Soluble polyelectrolyte compound and method for flame-retardant finishing of protein fiber

A technology of protein fiber and polyelectrolyte, which is applied in fiber treatment, animal fiber, flame-retardant fiber, etc., can solve the problems of restricting industrial application and complicated process, and achieve good washing resistance, simple process, low phosphorus and nitrogen content high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

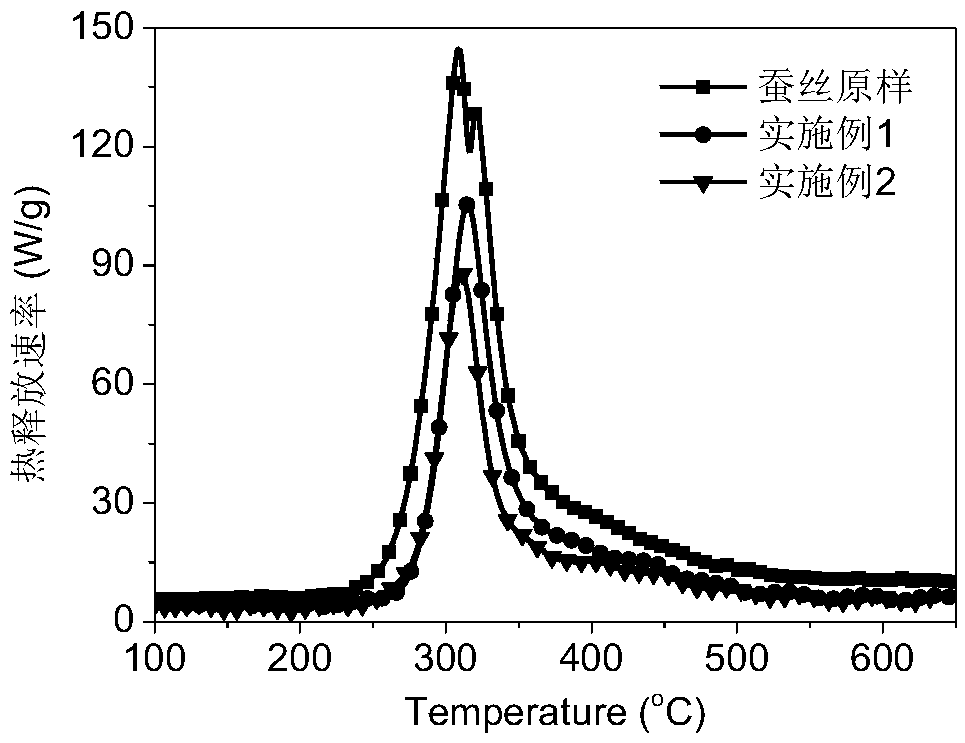

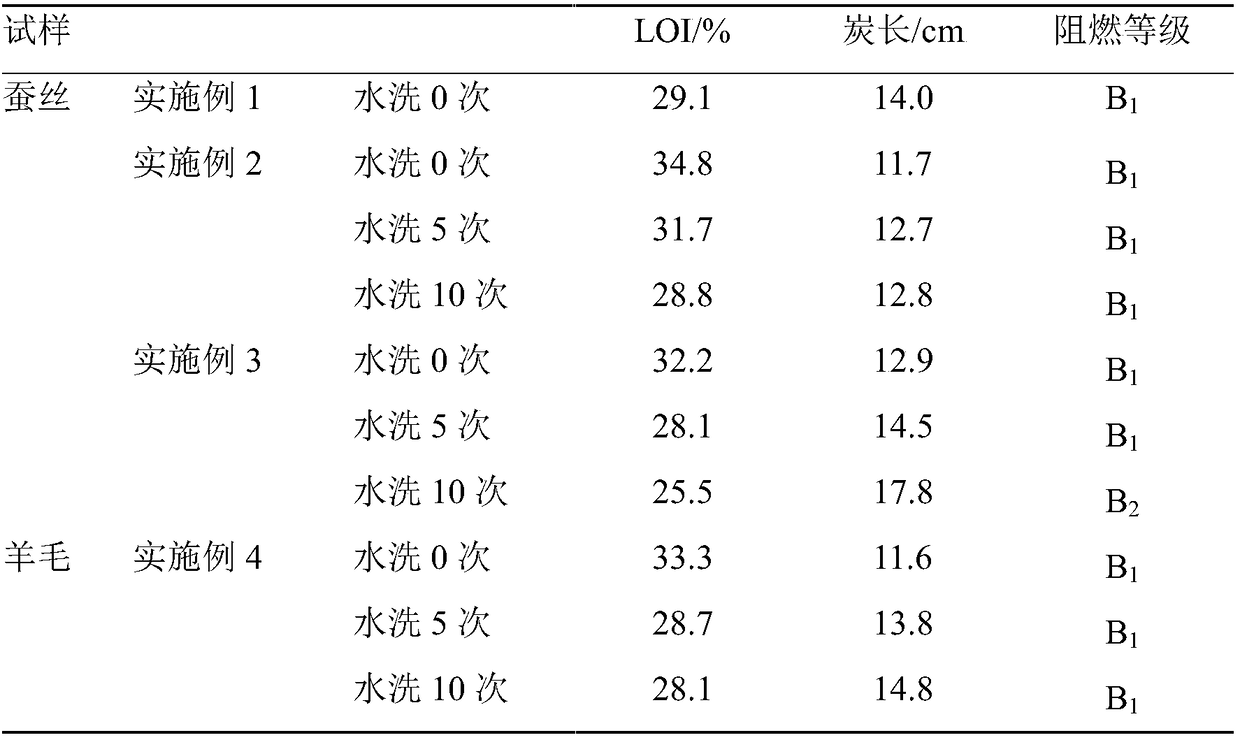

[0028] Example 1: Silk Fabric - Citric Acid - One Impregnation

[0029] (1) Preparation of soluble polyelectrolyte complex: first dissolving chitosan (2%) in citric acid (10%) solution, and using acetic acid to adjust the pH value of the solution to 2 to obtain a chitosan solution. Then an equal volume of phytic acid (24%) solution is slowly added dropwise to the chitosan solution, and stirred evenly to obtain a uniform and transparent soluble phytic acid / chitosan polyelectrolyte complex system, and the concentration of phytic acid in the solution is now 12%, the concentration of chitosan is 1%, the concentration of citric acid is 5%, and the pH value of the solution is 2.

[0030] (2) Preparation of flame-retardant silk fabric: immerse the silk fabric in the polyelectrolyte complex solution obtained in step (1) for 10 minutes, then roll off excess water, the excess rate is 100%, and dry the silk fabric at 70°C . Then the silk fabric was treated in pH6 citric acid / sodium cit...

Embodiment 2

[0031] Example 2: Silk fabric - citric acid - five dips

