A high-strength ultra-light composite lithium band and a preparation method thereof are provided

A complex lithium, high-strength technology, applied in electrode carriers/current collectors, electrical components, electrochemical generators, etc., can solve the problems of low weight energy density of batteries, low reliability of tab connections, etc., to prevent falling off, The effect of good electrical conductivity and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

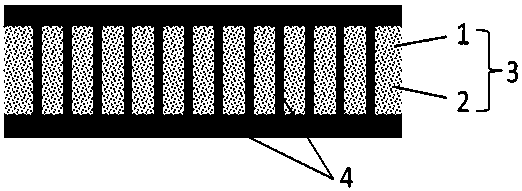

[0012] Specific embodiment one: what this embodiment records is a kind of high-strength ultra-light composite lithium ribbon, described composite lithium ribbon comprises conductive skeleton and metal lithium or lithium alloy 4 attached on the conductive skeleton; Described conductive skeleton is The conductive powder material 1 is uniformly dispersed in the polymer 2 to form a porous film 3 .

specific Embodiment approach 2

[0013] Embodiment 2: The high-strength ultra-light composite lithium ribbon described in Embodiment 1, the thickness of the conductive skeleton is 1-100 μm, and the porosity is 0.01-80%.

specific Embodiment approach 3

[0014] Specific embodiment three: a kind of high-strength ultra-light composite lithium strip described in specific embodiment one, the described conductive powder material is carbon black, carbon nanotube, graphene, carbon fiber, nano-copper powder, nano-aluminum powder, Nano-nickel powder, nano-silver powder, phthalocyanine blue, zinc oxide or tin dioxide doped with Sb.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com