Method for rapidly synthetizing Cu2Se-based thermoelectric material through autocatalysis at low temperature

A thermoelectric material and self-catalysis technology, which can be used in binary selenium/tellurium compounds, photovoltaic power generation, metal selenide/tellurium compounds, etc. The effect of precise composition, optimized thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A self-catalyzed low-temperature rapid synthesis of Cu 2 The method for Se-based thermoelectric material, comprises the steps:

[0031] 1) Using Cu powder and Se powder as raw materials, according to the stoichiometric ratio of Cu 2(1+x) Se, x = 3% weighed, a total of 7g;

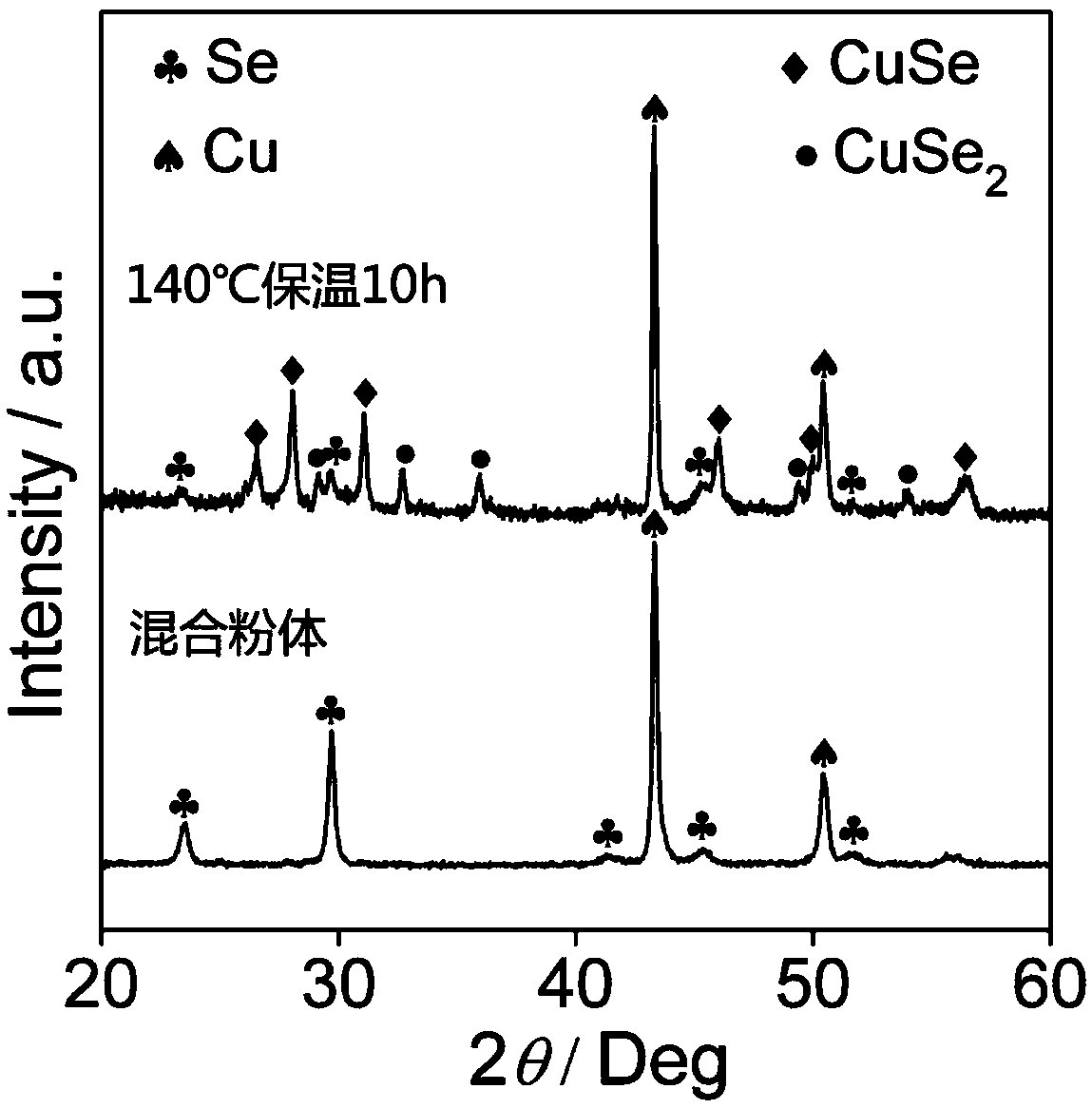

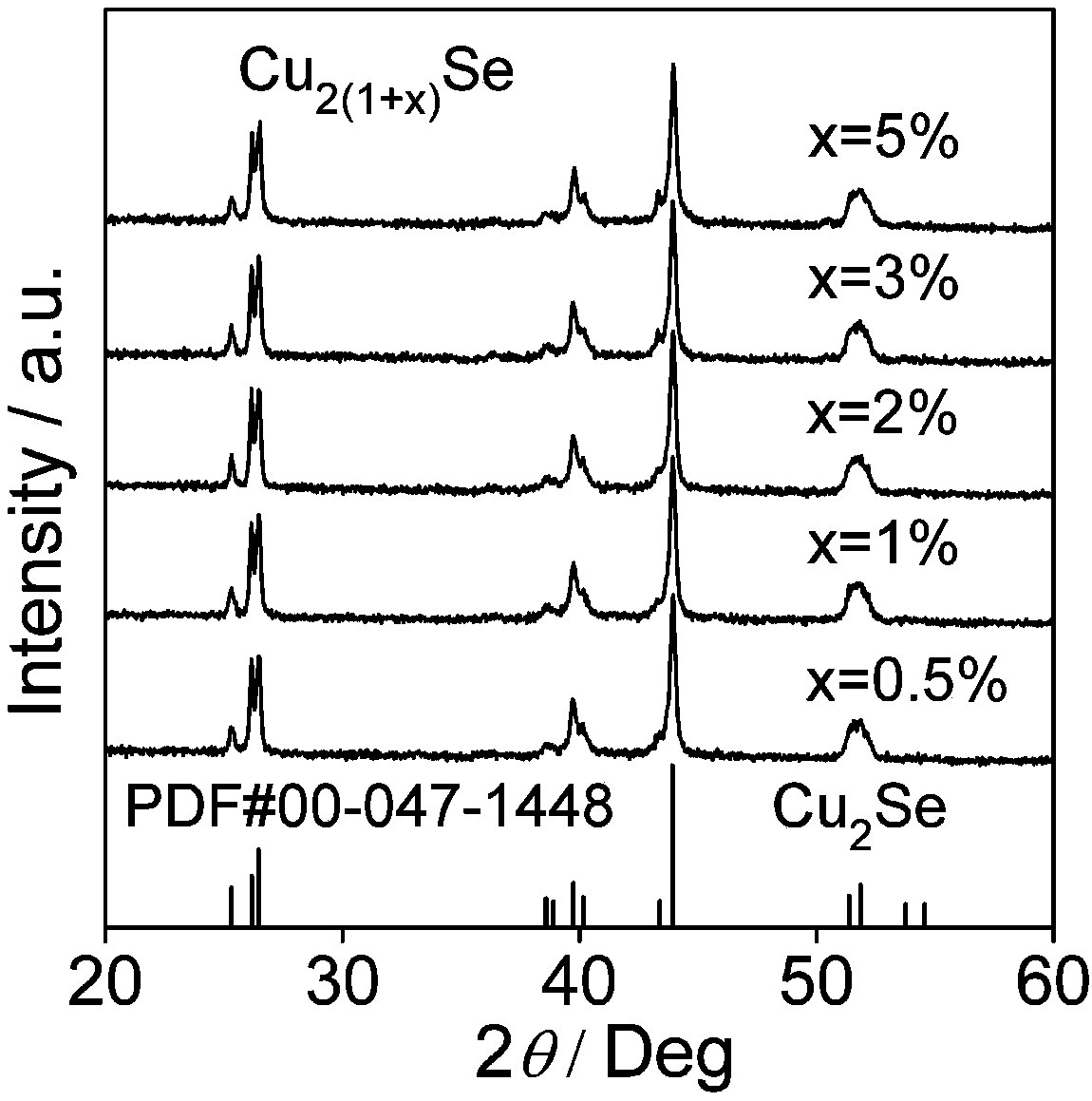

[0032] 2) Mix the weighed raw materials evenly in an agate mortar to obtain the mixed raw materials, then put them into a steel mold, use a pressure of 6 MPa on the tablet press and keep the pressure for 5 minutes to make a Φ12mm green body, and then put the green body into a test tube , and then the test tube was placed in an oil bath at 130°C for 3 minutes, and it was found that the green body turned from dark brown to black, and the green body was taken out for XRD analysis (see figure 2 ), the resulting XRD pattern and Cu 2 The Se standard card fits, indicating the formation of Cu 2 Se single-phase compound, indicating that a small amount of Cu excess can catalyze the synthesis of Cu from Cu...

Embodiment 2~5

[0037] A self-catalyzed low-temperature rapid synthesis of Cu 2 The method for Se-based thermoelectric material, comprises the steps:

[0038] 1) Using Cu powder and Se powder as raw materials, according to the stoichiometric ratio of Cu 2(1+x) Se, x are respectively 0.5%, 1%, 2%, 5% to weigh, respectively 7g;

[0039] 2) Mix the weighed raw materials in an agate mortar evenly to obtain the mixed raw materials, then put them into a steel mold, use a pressure of 6 MPa on the tablet press and keep the pressure for 5 minutes to make a Φ12mm green body, and then put the green body into In the test tube, the test tube was placed in an oil bath at a temperature of 130°C for 3 minutes. It was found that the green body turned from dark brown to black, and the green body was taken out for XRD analysis (see figure 2), the resulting XRD patterns are all consistent with Cu 2 The Se standard cards match, indicating that Cu was generated 2 Se single-phase compound;

[0040] 3) with st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com