808 nanometer near-infrared excited composite antibacterial coating and preparation method thereof

A composite antibacterial and near-infrared technology, applied in the field of materials science and nanometers, can solve the problems of increased bacterial resistance, tissue burns, super bacteria, etc., and achieve the effects of convenient preparation, shortening treatment time, and improving antibacterial efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The second aspect of the present invention provides the preparation method of the above-mentioned 808 nanometer near-infrared excitation composite antibacterial coating, the steps include:

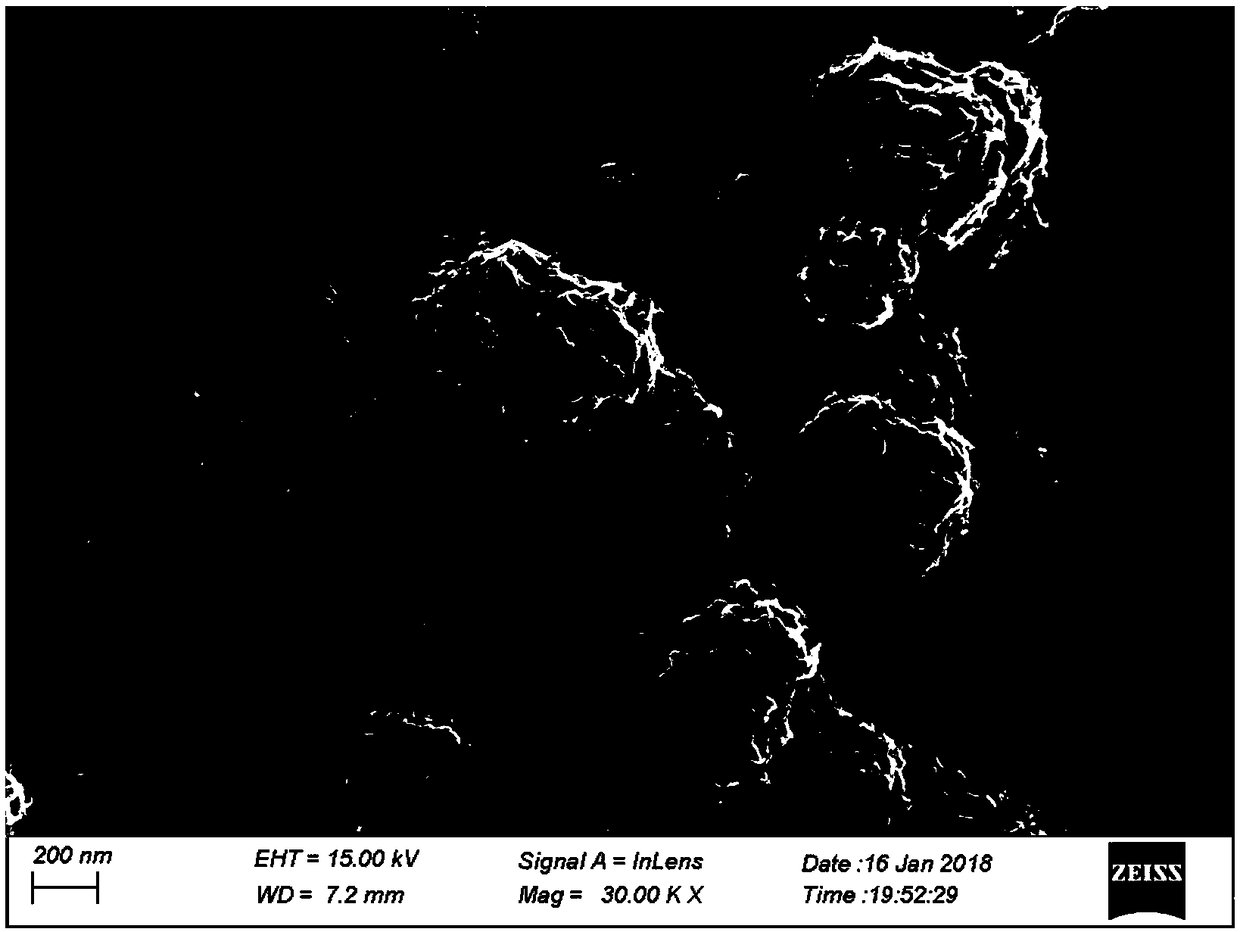

[0020] S1. Preparation of polyethylene glycol-modified molybdenum sulfide nanoflowers: Sodium molybdate dihydrate, thioacetamide, and polyethylene glycol were dissolved in deionized water and stirred to prepare a mixed solution A.

[0021] S2. Pour the mixed solution A described in step S1 into the reaction kettle with the titanium sheet, react at 190-220° C. for 23-25 hours, and take out the titanium sheet for later use after the reaction is completed;

[0022] S3. Loading of antibiotics: the titanium sheet obtained in step S2 is dried and soaked in an antibiotic solution to load the drug to obtain the drug-loaded titanium sheet;

[0023] S4. Spin coating of chitosan: Adsorb the drug-loaded titanium sheet obtained in step S3 on a spin coater, and then spin coat the chitosan solut...

