Trivalent iridium imine complex containing iridium nitrogen double bonds, preparation method and application of trivalent iridium imine complex

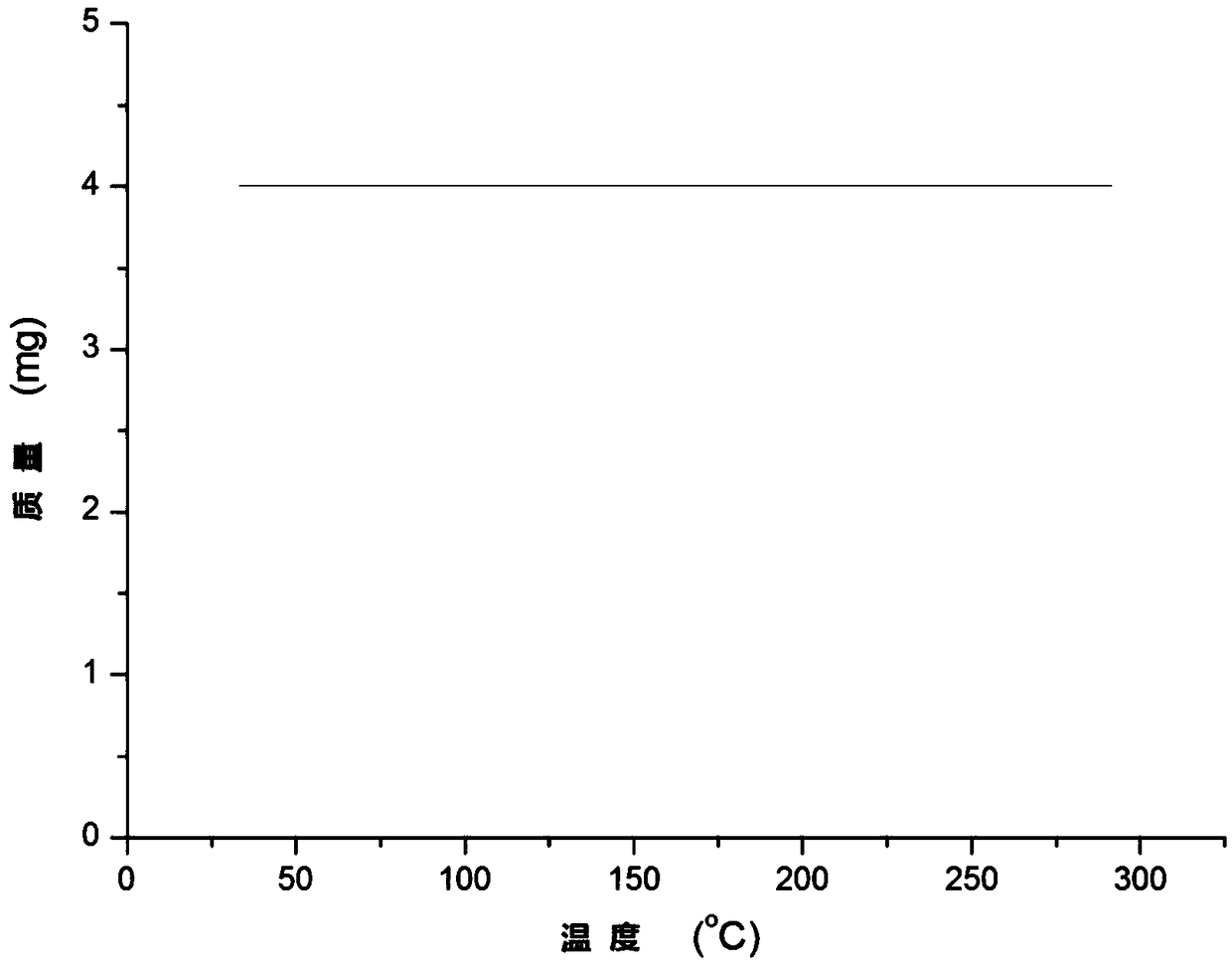

A complex and amine compound technology, applied in the field of synthetic chemistry, to achieve high yield, simple preparation method, and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

