Shock-proof self-cleaning impregnated paper and preparation method thereof

A self-cleaning, paper-impregnated technology, used in chemical instruments and methods, biocide-containing paints, paper/cardboard layered products, etc. Remove clean, easy to adhere stains and other problems, to achieve the effect of improving self-cleaning performance and stain resistance, not easy to separate between layers, not easy to damage or fall off in large areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

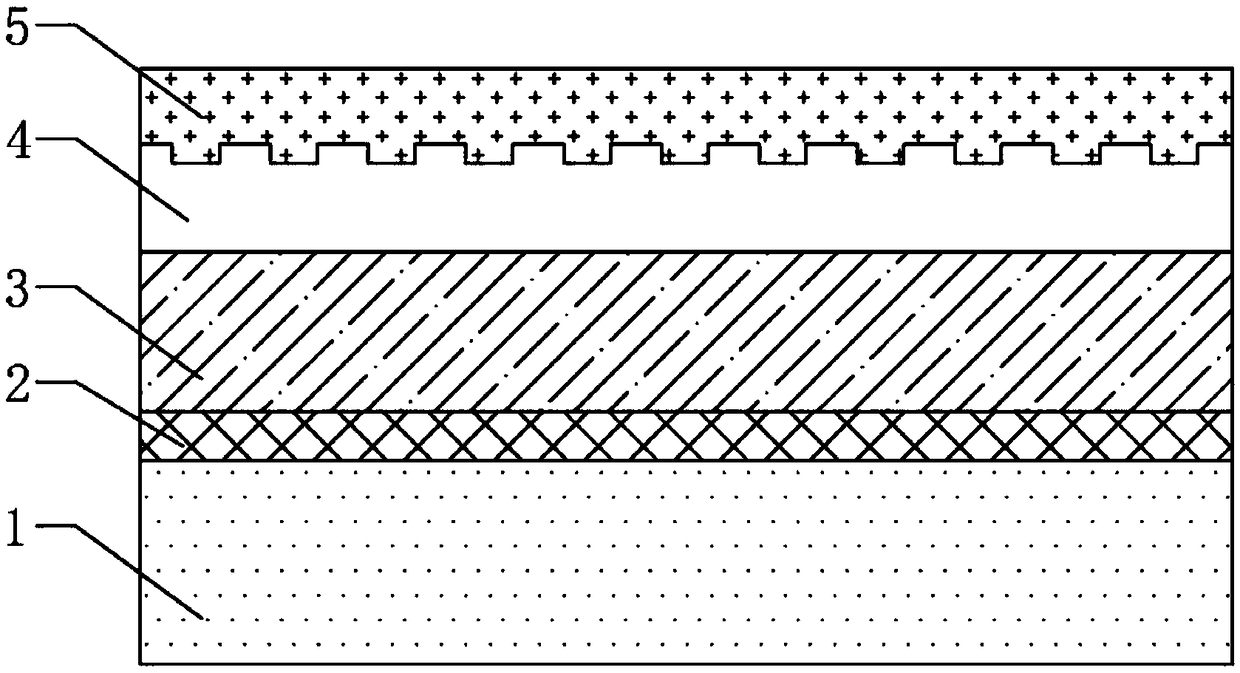

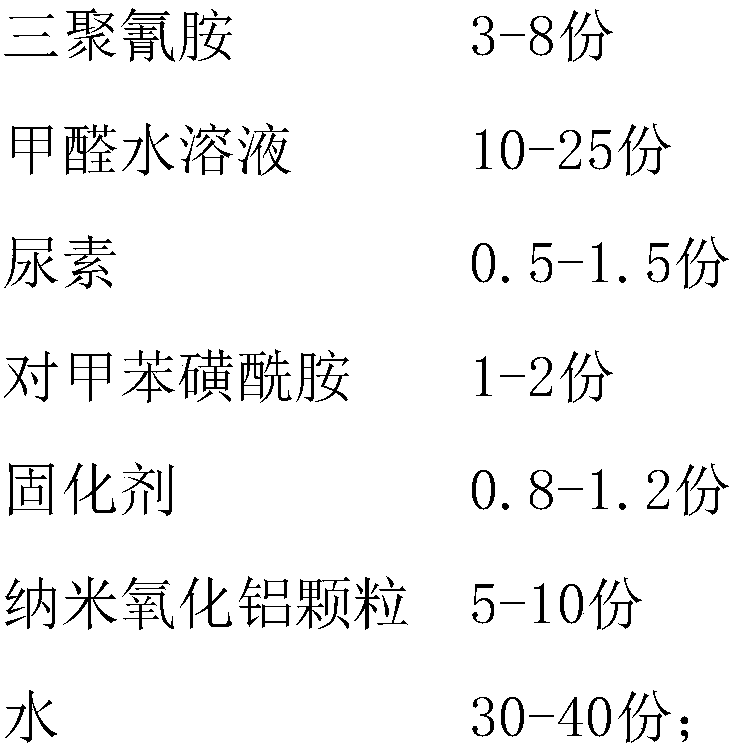

[0054] An impact-resistant self-cleaning impregnated paper, including a base paper layer 1, a hot-melt adhesive mesh layer 2, a printed texture layer 3, a wear-resistant adhesive layer 4, and nano TiO arranged sequentially from bottom to top 2 Self-cleaning layer 5, the mesh density of the hot melt adhesive mesh layer 2 is 100-130 / m 2 ; The wear-resistant adhesive layer 4 is made of melamine-formaldehyde composite glue; the nano-TiO 2 The self-cleaning layer 5 is made of nano-TiO 2 Made with self-cleaning paint.

