Antibacterial anti-mold water drainage PVC (Polyvinyl Chloride) tube and production method thereof

A PVC pipe, antibacterial and anti-mildew technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of poor adhesion of antibacterial coatings, easy product delamination, failure, etc. Improve the effect of long-term effect and dispersion performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

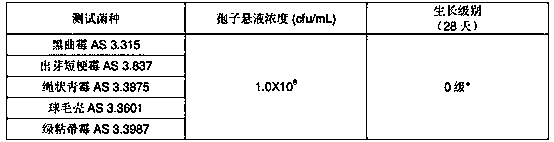

Examples

Embodiment 1

[0023] A kind of antibacterial and mildew-proof drainage PVC pipe material of the present embodiment comprises the antibacterial and mildew-proof layer as the inner layer and the PVC composite material layer as the outer layer; the antibacterial and mildew-proof layer is nano metal ion / PVC composite material, comprises the following parts by weight Components: 100 parts of PVC, 0.5 parts of nano metal ions, 3.5 parts of stabilizer, 10 parts of chlorinated polyethylene, 0.5 parts of stearic acid, 1 part of lead stearate, 0.2 parts of polyethylene wax, 0.5 parts of processing aids, 0.5 part of composite coupling agent, 1 part of macromolecule loading, and 0.5 part of macromolecular compatibilizer.

[0024] The nano-metal ions used in the antibacterial and mildew-proof layer are nano-silver ions and nano-zinc ions.

[0025] The macromolecular load used in the antibacterial and antifungal layer is a zeolite imidazolate skeleton structure material.

[0026] The macromolecule compa...

Embodiment 2

[0031] A kind of antibacterial and mildew-proof drainage PVC pipe material of the present embodiment comprises the antibacterial and mildew-proof layer as the inner layer and the PVC composite material layer as the outer layer; the antibacterial and mildew-proof layer is nano metal ion / PVC composite material, comprises the following parts by weight Each component: 100 parts of PVC, 1 part of nano metal ion, 4 parts of stabilizer, 8 parts of chlorinated polyethylene, 1 part of stearic acid, 3 parts of lead stearate, 0.5 part of polyethylene wax, 1 part of processing aid, 1 part of composite coupling agent, 2 parts of macromolecular loading, 2 parts of macromolecular compatibilizer

[0032] The nano-metal ions used in the antibacterial and mildew-proof layer are nano-gold ions and nano-copper ions.

[0033] The macromolecular load used in the antibacterial and antifungal layer is a zeolite imidazolate skeleton structure material.

[0034] The macromolecule compatibilizer used i...

Embodiment 3

[0039] An antibacterial and mildew-proof drainage PVC pipe, comprising an antibacterial and mildew-proof layer as an inner layer and a PVC composite material layer as an outer layer; the inner antibacterial and mildew-proof layer is a nanometer metal ion / PVC composite material, including each group of the following parts by weight Divide: 100 parts of PVC, 2 parts of nano-metal ions, 5.5 parts of stabilizer, 12 parts of chlorinated polyethylene, 1.5 parts of stearic acid, 3 parts of lead stearate, 0.8 parts of polyethylene wax, 2 parts of processing aid, compound 1 part of coupling agent, 5 parts of macromolecule loading, 4 parts of macromolecular compatibilizer.

[0040] The nano-metal ions used in the antibacterial and mildew-proof layer are nano-silver ions, nano-copper ions, and nano-zinc ions.

[0041] The macromolecular load used in the antibacterial and antifungal layer is a zeolite imidazolate skeleton structure material.

[0042] The macromolecule compatibilizer used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com