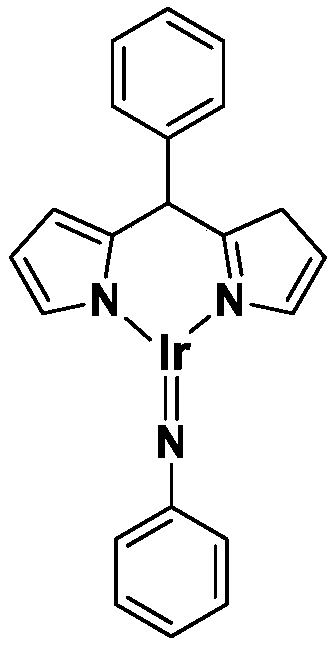

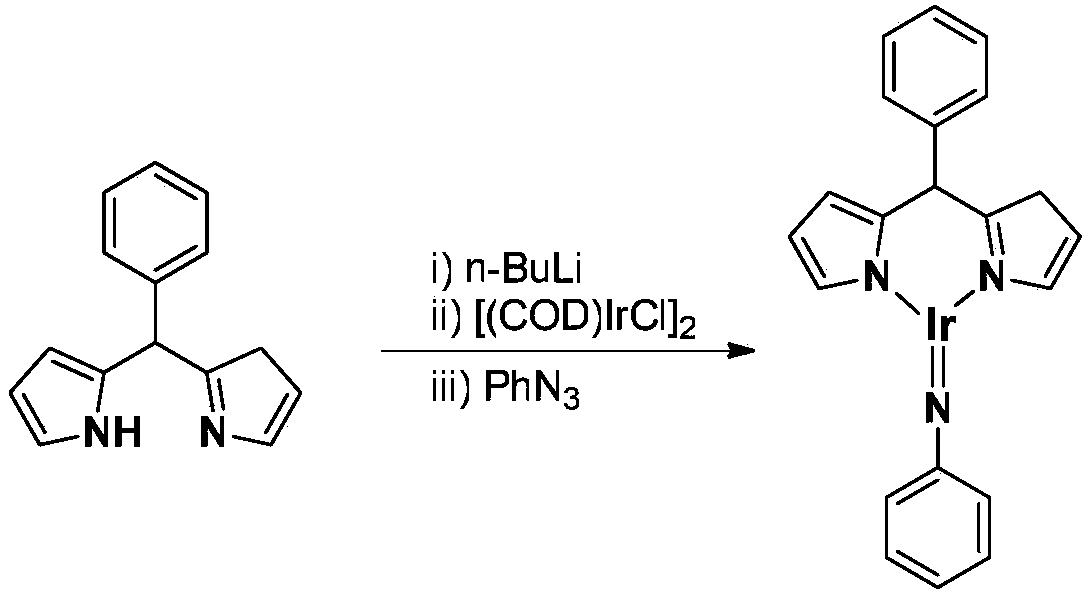

[0022] Embodiment 1: the synthesis of the trivalent iridium imine compound containing iridium nitrogen double bond

[0023]

[0024] At -78°C, n-BuLi (1.6M) n-hexane solution (0.50mL, 0.8mmol) was slowly added dropwise to phenyldipyrrole C 15 h 14 N 2 (127.0mg, 0.57mmol) in tetrahydrofuran solution, stirred at this temperature for 1 hour, slowly rose to room temperature and continued to react for 1 hour, then added monovalent iridium precursor cyclooctadiene iridium chloride dimer [(COD) IrCl] 2 (188.0mg, 0.28mmol), continue to react at room temperature for 3 hours. Then the phenylazide PhN 3 (50.0mg, 0.42mmol) was added to the reaction system and reacted for another 3 hours. After the reaction, stand and filter, and dry the solvent under reduced pressure. The obtained crude product is separated by column chromatography (petroleum ether / dichloromethane (v / v)=8:1) to obtain the dark red target product trivalent iridium Amine complex C 21 h 18 IrN 3 (115 mg, 81% yiel...

Embodiment 2

[0027] Example 2: Trivalent iridium imine complexes catalyze the trans-Malkovamination of olefins

[0028]

[0029] The catalyst prepared in Example 1 was used to catalyze the trans-Martensoyl hydroamination of olefins: to styrene (1mmol, 104mg) and aniline (1mmol, 93mg) was added an imine complex containing trivalent iridium (0.001mmol, 5.0mg) toluene solution, the reaction temperature is 25°C, and the reaction time is 90 minutes. After the end, the concentrated reaction solution is directly separated by silica gel column chromatography, dried until the quality remains unchanged, and the corresponding amine compound C is obtained. 14 h 15 N (177 mg, 88% yield), elemental analysis: C 85.24, H 7.66, N 7.10 (theoretical); C 85.33, H 7.69, N 7.12 (actual).

Embodiment 3

[0030] Example 3: Trivalent iridium imine complexes catalyze the trans-Malkovamination of olefins

[0031]

[0032] The catalyst prepared in Example 1 was used to catalyze the trans-Martensoyl hydroamination reaction of olefins: to styrene (1mmol, 104mg) and aniline (1mmol, 93mg) was added an imine complex containing trivalent iridium (0.002mmol, 10.0mg) toluene solution, the reaction temperature is 40°C, and the reaction time is 80 minutes. After the end, the concentrated reaction solution is directly separated by silica gel column chromatography, dried until the quality remains unchanged, and the corresponding amine compound C is obtained. 15 h 17 N (190 mg, 90% yield), elemental analysis: C 85.26, H 8.11, N 6.63 (theoretical); C 85.19, H 8.19, N 6.73 (actual).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com