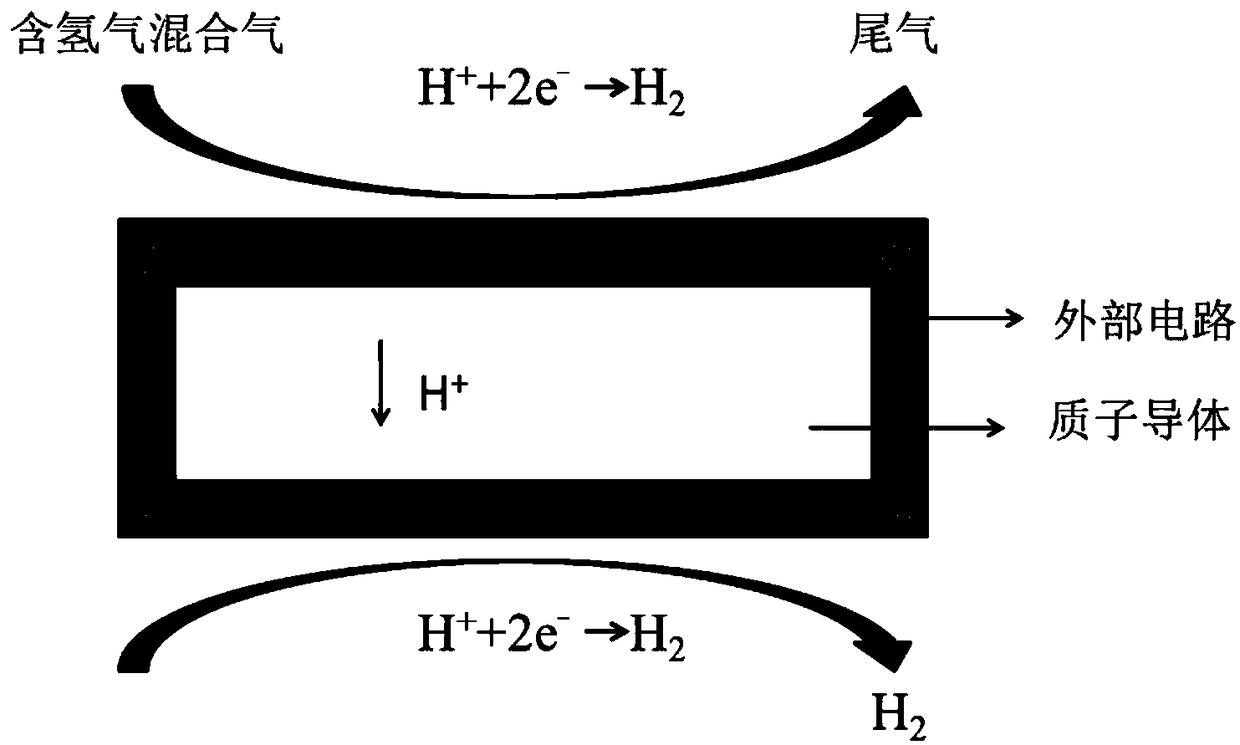

Proton-electron mixed conductor hydrogen permeation membrane, preparation method thereof and hydrogen permeation membrane reactor

A hybrid conductor and electronic conductor technology, applied in the field of hydrogen permeation membrane reactor, can solve the problems of not being able to be used as a hydrogen permeation membrane, lack of electron transfer channels, unable to achieve hydrogen purification, etc., and achieve enhanced mechanical strength and anti-oxidation performance, high The effect of hydrogen permeation rate and strong anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

