Cooling agent, and vehicle cooling liquid and preparation method thereof

An automobile cooling and coolant technology, applied in the field of coolant, can solve the problems of reducing the thermal conductivity of the cooling system, instability, poor corrosion resistance, etc., to achieve enhanced stability and tolerance, excellent antifreeze performance, and good cooling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

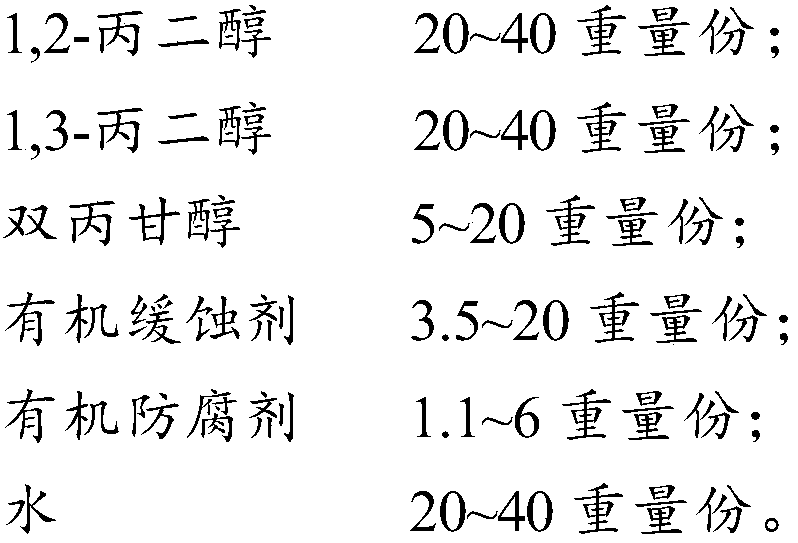

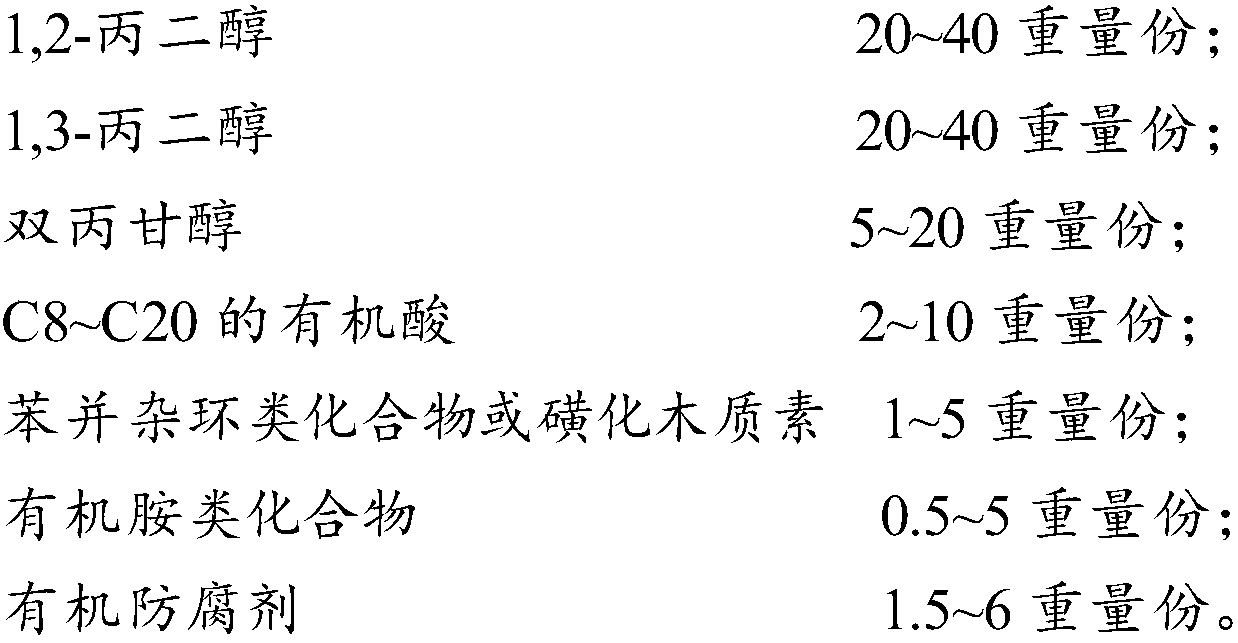

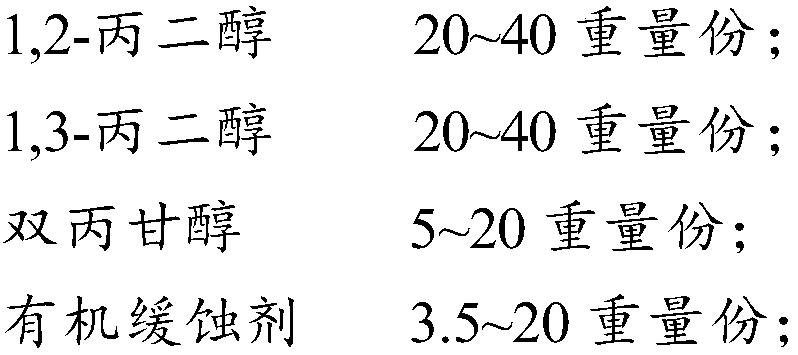

[0051] The present invention also provides a method for preparing the above automobile coolant, comprising: S1) mixing 20-40 parts by weight of 1,2-propanediol with 20-40 parts by weight of water to obtain the first mixed liquid; 20 parts by weight of an organic corrosion inhibitor, 1.1 to 6 parts by weight of an organic preservative and 5 to 20 parts by weight of dipropylene glycol are mixed to obtain a second mixed solution; S2) mixing the first mixed solution and the second mixed solution The liquid is mixed with 20-40 parts by weight of 1,3-propanediol to obtain automobile coolant.

[0052] Mix 20-40 parts by weight of 1,2-propanediol with 20-40 parts by weight of water to obtain the first mixed solution; the 1,2-propanediol and water are the same as above, and will not be repeated here; The method of mixing is preferably stirring.

[0053] Mix 3.5 to 20 parts by weight of an organic corrosion inhibitor, 1.1 to 6 parts by weight of an organic preservative and 5 to 30 part...

Embodiment 1

[0059] 1.1 Mix coolant 1,2-propanediol 20% and deionized water 30.85% in a blender, and stir evenly to obtain the first mixed liquid.

