High-performance navy blue reactive dye composition and application thereof

A reactive dye, high-performance technology, applied in the direction of reactive dyes, azo dyes, organic dyes, etc., can solve the problems of low color fixation rate, navy blue dye solubility, shade, hue, and fastness properties that are difficult to control and meet. heavy metal pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

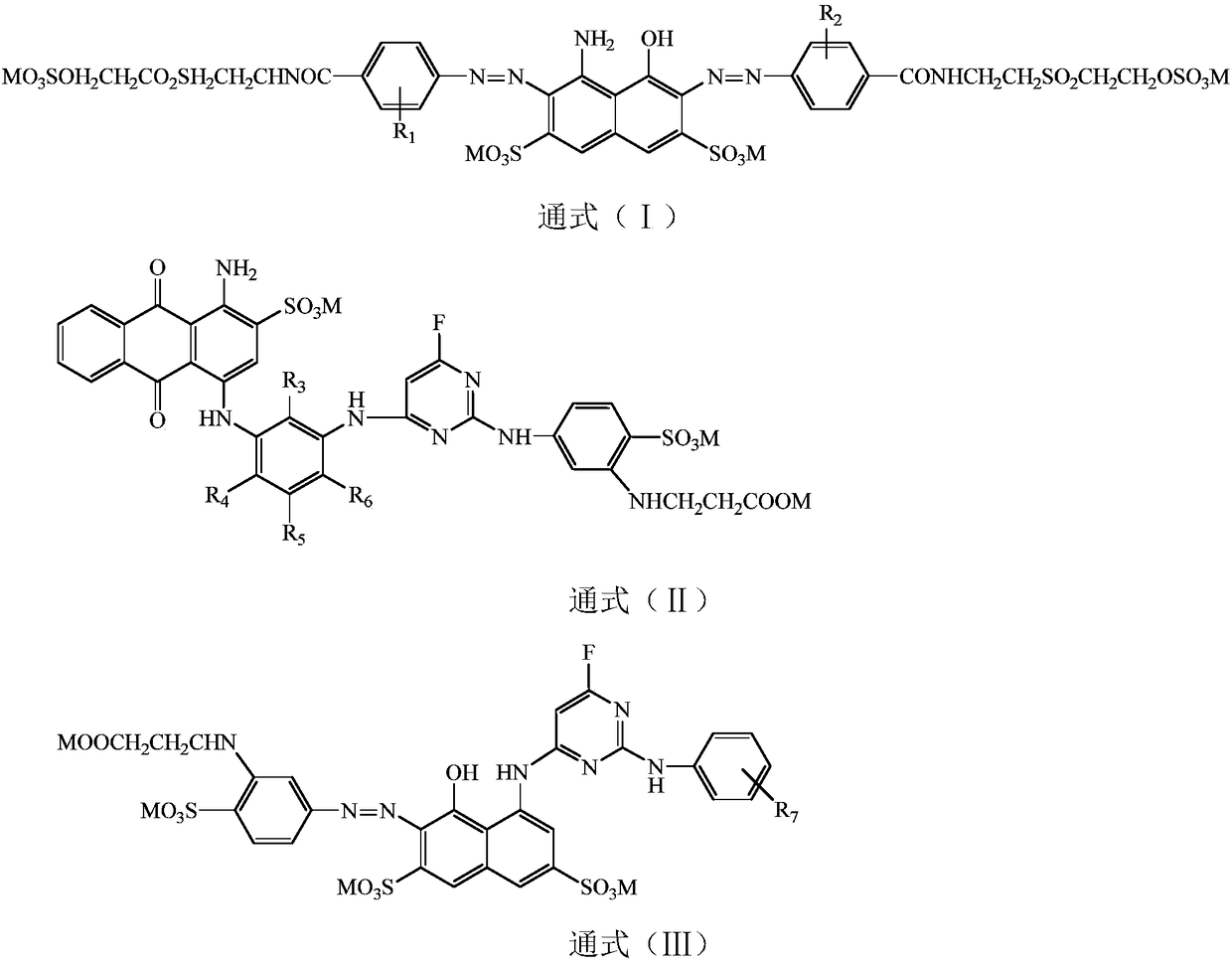

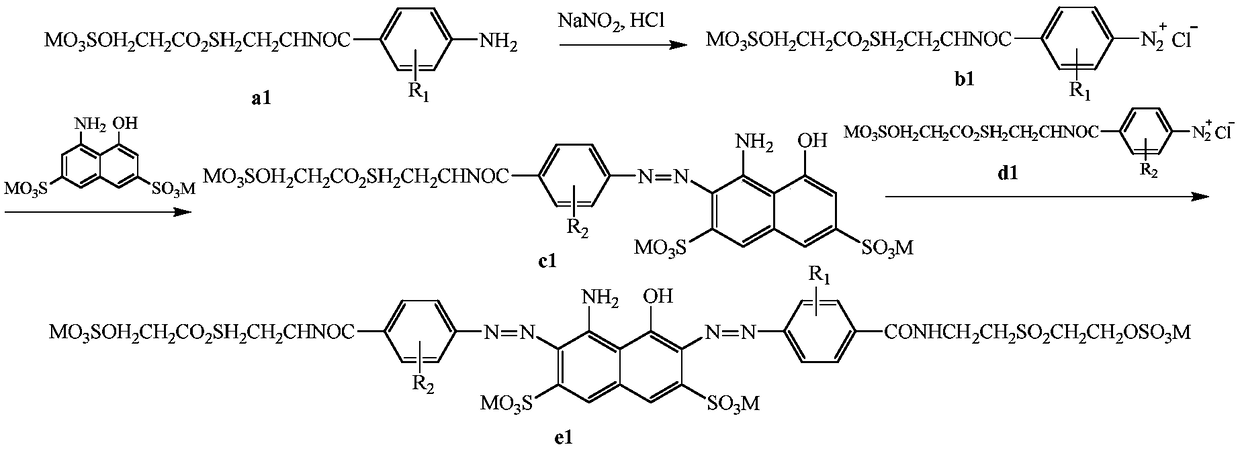

[0073] A high-performance navy blue reactive dye composition is prepared by mixing the compound represented by the general structural formula (I-1), the compound represented by the general formula (II-1) and the compound represented by the general formula (III-1).

[0074]

[0075]

[0076] Compounds shown in reactive dyes I-1, II-1 and III-1 are mixed according to mass percentages of 50%, 47% and 3%, to obtain navy blue reactive dyes; the obtained navy blue reactive dyes and diffusing agent (Methylnaphthalenesulfonic acid formaldehyde condensate, condensation degree is 4, sulfonation degree is 2), water-based polymer dustproof agent and Yuanming powder are 65%, 5%, 0.1% and 29.9% by mass percentage Mixed to obtain a commercial navy blue reactive dye.

[0077] Take 3g of the above-mentioned commercial dye, add 8g of urea, 2.5g of baking soda, 60g of sodium alginate paste, 1g of resist salt and 25.5g of water to make navy blue reactive printing paste, and print the rayon ...

Embodiment 2

[0104] A high-performance navy blue reactive dye composition, which is prepared by mixing the compound shown in the general structural formula (I-2), the compound shown in the general formula (II-2) and the compound shown in the general formula (III-2) into, and their mass percentages are respectively 46-53%, 43-49% and 2-5%.

