Flame-retardant antibacterial PC-ABS alloy and preparation method thereof

A PC-ABS and alloy technology, applied in the field of flame-retardant and antibacterial PC-ABS alloy and its preparation, can solve the problems of ineffective antibacterial, short drug effect duration, poor heat resistance, etc., and achieve high production efficiency and excellent mechanical properties Good, the effect of improving the antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

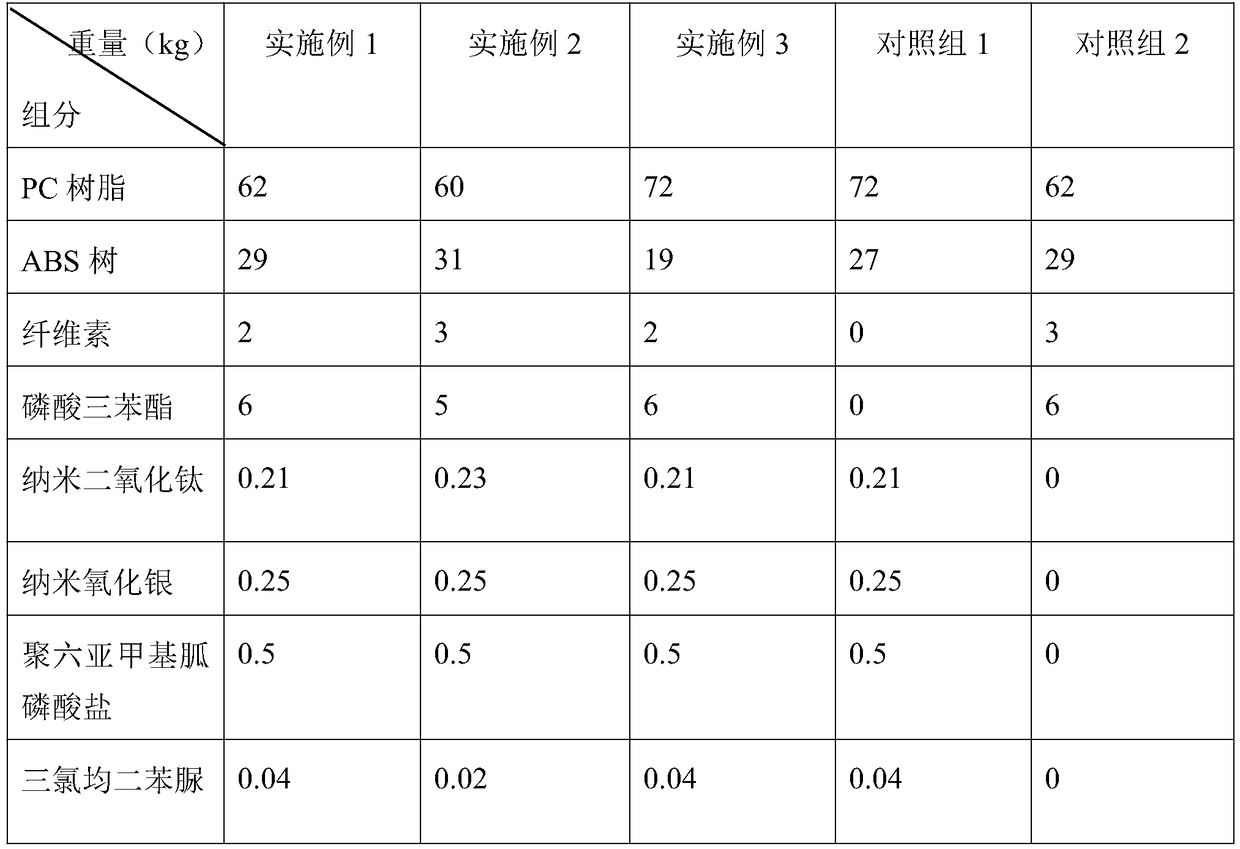

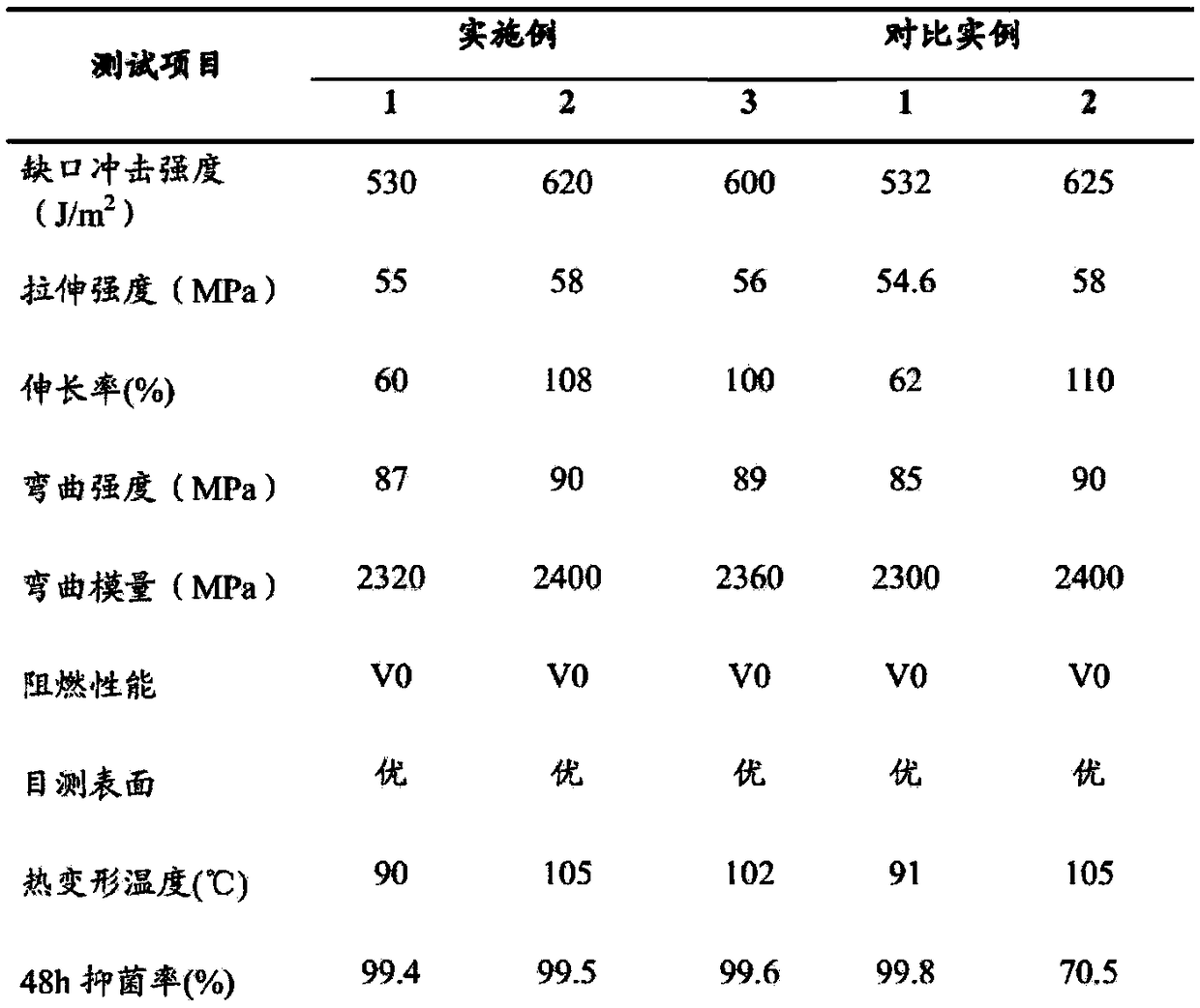

Embodiment 1

[0029] A kind of preparation of flame-retardant antibacterial PC-ABS alloy material, comprises the steps:

[0030] (1) Drying, take 62kg of PC pellets by weight and place them in an electric heating constant temperature blower drying oven at 120°C for 12 hours. Oven drying at 80°C for 12 hours;

[0031] (2) blending, the polyhexamethylene of the PC pellet of 62kg, the ABS particle of 29kg, the cellulose of 2kg, the triphenyl phosphate of 6kg, the nano-titanium dioxide of 0.21kg, the nano-silver oxide of 0.25kg, the polyhexamethylene of 0.5kg The trichlorodiphenyl urea of base guanidine phosphate, 0.04kg mixed 3.5 minutes in high-speed mixer;

[0032] (3) Extrusion. Melt and extrude the mixed PC / ABS premix in a twin-screw extruder with an extrusion temperature of 190°C to 240°C, granulate after cooling, and dry in a vacuum oven for 2 hours. to get the final product.

Embodiment 2

[0034] A kind of preparation of flame-retardant antibacterial PC-ABS alloy material, comprises the steps:

[0035] (1) Drying, take 60kg of PC pellets by weight and place them in an electric heating constant temperature blower drying oven at 120°C for 12 hours, weigh 31kg of ABS particles and dry them in an electric heating constant temperature blast drying Oven drying at 80°C for 12 hours;

