Core-shell type hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst, core-shell technology, applied in catalysts, hydrogenation to hydrocarbons, molecular sieve catalysts, etc., can solve problems such as lack of compatibility, achieve excellent catalytic performance, shorten migration paths, and increase the effect of hydroxyl density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

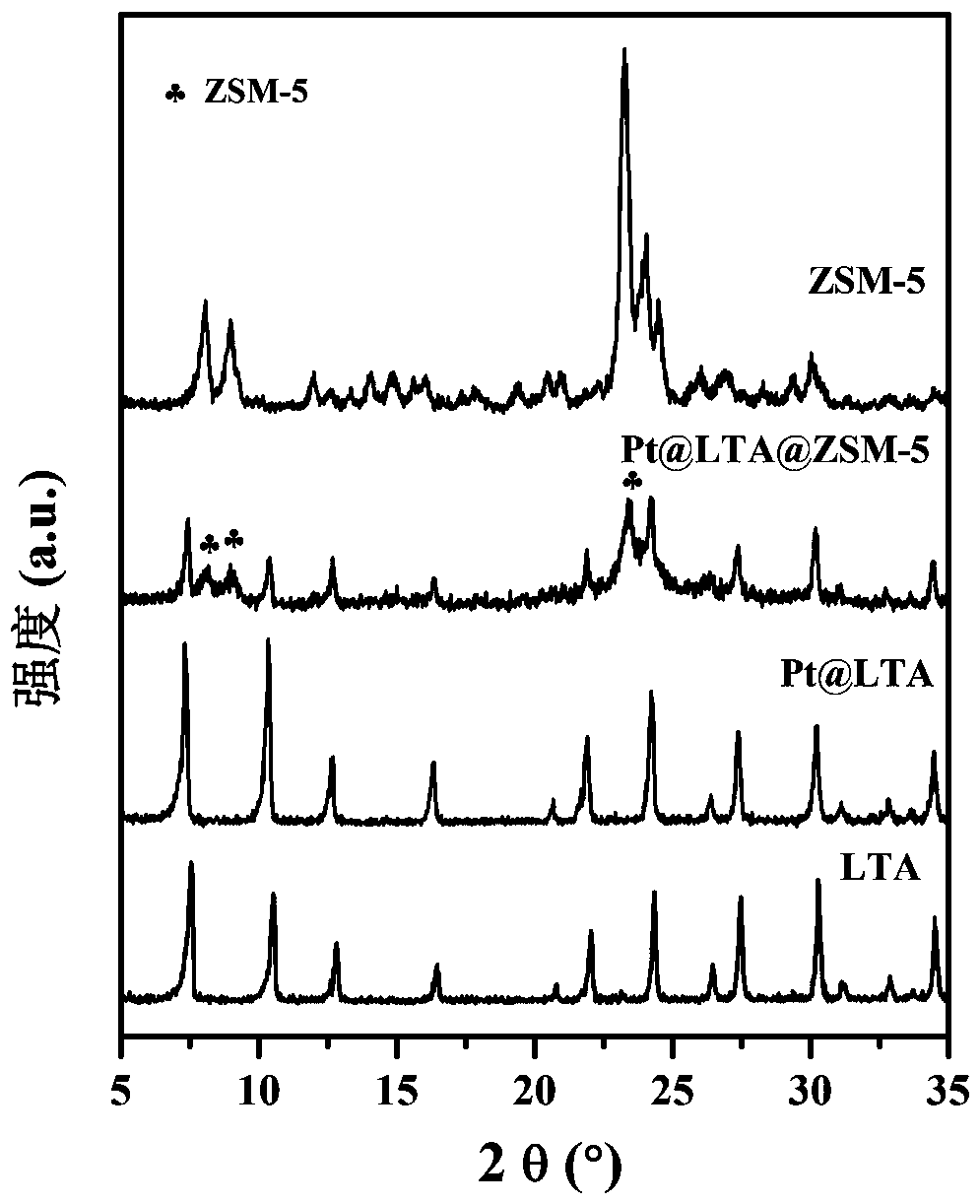

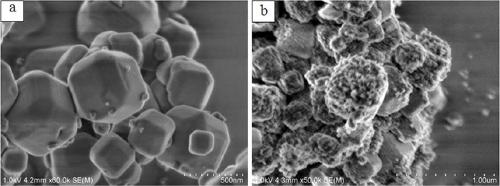

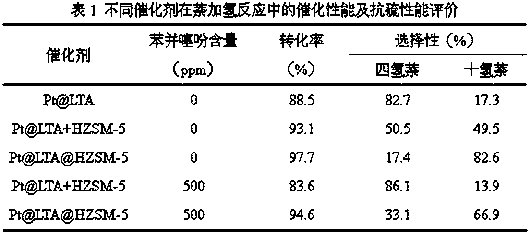

[0048] Take 30.3mmol sodium metaaluminate, 24.6mmol sodium hydroxide, 11mmol fumed silica, add 19.8mL deionized water successively, stir at 60℃ for 3h, then add 0.24mmol Pt(NH 3 ) 4 Cl 2 , Continue to stir for 1h. Then it was put into a stainless steel reactor with PTFE lining, and reacted with dynamic hydrothermal crystallization at a constant temperature of 100°C for 24 hours. The obtained solid product was washed to neutrality, dried, calcined at 350℃ for 2h in air atmosphere, and then subjected to 10% H at 350℃ 2 / Ar was reduced for 2h to prepare Pt@LTA samples encapsulated with Pt metal clusters.

[0049] Take 2 g of the Pt@LTA sample prepared above, add 10 mL of ethanol and deionized water (1:1) to the mixture, and sonicate for 1 hour to obtain dispersion A.

[0050] Take 2.98mmol sodium metaaluminate, 1.22mmol sodium hydroxide, and 33.6mmol tetrapropylammonium hydroxide 25wt% aqueous solution, add 32mL deionized water and stir until clear, then add 55.4mmol ethyl orthosilica...

Embodiment 2

