A kind of alkaline soil restoration material and preparation method thereof

A soil remediation, alkaline technology, applied in the field of soil remediation, can solve the problem of low treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

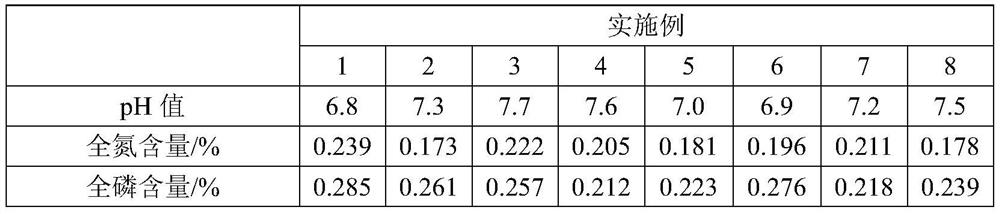

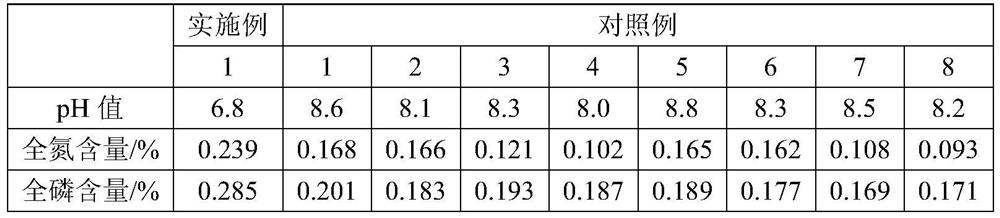

Examples

Embodiment 1

[0022] A kind of alkaline soil restoration material, its preparation method comprises the following steps:

[0023] (1) Weigh 18 parts of polyacrylamide, 8.9 parts of phosphoric acid, 7.2 parts of oxalic acid, 4.3 parts of concentrated sulfuric acid and 52 parts of N,N-dimethylformamide into the hydrothermal reaction kettle to maintain the hydrothermal reaction temperature of the system React at 85°C for 30 minutes, raise the temperature of the hydrothermal reactor to 158°C for 2.5 hours, and filter the product, ultrasonically wash 3 times with 500mL ethanol, 3 times with 500mL methanol, and 3 times with 500mL ethanol, ℃, -0.08MPa vacuum drying for 13 minutes to obtain phosphoric acid modified polyacrylamide;

[0024] (2) Weigh 32 parts of polytrimethylene carbonate, 30.2 parts of urea and 23.7 parts of ammonium sulfate and add them to a high-speed mixer. The mixing temperature is 80°C and the mixing speed is 650r / min. Mixing reaction for 23min, the product, 16.9 Parts of pho...

Embodiment 2

[0029] A kind of alkaline soil restoration material, its preparation method comprises the following steps:

[0030](1) Weigh 18 parts of polyacrylamide, 7 parts of phosphoric acid, 6 parts of oxalic acid, 4 parts of concentrated sulfuric acid and 49 parts of N,N-dimethylformamide into the hydrothermal reaction kettle to maintain the hydrothermal reaction temperature of the system React at 85°C for 30 minutes, raise the temperature of the hydrothermal reaction kettle to 145°C for 4 hours, and filter the product, ultrasonically wash 3 times with 500mL ethanol, 3 times with 500mL methanol, and 3 times with 500mL ethanol, and then store at 51°C , -0.08MPa vacuum drying for 13 minutes to obtain phosphoric acid-modified polyacrylamide;

[0031] (2) Weigh 32 parts of polytrimethylene carbonate, 21 parts of urea and 17 parts of ammonium sulfate and add them to a high-speed mixer. The mixing temperature is 80°C and the mixing speed is 650r / min. The mixing reaction is 23min, and the pro...

Embodiment 3

[0036] A kind of alkaline soil restoration material, its preparation method comprises the following steps:

[0037] (1) Weigh 18 parts of polyacrylamide, 11 parts of phosphoric acid, 9 parts of oxalic acid, 6 parts of concentrated sulfuric acid and 60 parts of N,N-dimethylformamide into the hydrothermal reaction kettle to maintain the hydrothermal reaction temperature of the system React at 85°C for 30 minutes, raise the temperature of the hydrothermal reactor to 176°C for hydrothermal reaction for 0.5h, filter the product, ultrasonically wash 3 times with 500mL ethanol, 3 times ultrasonically wash with 500mL methanol, and 3 times ultrasonically wash with 500mL ethanol. ℃, -0.08MPa vacuum drying for 13 minutes to obtain phosphoric acid modified polyacrylamide;

[0038] (2), Weigh 32 parts of polytrimethylene carbonate, 34 parts of urea and 29 parts of ammonium sulfate and add them to a high-speed mixer, the mixing temperature is 80°C, the mixing speed is 650r / min and the mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com