Phase change heat storage material, phase change heat storage brick and preparation method thereof

A phase change heat storage material and phase change material technology, applied in the field of phase change heat storage bricks and its preparation, and phase change heat storage materials, can solve the problems of low heat storage density and poor thermal stability, and achieve high energy storage density , enhanced thermal stability, easy operation control and management effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

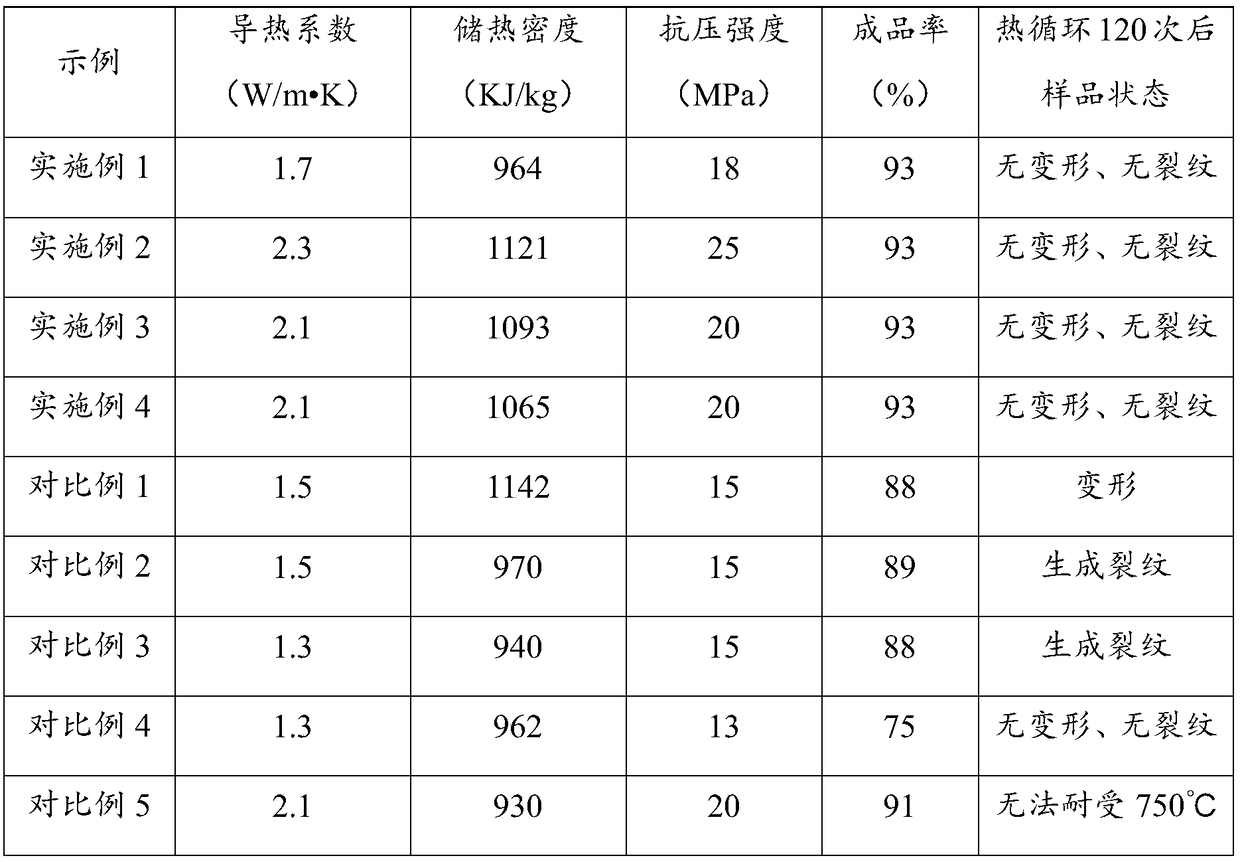

Examples

Embodiment 1

[0034] This embodiment provides a phase change heat storage brick and its preparation method, the preparation method of the phase change heat storage brick includes the following steps:

[0035] MgO with a particle size of 50 μm and magnesia (MS-96) with a particle size of 0.1 mm (MS-96) were selected and mixed uniformly at a mass ratio of 7:3 to obtain a skeleton material for subsequent use; Na 2 CO 3 and K 2 CO 3 Mix evenly according to the mass ratio of 52.2:47.8 to obtain the phase change material for later use; the polyvinyl alcohol aqueous solution and kaolin are respectively weighed according to the mass ratio of 3:7, and for later use; wherein, the mass ratio of the skeleton material, the phase change material and the binder is 59:40 :1.

[0036] Add the skeleton material, phase change material and sodium silicate into the mixer in sequence, and the mixing time is 30 minutes; add them into the kneader, and at the same time add a polyvinyl alcohol aqueous solution wi...

Embodiment 2

[0038] This embodiment provides a phase change heat storage brick and its preparation method, the preparation method of the phase change heat storage brick includes the following steps:

[0039] Select MgO with a particle size of 30 μm and MS-96 with a mass ratio of 9:1 to mix uniformly to obtain a skeleton material for subsequent use; Li 2 CO 3 、Na 2 CO 3 and K 2 CO 3 Mix uniformly by mass ratio 4.4:45:50.6 to obtain phase change material for subsequent use; polyvinyl alcohol aqueous solution, borax and sodium silicate are weighed respectively by mass ratio 5:3:2, wherein borax and sodium silicate are mixed uniformly for subsequent use; , the mass ratio of skeleton material, phase change material and binder is 32:60:8.

[0040] Add the skeleton material, phase change material and sodium silicate into the mixer in turn, and the mixing time is 60 minutes; add them into the kneader, and at the same time add polyvinyl alcohol with a mass fraction of 7%, knead for 20 minutes, a...

Embodiment 3

[0042] This embodiment provides a phase change heat storage brick and its preparation method, the preparation method of the phase change heat storage brick includes the following steps:

[0043] MgO with a particle size of 40 μm and MS-96 with a particle size of 0.5 mm were selected and mixed uniformly at a mass ratio of 9:1 to obtain a skeleton material for subsequent use; Li 2 CO 3 、Na 2 CO 3 and K 2 CO 3 Mix evenly according to the mass ratio 2.2:48.6:49.2 to obtain the phase change material for subsequent use; the polyvinyl alcohol aqueous solution and borax are respectively weighed according to the mass ratio of 4:6 for subsequent use; wherein, the mass ratio of the skeleton material, the phase change material and the binder is 32 :60:8.

[0044] Add the skeleton material, phase change material and sodium silicate into the mixer in turn, and the mixing time is 40 minutes; add them into the kneader, and at the same time add polyvinyl alcohol with a mass fraction of 3%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com