[0105]

[0106] The reactive dyes I-2, II-2 and III-2 are blended according to the mass percentages of 51.5%, 45% and 3.5%, to obtain navy blue reactive dyes; the obtained navy blue reactive dyes and diffusing agent (Methyl naphthalene sulfonic acid formaldehyde condensate, condensation degree is 4, sulfonation degree is 2), water-based polymer dustproof agent and Yuanming powder are 75%, 5%, 0.1% and 19.9% according to the mass percentage Proportionally mixed to obtain a commercial navy blue reactive dye.

[0107] Take 3g of the above-mentioned commercial dye, add 8g of urea, 2.5g of baking soda, 60g of sodium alginate paste, 1g of resist salt an...

Embodiment 3

[0111] A high-performance navy blue reactive dye composition is prepared by mixing the compound represented by the general structural formula (I-3), the compound represented by the general formula (II-3) and the compound represented by the general formula (III-3).

[0112]

[0113] The compounds shown in reactive dyes I-3, II-3 and III-3 are blended according to the mass percentages of 48%, 48% and 2%, to obtain navy blue reactive dyes; the obtained navy blue reactive dyes and diffusing agent (Methylnaphthalenesulfonic acid formaldehyde condensate, condensation degree is 4, sulfonation degree is 2), water-based polymer dustproof agent and Yuanming powder are 78%, 5%, 0.1% and 16.9% according to the ratio of mass percentage Mixed to obtain a commercial navy blue reactive dye.

[0114] Take 3g of the above-mentioned commercial dye, add 8g of urea, 2.5g of baking soda, 60g of sodium alginate paste, 1g of resist salt and 25.5g of water to make navy blue reactive printing paste,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com