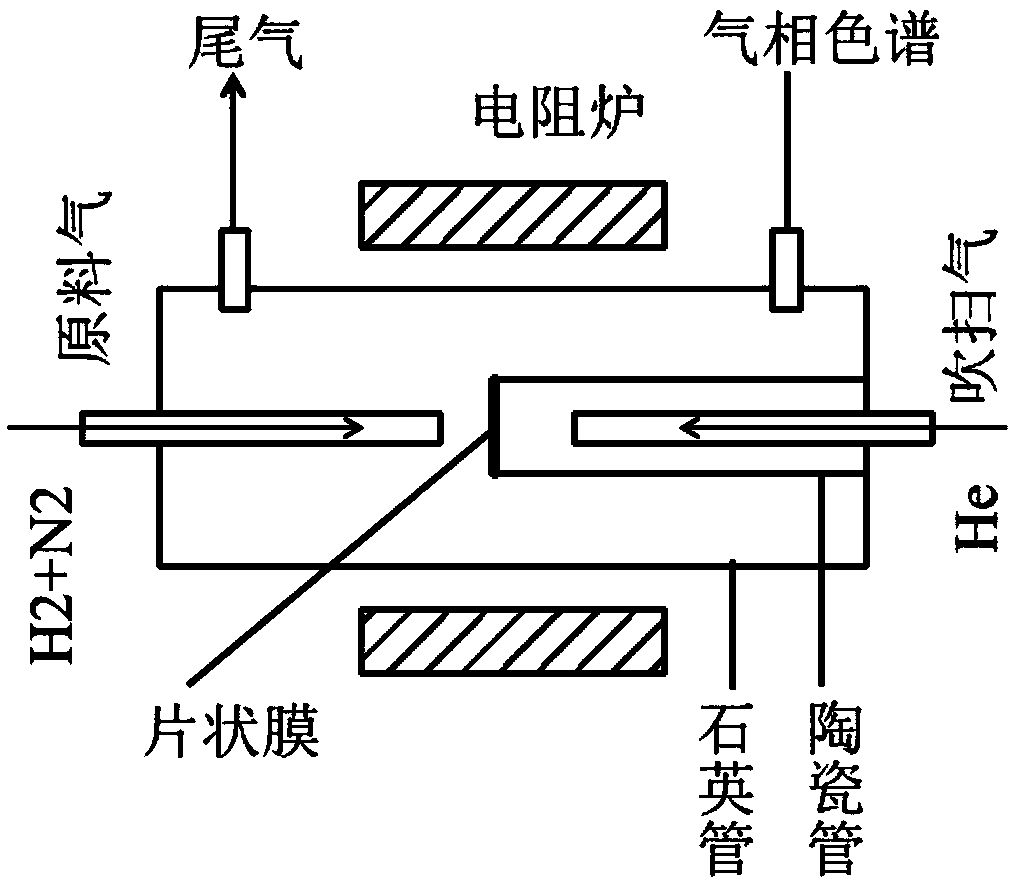

Method used

Image

Examples

Embodiment 1

[0043] Pour 1g polybenzimidazole (mPBI) and 10mL dimethylacetamide (DMAC) into the flask, heat at 120℃ with an electric heating mantle, and stir magnetically for 8h, then add 0.063g (5%) graphite and 5mL dimethylacetamide ( DMAC) Magnetic stirring for 8 hours, finally adding crosslinking agent 0.20g (20%) triglycidyl isocyanurate (TGIC), heating at 60° C. with an electric heating mantle, and magnetic stirring for 2 hours to obtain a mixed solution. The mixed solution was ultrasonically shaken for 30 minutes to remove air bubbles. The mixed solution was cast on a glass plate in a 60°C oven to form a film. After 2h, the solvent was volatilized. The temperature was raised to 160°C and kept for 5-6h. Finally, the film was taken out and soaked in deionized water until the film fell off naturally.

[0044] The membrane was cut into a disc with a radius of 0.5 cm and the membrane was immersed in 1 mol / L phosphoric acid for 24 hours. The surface of the membrane was taken out and brushed ...

Embodiment 2-3

[0054] Example 2-3 is the same as Example 1, except that the amount of crosslinking agent added is 0.25g (25%) and 0.30g (30%) respectively, and the mechanical strength is shown in Table 3.

[0055] table 3

[0056]

Embodiment 4

[0058] Pour 1g of polybenzimidazole (mPBI) and 10mL of dimethylacetamide (DMAC) into the flask, heat at 120℃ with an electric heating mantle, magnetically stir for 8h, then add 0.14g (10%) graphene and 5mL dimethylacetamide (DMAC) Magnetic stirring for 8 hours, finally adding crosslinking agent 0.25g (25%) triglycidyl isocyanurate (TGIC), heating with an electric heating mantle at 60°C and magnetic stirring for 2 hours to obtain a mixed solution. The mixed solution was ultrasonically shaken for 30 minutes to remove air bubbles. The mixed solution was cast into a film on a glass plate in an oven at 60°C, and the solvent was evaporated after 2h; the temperature was raised to 160°C for 5-6h, and finally the membrane was taken out and soaked in deionized water until the membrane fell off naturally.

[0059] The membrane was cut into a disc with a radius of 0.5 cm and the membrane was immersed in 1 mol / L phosphoric acid for 24 hours. The surface of the membrane was taken out and brush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com