[0032] (1) Preparation of soluble polyelectrolyte complex: first dissolving chitosan (4%) in citric acid (12%) solution, and using acetic acid to adjust the pH value of the solution to 1 to obtain a chitosan solution. Then an equal volume of phytic acid (20%) solution is slowly added dropwise to the chitosan solution, and stirred evenly to obtain a uniform and transparent soluble phytic acid / chitosan polyelectrolyte complex system, and now the concentration of phytic acid in the solution is 10%, the concentration of chitosan is 2%, the concentration of citric acid is 6%, and the pH value of the solution is 1.

[0033] (2) Preparation of flame-retardant silk fabric: immerse the silk fabric in the polyelectrolyte complex solution obtained in step (1) for 10 minutes, then roll off excess water, the excess rate is 100%, and dry the silk fabric at 70°C . Then the silk fabric was treated in pH5 citric acid / sodium citrate bu...

Embodiment 3

[0034] Embodiment 3: silk fabric-hydrochloric acid-five dippings

[0035] (1) Preparation of soluble polyelectrolyte complex: first dissolving chitosan (4%) in hydrochloric acid solution with a pH value of 1 to prepare a chitosan solution. Then an equal volume of phytic acid (20%) solution is slowly added dropwise to the chitosan solution, and stirred evenly to obtain a uniform and transparent soluble phytic acid / chitosan polyelectrolyte complex system, and now the concentration of phytic acid in the solution is 10%, the concentration of chitosan is 2%, and the pH value of the solution is 1.

[0036](2) Preparation of flame-retardant silk fabric: immerse the silk fabric in the polyelectrolyte complex solution obtained in step (1) for 10 minutes, then roll off excess water, the excess rate is 100%, and dry the silk fabric at 70°C . Then the silk fabric was treated in pH5 citric acid / sodium citrate buffer solution for 5 minutes, then washed with water and dried at 70°C. The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com