[0036] (2) blending, the polyhexamethylene of the PC pellet of 60kg, the ABS particle of 13kg, the cellulose of 3kg, the triphenyl phosphate of 5kg, the nano-titanium dioxide of 0.23kg, the nano-silver oxide of 0.25kg, the polyhexamethylene of 0.5kg The trichlorodiphenyl urea of base guanidine phosphate, 0.02kg mixed 3.5 minutes in high-speed mixer;

[0037] (3) Extrusion. Melt and extrude the mixed PC / ABS premix in a twin-screw extruder with an extrusion temperature of 190°C to 240°C, granulate after cooling, and dry in a vacuum oven for 2 hours. to get the final product.

Embodiment 3

[0039] A kind of preparation of flame-retardant antibacterial PC-ABS alloy material, comprises the steps:

[0040] (1) Drying, take 72kg of PC granules by weight and place them in an electric heating constant temperature blower drying oven at 120°C for 12 hours, weigh 19kg of ABS granules and dry them in an electric heating constant temperature blower drying oven Oven drying at 80°C for 12 hours;

[0041] (2) blending, the polyhexamethylene of the PC pellet of 72kg, the ABS particle of 19kg, the cellulose of 2kg, the triphenyl phosphate of 6kg, the nano-titanium dioxide of 0.21kg, the nano-silver oxide of 0.25kg, the polyhexamethylene of 0.5kg The trichlorodiphenyl urea of base guanidine phosphate, 0.04kg mixed 3.5 minutes in high-speed mixer;

[0042] (3) Extrusion. Melt and extrude the mixed PC / ABS premix in a twin-screw extruder with an extrusion temperature of 190°C to 240°C, granulate after cooling, and dry in a vacuum oven for 2 hours. to get the final product.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com