Anode composition, method for preparing anode and lithium ion battery

A lithium-ion battery and composition technology, applied in negative electrodes, electrode manufacturing, secondary batteries, etc., can solve problems such as inability to improve cycle performance, and achieve the effect of easy implementation and non-toxic environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] Preparation method of negative electrode

[0072] There is no particular limitation on the preparation method of the negative electrode. In some embodiments, a method of preparing a negative electrode for a lithium-ion battery may include:

[0073] - preparation of a slurry by mixing all components of the negative electrode composition according to the invention with a solvent;

[0074] and

[0075] - applying said slurry on a current collector.

[0076] There is no particular limitation on the solvent used in the present invention, and known solvents in batteries can be used. In some embodiments, an inorganic solvent (such as water), an organic solvent (such as alcohol), or a combination thereof may be used as the solvent.

[0077] The entire method for preparing the negative electrode composition of the present invention is easy to implement, non-toxic and environmentally friendly.

[0079] A lithium-ion battery according to the ...

Embodiment 1

[0238] [Preparation of negative electrode]

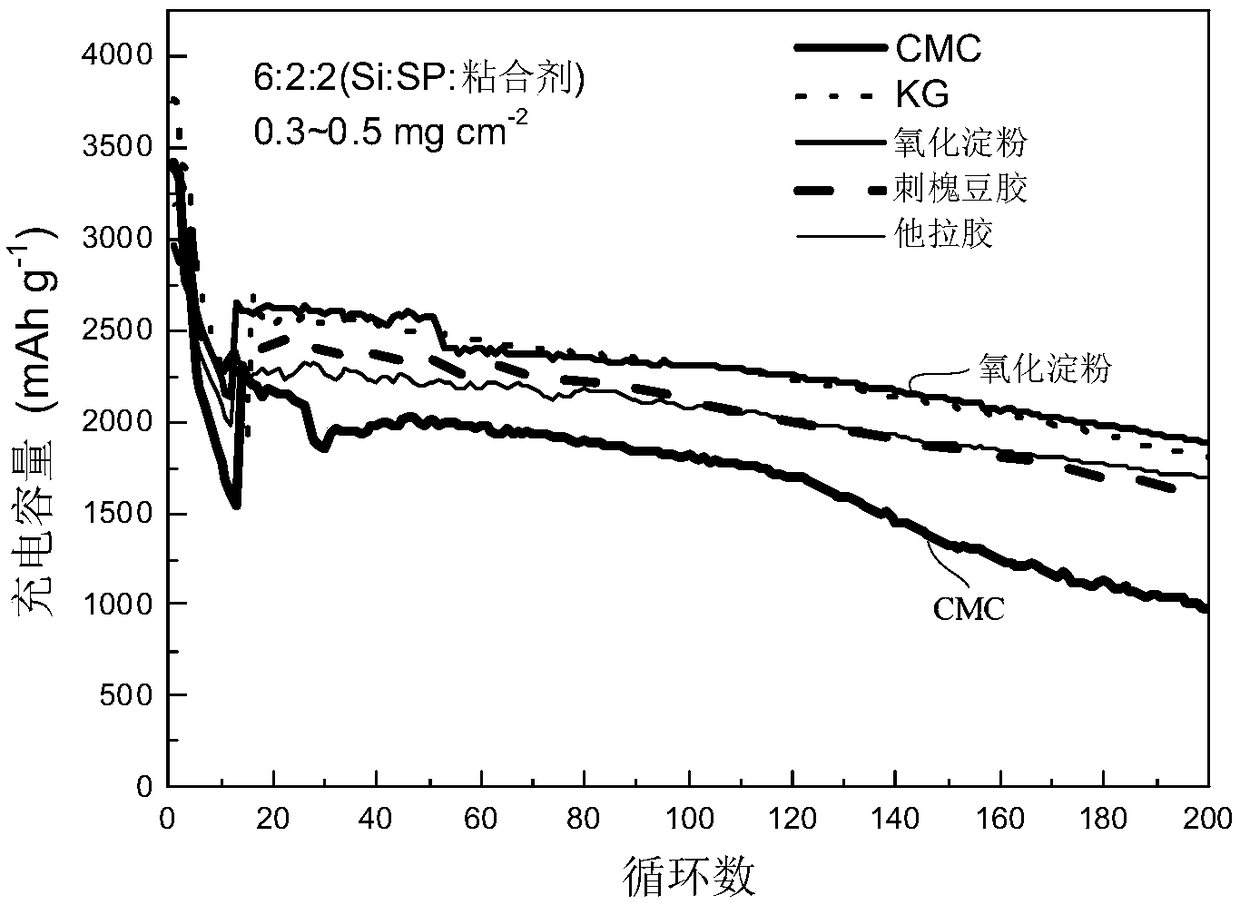

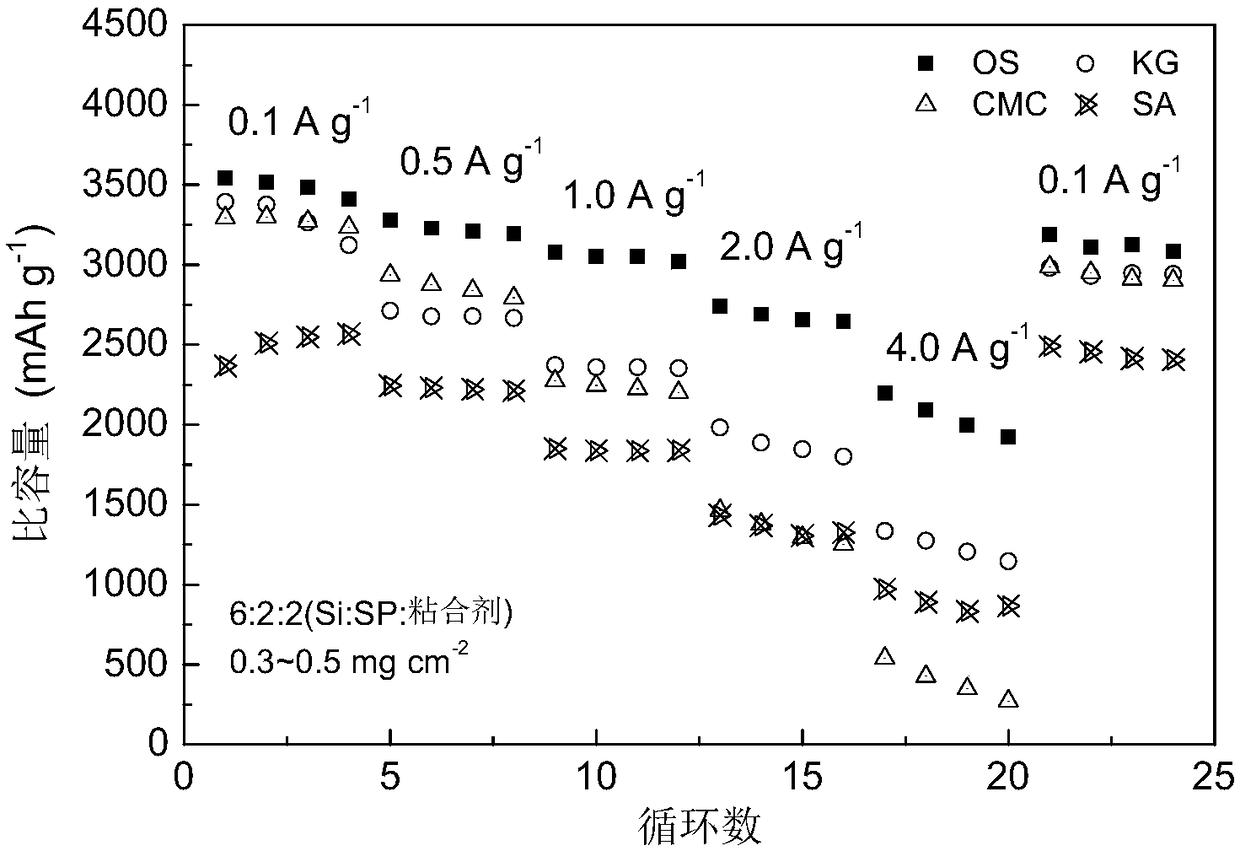

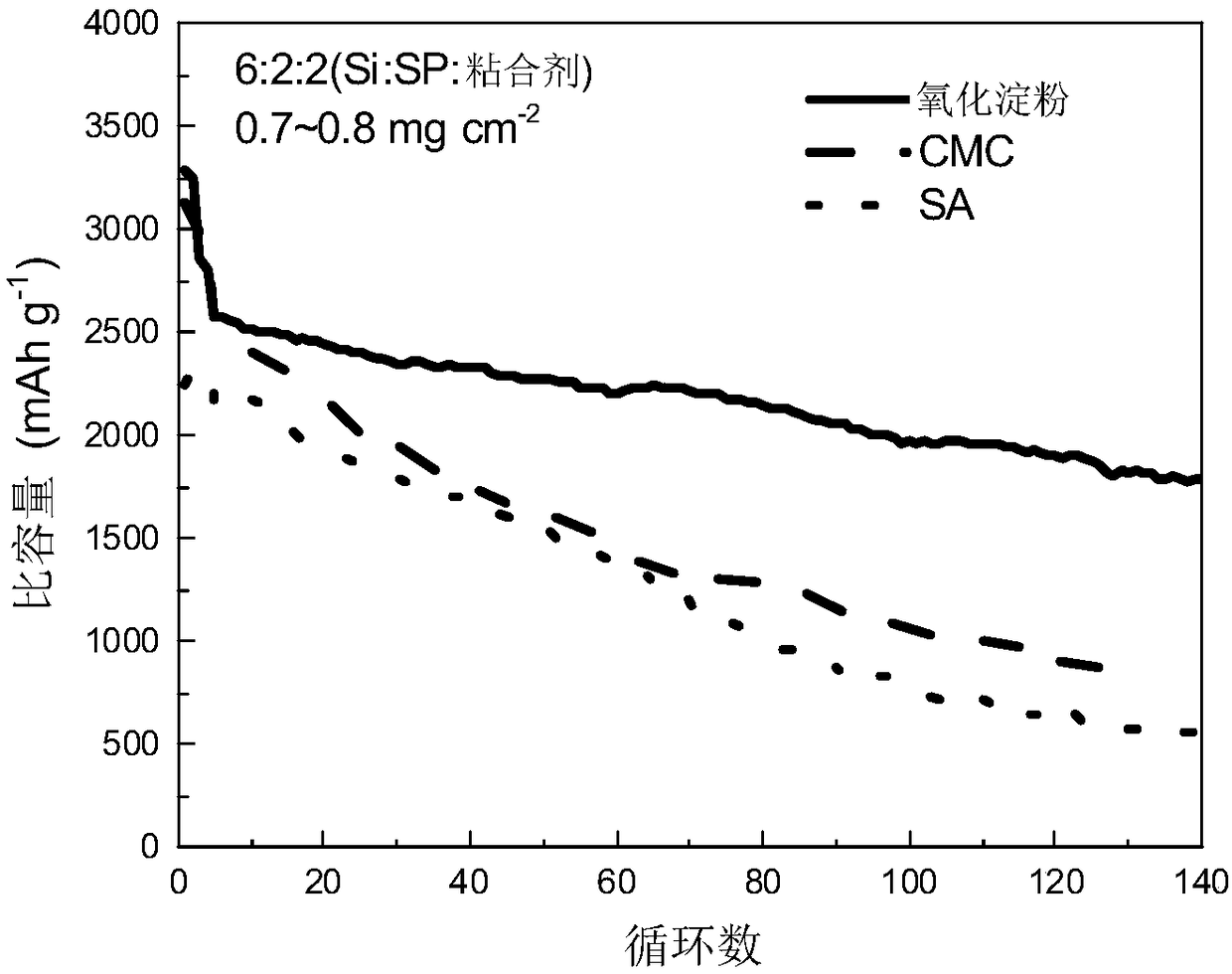

[0239] 600 mg of nano silicon particles were mixed with 200 mg of Super P (SP) and 200 mg of karaya gum (KG) in water to obtain a slurry. Here, the weight ratio of Si:SP:KG is 6:2:2. After stirring for 4 hours, the resulting slurry was coated on Cu foil and then dried in vacuum at 70 °C for 8 hours. Finally, the coated Cu foil was cut into several Φ12 mm anodes.

[0240] [Preparation of battery]

[0241] A coin cell (CR2016) was assembled in an argon-filled glove box (MB-10compact, MBraun) by using the negative electrode obtained as above. Li metal foil was used as a counter electrode. Use 1M LiPF in FEC / EC / DMC (1:5:5 volume ratio, mixture of fluoroethylene carbonate (FEC), ethylene carbonate (EC) and dimethyl carbonate (DMC)) 6 as an electrolyte. Use ET20-26 as the diaphragm.

Embodiment 2

[0243] The negative electrode and the battery were prepared in the same manner as described above for Example 1, except that 200 mg of oxidized starch (OS) was used instead of 200 mg of karat gum (KG).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com