Embodiment 2

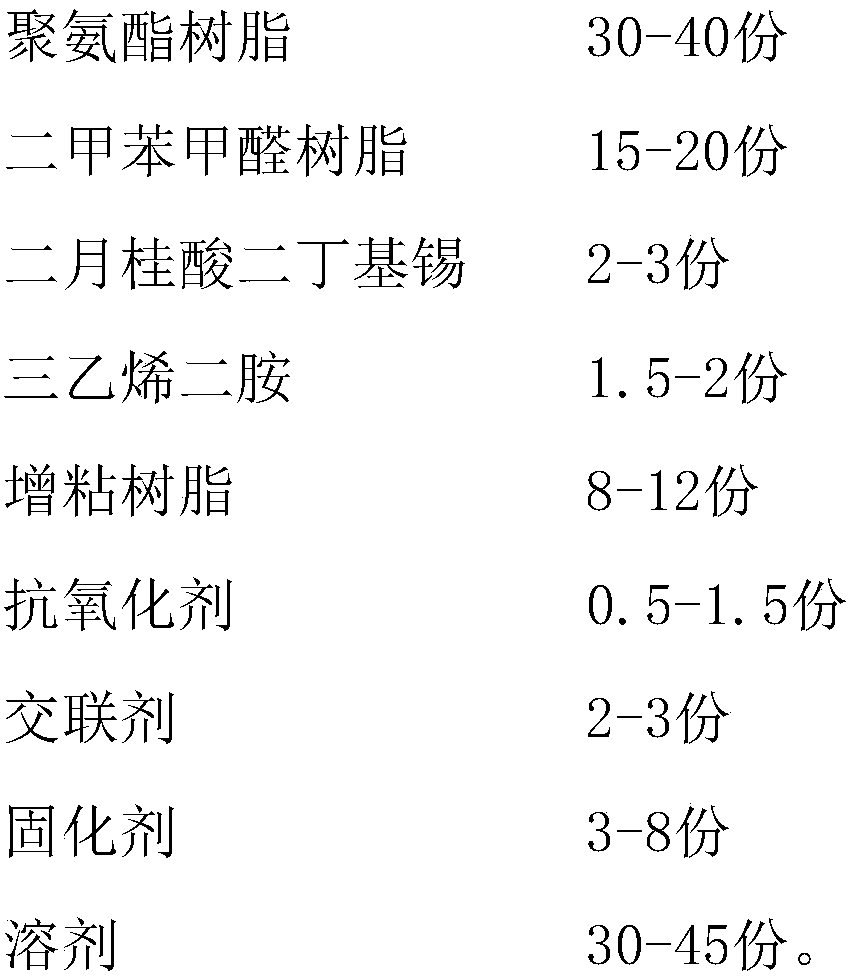

[0056] Described hot-melt adhesive network layer is made by polyurethane hot-melt adhesive, and described polyurethane hot-melt adhesive comprises the raw material of following weight portion:

[0057]

[0058] The tackifying resin is formed by mixing 2 parts of rosin glyceride and 1.5 parts of β-terpene resin; Acid] pentaerythritol ester, three [2.4-di-tert-butylphenyl] phosphite and didodecyl thiodipropionate acetone are the mixture that the weight ratio is 2:0.8:1 composition; The cross-linking agent consists of 3 parts of dicumyl peroxide and 1 part of diethylenetriamine are mixed; the curing agent is made of dodecenyl succinic anhydride and cyanoethylated diethylenetriamine in a weight ratio of 2:0.8 The mixture of composition; The solvent is a mixture of methyl acrylate and water in a weight ratio of 1.5:1.

[0059] Described polyurethane hot-melt adhesive is made by following steps:

[0060] (1) Add xylene formaldehyde resin to polyurethane resin, stir at 50°C for 40...

Embodiment 3

[0083] Described hot-melt adhesive network layer is made by polyurethane hot-melt adhesive, and described polyurethane hot-melt adhesive comprises the raw material of following weight portion:

[0084]

[0085] The tackifying resin is formed by mixing 2.5 parts of rosin glyceride and 1.8 parts of β-terpene resin; Acid] pentaerythritol ester, three [2.4-di-tert-butylphenyl] phosphite and didodecyl thiodipropionate acetone are the mixture that the weight ratio is 2.2:0.9:1 composition; The cross-linking agent consists of 3.2 parts of dicumyl peroxide and 1.5 parts of diethylenetriamine are mixed; the curing agent is 2.2:0.9 by weight ratio of dodecenyl succinic anhydride and cyanoethylated diethylenetriamine The mixture of composition; The solvent is a mixture of methyl acrylate and water in a weight ratio of 1.8:1.

[0086] Described polyurethane hot-melt adhesive is made by following steps:

[0087] (1) Add xylene formaldehyde resin to polyurethane resin, stir at 52°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com