Fast curing resin system and preparation method

A rapid curing and resin technology, applied in the field of epoxy resin rapid curing and accelerator, can solve the problem of shortening the gel time, and achieve the effect of short curing time, broad application background and good comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

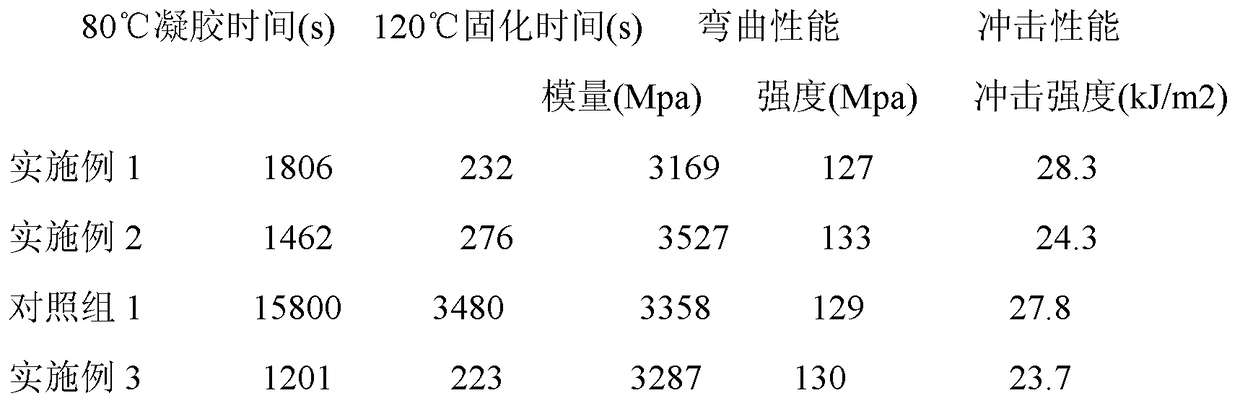

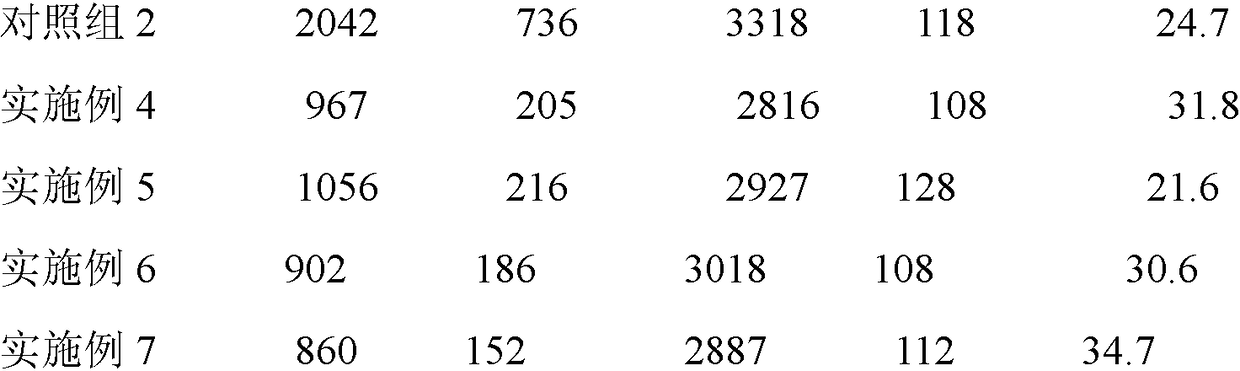

Examples

Embodiment 1

[0046] This embodiment provides a kind of epoxy resin system that can solidify rapidly, and the preparation method of described epoxy resin system is as follows:

[0047] ① Prepare premix 1 and premix 2 according to the formula.

[0048] The formula of premix 1 is: 25 parts of bisphenol A epoxy resin, 17.9 parts of diaminodiphenyl sulfone, and 3 parts of ethylene glycol;

[0049] The formula of premix 2 is: 75 parts of bisphenol A epoxy resin, 13.7 parts of diaminodiphenyl sulfone, 2 parts of ethylene glycol, and 1 part of 1-methylimidazole.

[0050] The equivalent ratio of the epoxy equivalent of the epoxy resin to the active hydrogen equivalent of the curing agent is 1.0 / 1.0.

[0051] ②Mix the ingredients in premix 1 and premix 2 under the condition of 120°C, and carry out vacuum defoaming respectively.

[0052] According to the above recipe, Premix 1 was placed in a reaction vessel at 120°C. Mixed at low temperature for 60 min, mixed premix 2 in the reaction vessel at 12...

Embodiment 2

[0058] This embodiment provides a kind of epoxy resin system that can solidify rapidly, and the preparation method of described epoxy resin system is as follows:

[0059] ① Prepare premix 1 and premix 2 according to the formula.

[0060] Premix 1: 30 parts of bisphenol A epoxy resin, 9.8 parts of DETDA.

[0061] Premix 2: 70 parts of bisphenol A epoxy resin, 12.8 parts of DETDA, 5 parts of butanediol.

[0062] The equivalent ratio of the epoxy equivalent of the epoxy resin to the active hydrogen equivalent of the curing agent is 1.0 / 1.0.

[0063] ②Mix the ingredients in premix 1 and premix 2 under the condition of 80°C, and carry out vacuum defoaming respectively.

[0064] According to the above recipe, put the premix 1 in the reaction vessel at 80°C. Mixing at low temperature for 120 min, mixing premix 2 in the reaction vessel at 80°C for 15 min, and vacuum defoaming respectively, to obtain defoamed premix 1 and defoamed premix 2.

[0065] ② Mix the defoamed premix 1 and ...

Embodiment 3

[0079] This embodiment provides a kind of epoxy resin system that can solidify rapidly, and the preparation method of described epoxy resin system is as follows:

[0080] ① Prepare premix 1 and premix 2 according to the formula.

[0081] Premix 1: 30 parts of bisphenol A epoxy resin, 6.8 parts of DETDA, 5 parts of ethylene glycol;

[0082] Premix 2: 70 parts of bisphenol A epoxy resin, 15.8 parts of DETDA, 2-ethyl-4-methylimidazole.

[0083] ②Mix the ingredients in premix 1 and premix 2 under the condition of 40°C, and carry out vacuum defoaming respectively.

[0084] According to the above recipe, premix 1 was placed in a reaction vessel at 40°C. Mixed at low temperature for 180 min, mixed premix 2 in the reaction vessel at 80°C for 15 min, and vacuum defoamed respectively to obtain defoamed premix 1 and defoamed premix 2.

[0085] ③ Mix the defoamed premix 1 and defoamed premix 2 at 80°C.

[0086]Mix premix 1 and premix 2 at 80°C according to 8:2 (mass ratio) for 20 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com