Chalcogenide composite cathode material, an all-solid-state lithium battery thereof and a preparation method thereof

A composite positive electrode material and lithium battery technology, which is applied in the manufacture of electrolyte batteries, positive electrodes, secondary batteries, etc., can solve the problems of limited energy density improvement of all-solid-state lithium batteries, poor cycle performance of all-solid-state lithium batteries, and low active material loading capacity and other issues, to achieve the effect of improving cycle performance and capacity retention rate, simple structure, and high output energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

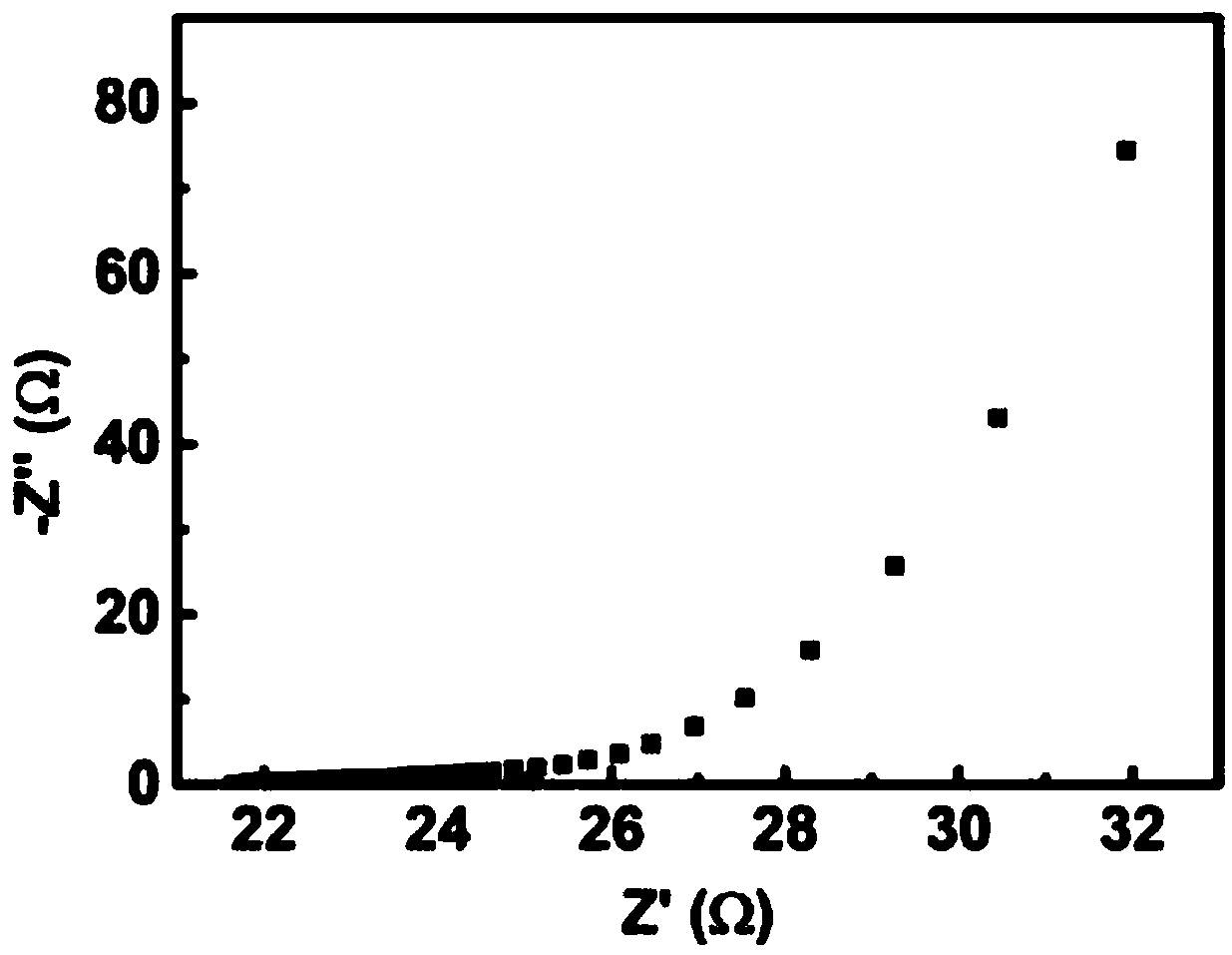

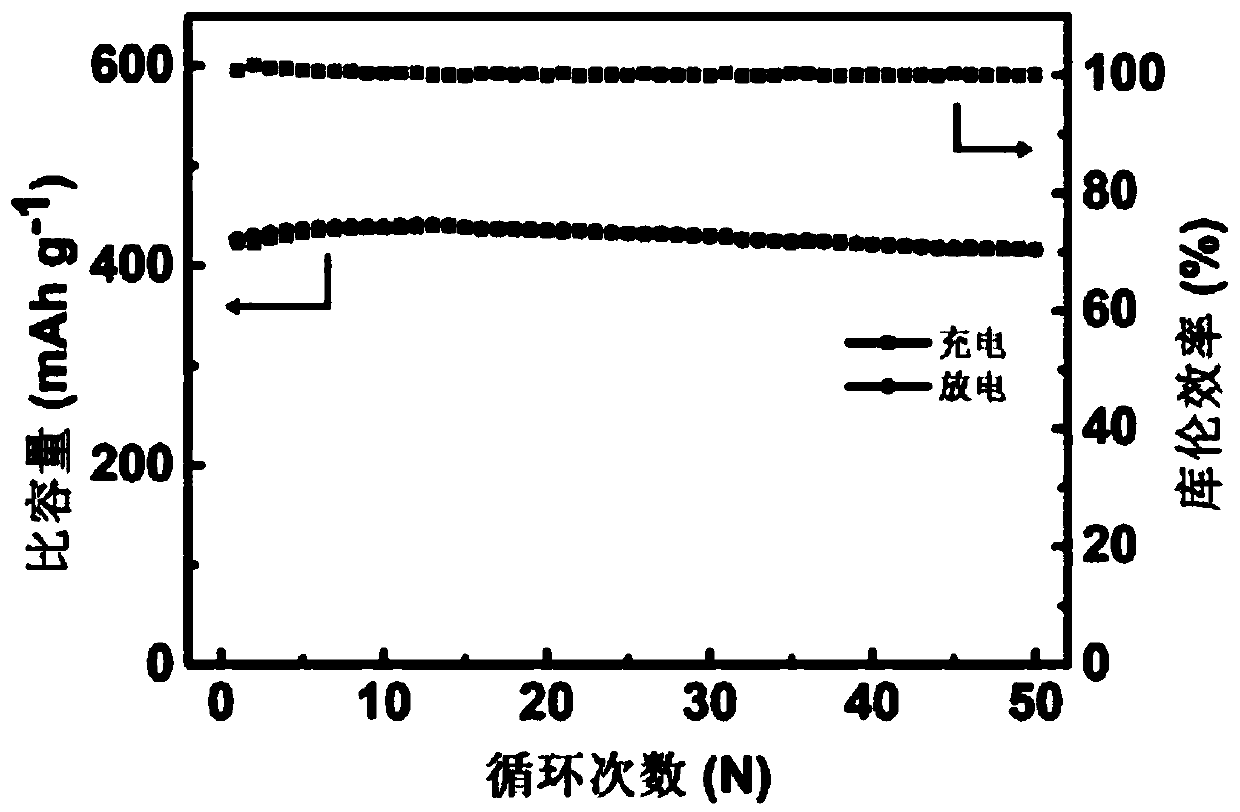

[0036] This example uses Li 6 P.S. 5 Cl sulfide electrolyte, which not only serves as the positive electrode active material, but also serves as the material of the solid electrolyte layer. Commercial multi-walled carbon nanotubes are used as conductive carbon materials, and lithium indium alloys are used as negative electrode materials to assemble all-solid lithium-ion batteries. The specific steps are as follows:

[0037] (1) will P 2 S 5 (Aladding 99%), Li 2 S (Alfa 99.9%) and LiCl (Aladding 99.99%) were ball milled for 1 hour at a speed of 100 rpm; then the mixture was sealed and heat-treated at 550°C for 3 hours to obtain Li 6 P.S. 5 Cl sulfide electrolyte.

[0038] (2) will Li 6 P.S. 5 Cl sulfide electrolyte and multi-walled carbon nanotubes (mass ratio 86:14) were mixed by dry ball milling at a speed of 300rpm for 1h to complete the preparation of the composite cathode powder.

[0039] (3) Weigh 70mg Li 6 P.S. 5Cl sulfide electrolyte powder, in a mold with a ...

