Nickel-iron-based metal-organic framework materials rich in cyano vacancies, preparation methods and applications

A technology of organic frameworks and framework materials, applied in the field of nanomaterials, can solve problems such as unfavorable large-scale preparation and research of catalytic active sites, multiple structural components, and complex operation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present application also provides a method for preparing the nickel-iron-based metal-organic framework material rich in cyano vacancies, comprising the following steps:

[0041] A) NiMoO 4 The nanorod precursor is mixed with the iron cyanide complex solution, and after the reaction, a nickel-iron-based metal organic framework material is obtained, and the iron cyanide complex solution is potassium ferricyanide solution, sodium ferricyanide solution, ferrous Potassium cyanide solution or sodium ferrocyanide solution;

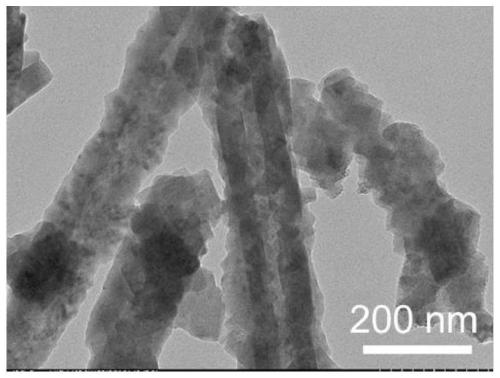

[0042] B) performing plasma bombardment on the nickel-iron-based metal-framed material to obtain a nickel-iron-based metal-organic framework material rich in cyano vacancies as shown in formula (I),

[0043] m 2 NiFe(CN) 6-x (I);

[0044] Wherein, M is K or Na;

[0045] x ranges from 0 to 0.5 and is not equal to 0.

[0046] In the process of preparing nickel-iron-based metal-organic framework materials rich in cyano vacancies, this application f...

Embodiment 1

[0062] (1)NiMoO 4 Preparation of nanorod precursor: Weigh 2mmol nickel nitrate and 2mmol sodium molybdate, and dissolve them in 17.5ml deionized water respectively; add the above-mentioned nickel nitrate solution into the sodium molybdate solution, and stir for 10 minutes to form a uniform mixed solution; Transfer the mixed solution to a 45ml reaction kettle, put it into a 150°C oven for 6 hours; take out the reaction kettle, find a large amount of precipitation, centrifuge and wash with deionized water and ethanol, and dry in a vacuum oven at 60°C for 12 hours to obtain NiMoO 4 Nanorod precursors;

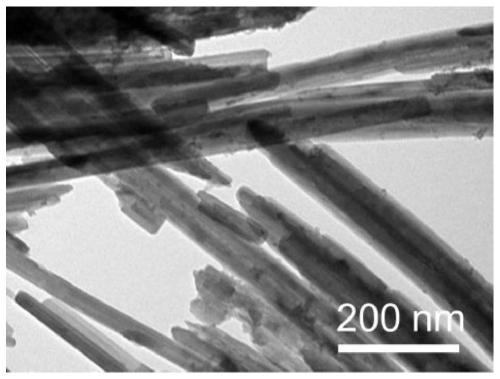

[0063] (2) Preparation of nickel-iron-based metal-organic framework materials: Dissolve 120 mg of potassium ferrocyanide in 30 mL of deionized water, stir to fully dissolve; dissolve 40 mg of the above-mentioned NiMoO 4 The nanorod precursor was added to the potassium ferrocyanide solution, stirred at room temperature for 3 hours, centrifuged and washed with deionized water and e...

Embodiment 2

[0067] The same preparation method as in Example 1, except that the plasma bombardment time in the above step (3) was changed to 10 min.

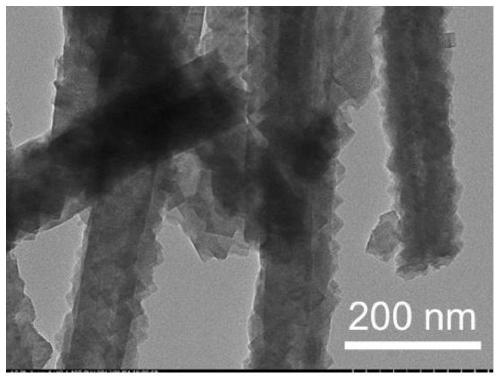

[0068] Gained sample is carried out transmission electron microscope analysis, the result sees Figure 5 , The product has a porous rod-like structure with a diameter of 80-140nm. It can be seen that shortening the bombardment time of the plasma does not affect the morphology of the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com