Embodiment 2

[0069] Embodiment 2: a kind of preparation method of wool keratin cortex cell, the steps are as follows:

[0070] Step 1. Use calcium hypochlorite / hydrogen peroxide to remove the wool surface scale layer:

[0071] (1) Soak the waste fine wool in water at 20°C, the solid-to-liquid ratio is 1:20, soak the wool thoroughly, and add calcium hypochlorite Ca(ClO) with an active chlorine content of 70% 2 ·3H 2 O, stand still for 5 minutes to obtain system A; wherein the added amount of calcium hypochlorite is 3% of the wool quality.

[0072] (2) Slowly add hydrogen peroxide, sodium pyrophosphate as a peroxide stabilizer, and ethylenediaminetetraacetic acid as a peroxide chelating agent in system A to form system B; Treat under constant temperature conditions for 20 minutes to make wool react with hypochlorite and peroxide; wherein, based on the volume of the solution in system A, the mass fraction of 30% hydrogen peroxide is added in an amount of 10ml / L, The added amount of sodium ...

Embodiment 3

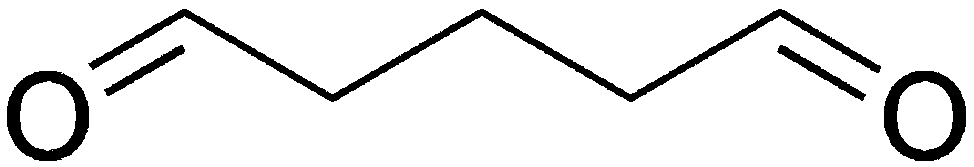

[0093] Embodiment 3: A method for preparing porous materials based on wool keratin cortex cells, the specific steps are as follows:

[0094] Step 1, using wool keratin cortex cells as raw materials, preparing an aqueous suspension of cortex cells with a mass percentage of 5%;

[0095] Step 2: Add glutaraldehyde to the aqueous suspension of cortical cells, the quality of glutaraldehyde in the mixed solution is respectively 0.15%, 0.8% and 1.5% of the mass of wool keratin cortical cells, and magnetically stir for 10 minutes to obtain three homogeneous milky white suspension;

[0096] Step 3. Quickly freeze the milky white suspension at -40°C for 10 hours, and then vacuum freeze-dry for 36 hours;

[0097] Step 4: Put the vacuum freeze-dried sample in an oven at 180° C. for 2 hours, and cross-link keratin with glutaraldehyde to obtain three kinds of porous materials of wool cortex cells.

[0098] Carry out following analysis for the experimental result of embodiment 3:

[0099]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com