Embodiment 2

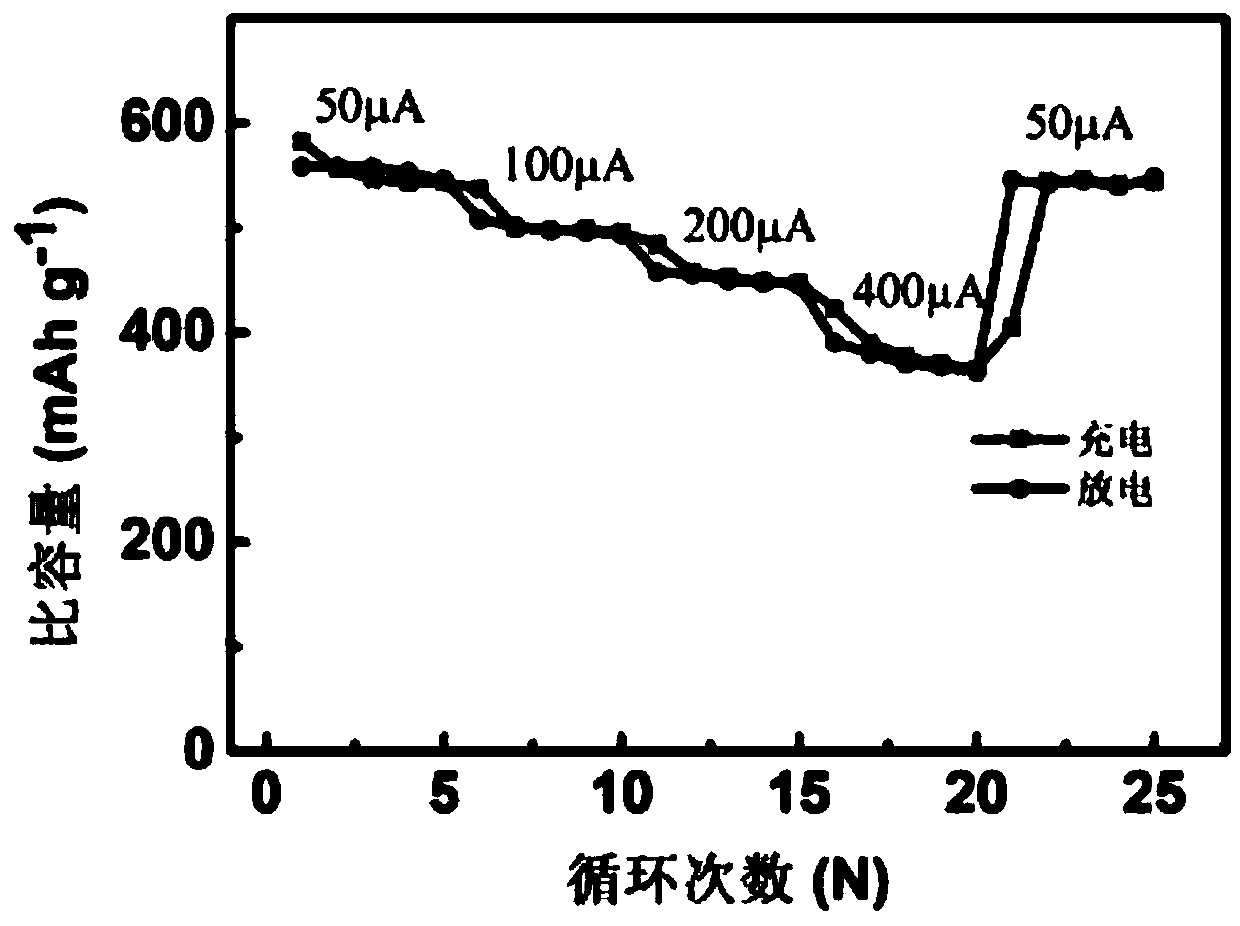

[0046] This example uses Li 6 P.S. 5 Cl sulfide electrolyte, which is used not only as the positive electrode active material, but also as the material of the solid electrolyte layer. A variety of carbon composite materials are commercially used as conductive carbon materials, lithium-indium alloys are used as negative electrode materials, and solid lithium-ion batteries are assembled. The specific steps are as follows:

[0047] (1) will P 2 S 5 (Aladding 99%), Li 2 S (Alfa 99.9%) and LiCl (Aladding 99.99%) were ball milled for 1 hour at a speed of 100 rpm; then the mixture was sealed and heat-treated at 550°C for 3 hours to obtain Li 6 P.S. 5 Cl sulfide electrolyte.

[0048] (2) Mixing Super P and VGCF according to the mass ratio of 2:1 at a speed of 300rpm for 1h by dry ball milling can complete the preparation of various carbon composite materials.

[0049] (3) Will Li 6 P.S. 5 The composite material of Cl sulfide electrolyte and various carbons (mass ratio 70:30) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com