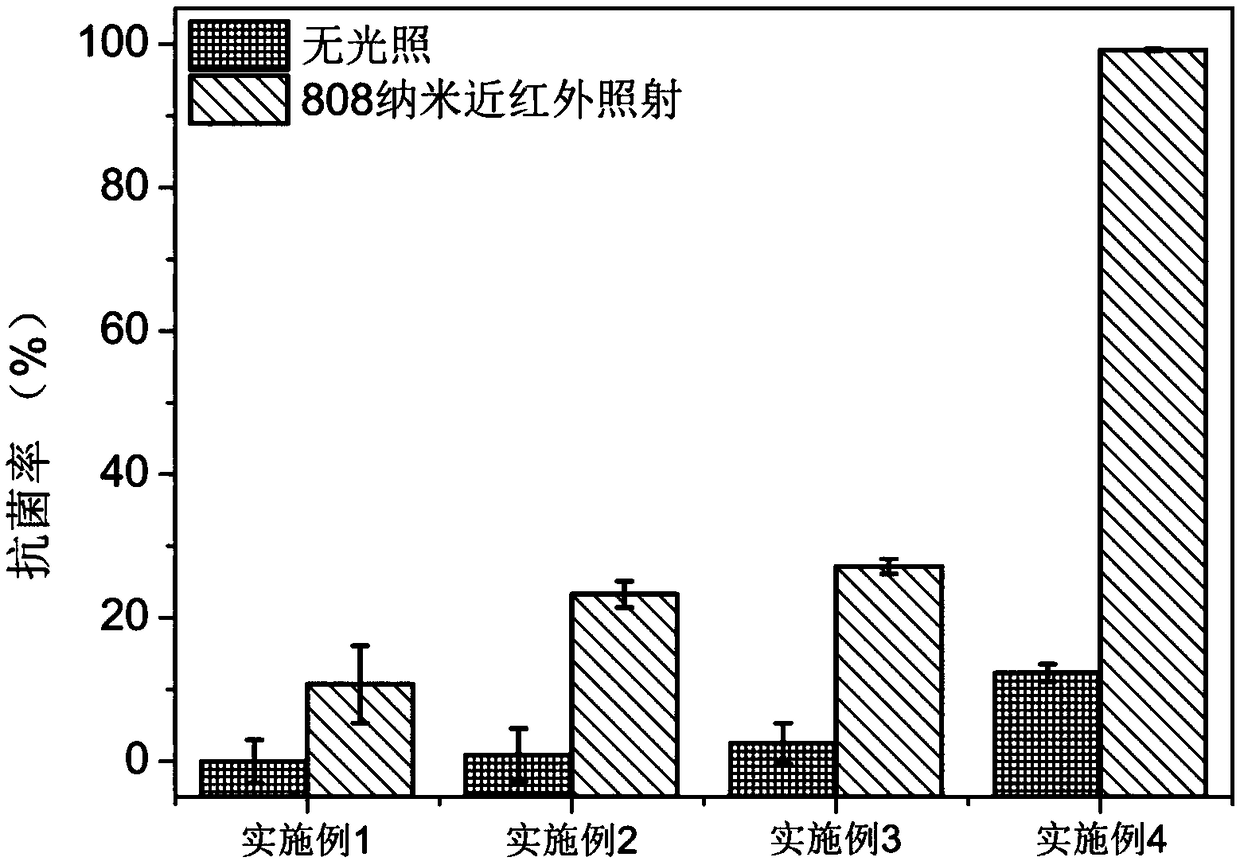

Embodiment 1

[0035] (1) Polish the pure titanium sheet with 240#, 400#, 600#, 800#, and 1200# sandpaper in sequence, then ultrasonically wash it with acetone, ethanol, and deionized water for 5 minutes, and dry it for later use.

Embodiment 2

[0037] (1) Polish the pure titanium sheet with 240#, 400#, 600#, 800#, and 1200# sandpaper in sequence, then ultrasonically wash it with acetone, ethanol, and deionized water for 5 minutes, and dry it for later use.

[0038] (2) Dissolve 20 mg of sodium molybdate dihydrate, 40 mg of thioacetamide and 0.66 g of polyethylene glycol in 40 mL of deionized water, and stir for 30 minutes to mix the solution evenly. The concentration of sodium molybdate dihydrate is 0.5 mg / mL, the concentration of thioacetamide is 1 mg / mL, and the concentration of polyethylene glycol is 0.0165 g / mL. Then pour the mixed solution into the reaction kettle with the treated titanium sheet in step one. The reaction kettle was placed in a muffle furnace at 200°C for 24 hours, and after natural cooling, the titanium sheet was taken out for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com