A kind of anti-cracking cement pipe pile for photovoltaic and preparation method thereof

A cement pipe and photovoltaic technology, which is applied in clay preparation devices, cement mixing devices, chemical instruments and methods, etc., can solve the problems of low bearing capacity, easy cracking, and poor pile quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

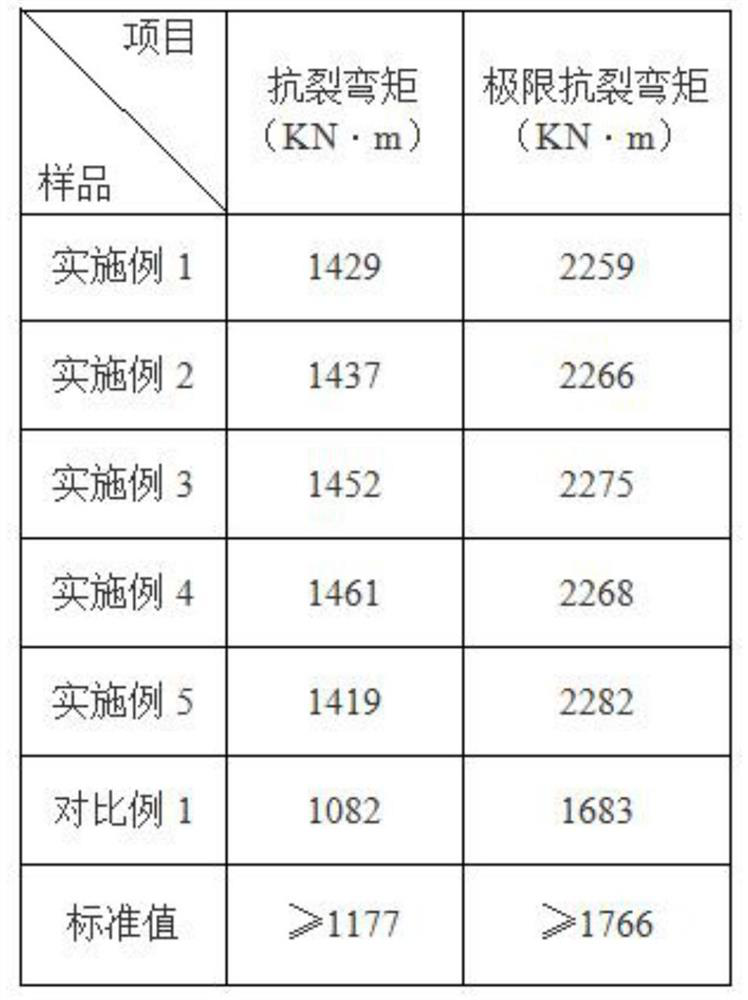

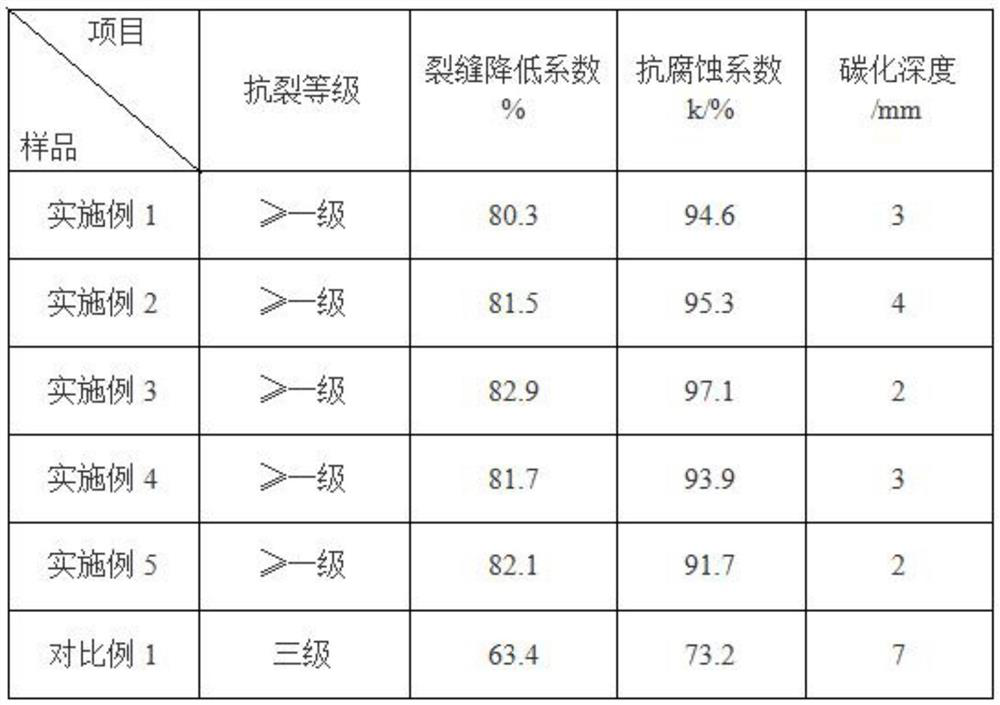

Examples

Embodiment 1

[0041] An anti-cracking cement pipe pile for photovoltaic use, the anti-cracking cement pipe pile includes the following components in parts by weight: 250 parts of sand with a particle size of 5 mm, 120 parts of quartz sand with a particle size of 0.1 mm, and a strength grade of 200 parts of ordinary portland cement of grade 32.5, 50 parts of admixture, 10 parts of admixture, 5 parts of anti-cracking component and 150 parts of water.

[0042] The anti-crack component in the above raw materials is a mixture of glass fiber, polypropylene fiber and metal fiber, the mass ratio of glass fiber, polypropylene fiber and metal fiber is 1:2:1, the length of the metal fiber is 1mm, and the diameter is 0.1mm , the glass fiber has a length of 3mm and a diameter of 0.1mm, and the polypropylene fiber has a length of 1mm and a diameter of 0.1mm.

[0043] The admixture in the above raw materials is a mixture of limestone powder, silicon powder and steel slag powder, the mass ratio of limeston...

Embodiment 2

[0052] An anti-cracking cement pipe pile for photovoltaic use, the anti-cracking cement pipe pile includes the following components in parts by weight: 280 parts of sand with a particle size of 8 mm, 125 parts of quartz sand with a particle size of 1 mm, and a strength grade of 42.5 250 parts of ordinary portland cement, 60 parts of admixture, 13 parts of admixture, 8 parts of anti-cracking component and 180 parts of water.

