Energy-saving closed heat pump sludge drying and dehumidifying system and technology

A sludge and heat pump technology, applied in drying, heat pumps, dryers, etc., can solve the problems of high energy consumption, environmental pollution, and high operating costs, and achieve the goal of reducing energy consumption, not affecting heat balance, and increasing dehumidification capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

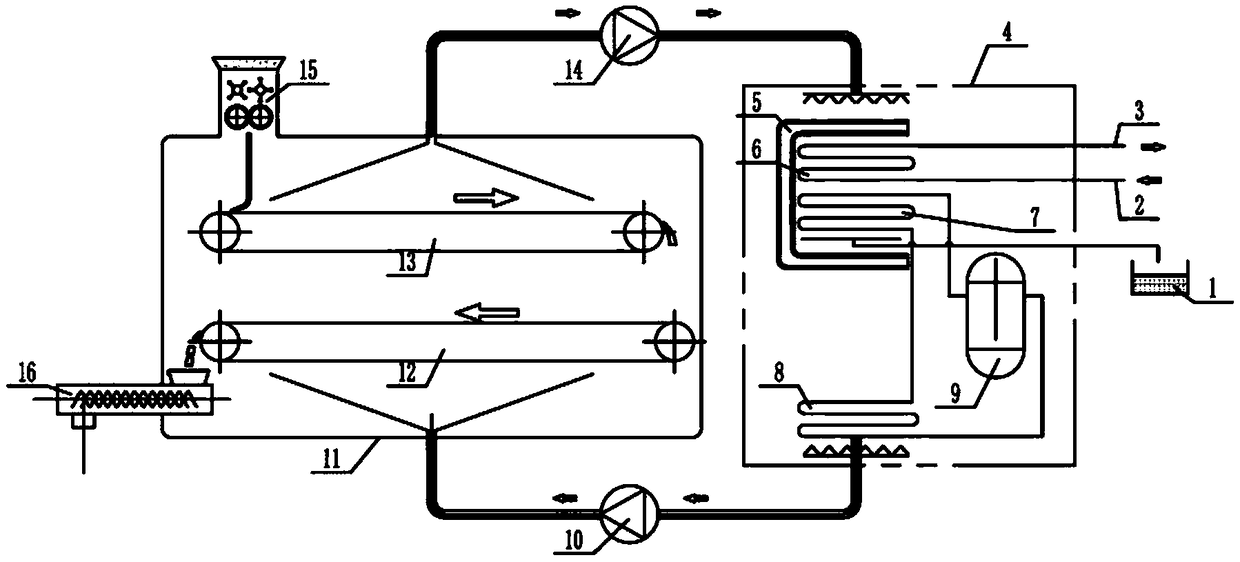

[0031] Such as figure 1 Shown is a closed heat pump sludge drying and dehumidification equipment. The wet sludge exchanges heat with dry and hot air in the drying chamber 11. The wet sludge becomes dry sludge and the dry and hot air becomes humid air.

[0032] Further, the wet sludge molding equipment 15 squeezes the wet sludge into strips and evenly spreads it on the first layer of sludge flat net 12, and moves with the belt 12 of the first layer of sludge flat net 12, The wet sludge exchanges heat and moisture with the surrounding dry and hot air, the water on the sludge surface evaporates, and the water inside the wet sludge penetrates to the surface of the wet sludge. At this time, the surface humidity of the wet sludge in contact with the air is higher than that of the wet sludge The humidity inside the mud is low, and the sludge enters the second layer of sludge flat net 13 through the end of the first layer of sludge flat net 12, because the first layer of sludge flat n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com