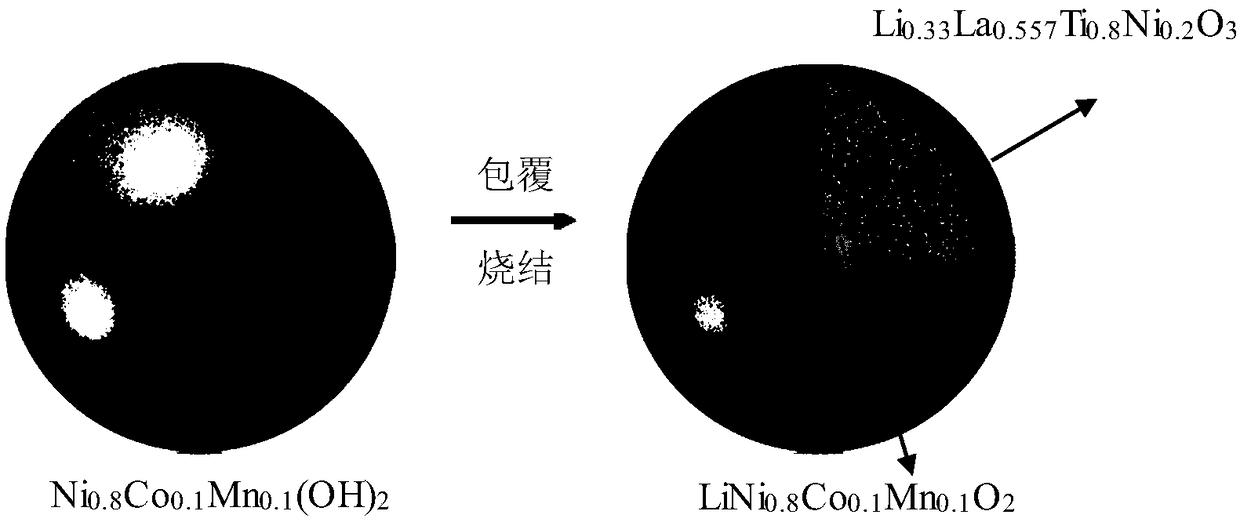

A method for coating a perovskite structural material on that surface of a positive electrode particle

A perovskite structure and surface coating technology, applied in structural parts, battery electrodes, electrical components, etc., can solve problems such as low electronic conductance, unusable positive electrode materials, and inability to export/import electrons from positive particles, and achieve improved Electronic conductivity, improved cycle stability, lower cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of LiNi 0.8 co 0.1 mn 0.1 o 2 ~ Li 0.33 La 0.557 Ti 0.9 Ni 0.1 o 3 The positive electrode material with core-shell structure, the ratio of substrate to coating material is 30:1.

[0025] The preparation method is as follows:

[0026] (1) According to the composition of the coating layer, prepare a solution with a concentration of 0.1mol / L, in which La(NO 3 ) 3 ·6H 2 O is 0.0557mol / L, NiSO 4 ·6H 2 O is 0.01mol / L, Ti(SO 4 ) 2 It is 0.09mol / L. Dissolve the above salt in deionized water, stir well, add H 2 SO 4 , adjust its pH value to about 2 to obtain a mixed salt solution. Prepare 0.5mol / L ammonia water and 1mol / L NaOH solution, and stir evenly;

[0027] (2) Configure the dispersion of the matrix precursor particles, and the matrix precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 The particles are added to deionized water, containing 0.2mol of matrix particles per liter, and stirred with a magnetic stirrer at a stirring speed of 1000rpm to form a ...

Embodiment 2

[0033] Preparation of LiNi 0.9 co 0.05 mn 0.05 o 2 ~ Li 0.33 La 0.557 Ti 0.8 co 0.2 o 3 Core-shell structure positive electrode material, the ratio of substrate to cladding material is 40:1.

[0034] The preparation method is as follows:

[0035] (1) According to the composition of the coating layer, prepare a solution with a concentration of 0.100mol / L, where La(NO 3 ) 3 ·6H 2 O is 0.0557mol / L, CoSO 4 ·7H 2 O is 0.020mol / L, Ti(SO 4 ) 2 It is 0.080mol / L. Stir it well, add dropwise H 2 SO 4 , adjust the pH value to about 2 to obtain a mixed salt solution. Prepare 0.5mol / L ammonia water and 1mol / L NaOH solution, and stir evenly;

[0036] (2) Configure the dispersion of the matrix precursor particles, and the matrix precursor Ni 0.9 co 0.05 mn 0.05 (OH) 2 The particles are added to deionized water, containing 0.2mol of matrix particles per liter, and stirred with a magnetic stirrer at a stirring speed of 1000rpm to form a uniform suspension;

[0037] (3) T...

Embodiment 3

[0042] Preparation of Li[Li 0.2 Ni 0.13 co 0.13 mn 0.54 ]O 2 ~ Li 0.33 La 0.557 Ti 0.8 Ni 0.2 o 3 Core-shell structure positive electrode material, the molar ratio of substrate and cladding layer is 50:1.

[0043] The preparation method is as follows:

[0044] (1) According to the composition of the coating layer, prepare a solution with a concentration of 0.1mol / L, in which La(NO 3 ) 3 ·6H 2 O is 0.0557mol / L, Ni(SO 4 ) 2 ·6H 2 O is 0.020mol / L, Ti(SO 4 ) 2 It is 0.08mol / L. Stir it well, add dropwise H 2 SO 4 , adjust the pH value to about 2 to obtain a mixed salt solution. Prepare 0.5mol / L ammonia water and 1mol / L NaOH solution, and stir evenly;

[0045] (2) Configure the dispersion of the matrix precursor particles, and the matrix precursor Ni 1 / 6 co 1 / 6 mn 4 / 6 CO 3 The particles are added to deionized water, containing 0.2mol of matrix particles per liter, and stirred with a magnetic stirrer at a stirring speed of 1000rpm to form a uniform suspension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com