[0053] The anti-crack component in the above raw materials is a mixture of glass fiber, polypropylene fiber and metal fiber, the mass ratio of glass fiber, polypropylene fiber and metal fiber is 1:2.5:1-2, the length of the metal fiber is 2mm, the diameter The length of the glass fiber is 4mm and the diameter is 0.12mm, and the length of the polypropylene fiber is 3mm and the diameter is 0.15mm.

[0054] The admixture in the above raw materials is a mixture of granite stone powder, silicon powder and steel slag powder, the mass ratio of granite stone powd...

Embodiment 3

[0063] An anti-cracking cement pipe pile for photovoltaic use, the anti-cracking cement pipe pile includes the following components in parts by weight: 365 parts of sandstone with a particle size of 17.5mm, 135 parts of quartz sand with a particle size of 2.3mm, strength grade It is 300 parts of 32.5 grade ordinary portland cement, 75 parts of admixture, 20 parts of admixture, 12.5 parts of anti-cracking component and 250 parts of water.

[0064] The anti-crack component in the above raw materials is a mixture of glass fiber, polypropylene fiber and metal fiber, the mass ratio of glass fiber, polypropylene fiber and metal fiber is 1:3.5:1.5, the length of the metal fiber is 5.5mm, and the diameter is 0.2mm, the glass fiber is 6.5mm in length and 0.15mm in diameter, and the polypropylene fiber is 8mm in length and 0.2mm in diameter.

[0065] The admixture in the above raw materials is a mixture of quartz rock powder, silicon powder and steel slag powder, the mass ratio of quart...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com