[0056] Take 30.3mmol sodium metaaluminate, 101.2mmol sodium hydroxide, 22mmol fumed silica, sequentially add 21.5mL deionized water, stir at 60℃ for 3h, add 0.12mmol [Pd(NH 2 CH 2 CH 2 NH 2 ) 2 ]Cl 2 , Continue to stir for 1h. Then it was put into a stainless steel reaction kettle with a polytetrafluoroethylene lining, and reacted for 12 hours at a constant temperature of 100°C for dynamic hydrothermal crystallization. The obtained solid product was washed to neutrality, dried, calcined at 350℃ for 2h under air atmosphere, and then subjected to 10% H at 300℃ 2 / Ar reduction for 3h to prepare Pd@LTA samples encapsulated with Pd metal clusters.

[0057] Take 1.5 g of the Pd@LTA sample prepared above, add 10 mL of a mixture of ethanol and deionized water (1:1), and ultrasonicate for 1 h to obtain dispersion A.

[0058] Take 2.98mmol of sodium metaaluminate, 2.21mmol of sodium hydroxide, add 50.4mmol of tetrapropylammonium hydroxide 25wt% aqueous solution to 21mL of deionized water and...

Embodiment 3

[0062] Take 30.3mmol sodium metaaluminate, 63.4mmol sodium hydroxide, 18.4mmol fumed silica, sequentially add 22.8mL deionized water, stir at 60℃ for 3h, add 0.12mmol [Ir(NH 3 ) 5 Cl]Cl 2 , Continue to stir for 1h. Then it was put into a stainless steel reactor with PTFE lining, and reacted with dynamic hydrothermal crystallization at a constant temperature of 80°C for 24h. The obtained solid product was washed to neutrality, dried, calcined at 350℃ for 2h under air atmosphere, and then subjected to 10% H at 370℃ 2 / Ar was reduced for 2h, and Ir@LTA samples encapsulated with Ir nanoclusters were prepared.

[0063] Take 2.3 g of the Ir@LTA sample prepared above, add 10 mL of a mixture of ethanol and deionized water (1:1), and ultrasonicate for 1 hour to obtain dispersion A.

[0064] Take 2.98mmol of sodium metaaluminate, 2.9mmol of sodium hydroxide, add 60.1mmol of tetrapropylammonium hydroxide 25wt% aqueous solution to 44.3mL of deionized water and stir until clear, then add 66.8mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com