[0060] 1.2 The corrosion inhibitor isononanoic acid 2%, lauric acid 1%, benzotriazole 1%, triethanolamine 0.5% and preservatives 1,2-pentanediol 0.5%, 1,2-octyl glycol 0.5% , 0.1% ethylhexylglycerin and 2% emulsifier sodium lauroyl glutamate were vibrated in an ultrasonic wave to completely dissolve them in 10% dipropylene glycol to obtain a second mixed solution.

[0061] 1.3 Shake the anti-scaling agent 1% sodium polyepoxysuccinate, the defoamer silicone polyether 0.5% and the dyeing agent fluorescent violet 0.05% in the ultrasonic wave to completely dissolve them in 30% 1,3-propylene glycol, Obtain the third mixed solution.

[0062] 1.4 Pour the second mixed solution and the third mixed solution into the first mixed solution in sequence, and stir evenly to obtain the automobile coolant.

Embodiment 2

[0064] 2.1 Mix 20% of coolant 1,2-propylene glycol and 30.85% of deionized water in a blender, and stir evenly to obtain the first mixed liquid.

[0065] 2.2 The corrosion inhibitor isononanoic acid 2%, lauric acid 1%, benzotriazole 1%, triethanolamine 0.5% and preservatives 1,2-pentanediol 0.5%, 1,2-octyl glycol 0.5% , 0.1% ethylhexylglycerin and 2% emulsifier sodium lauroyl glutamate were vibrated in an ultrasonic wave to completely dissolve them in 15% dipropylene glycol to obtain a second mixed solution.

[0066] 2.3 Shake the anti-scaling agent 1% sodium polyepoxysuccinate, defoamer silicone polyether 0.5% and dyeing agent fluorescent violet 0.05% in the ultrasonic wave to completely dissolve them in 25% 1,3-propylene glycol, Obtain the third mixed solution.

[0067] 2.4 Pour the second mixed solution and the third mixed solution into the first mixed solution in sequence, and stir evenly to obtain the automobile coolant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com