Method for comprehensive utilization of wood fiber all components

A wood fiber, full-component technology, applied in fiber raw material processing, textile and paper making, etc., to achieve the effect of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) CO 2 Auxiliary hydrothermal liquefaction process:

[0030] Weigh 8g of poplar sawdust and mix 80g of water into the autoclave, and feed CO 2 Gas 20bar, start stirring, raise the temperature to 140°C at a heating rate of 5°C / min, keep it warm for 10min, cool down to room temperature quickly after the reaction, filter, wash the residue with water, and dry at 105°C to obtain 6.82g of solid residue, transform The rate is 17.73%. The yield of C5 sugar and C5 sugar derivatives was 10.74%. The contents of cellulose, hemicellulose and lignin in the residue were 54.79%, 15.60% and 24.43%, respectively.

[0031] (2) Catalytic hydrogenation process:

[0032] Get the solid residue after drying in the above step (1), catalyst 3.41g, solvent is isopropanol and water (2: 1, v / v), join reaction kettle, wherein solid residue: mixed solvent=1: 10 ( w / w), and pass through 40barH 2 , the temperature was raised to 220°C, and the reaction time was 6h. After the reaction kettle is ...

Embodiment 2

[0036] (1) CO 2 Auxiliary hydrothermal liquefaction process:

[0037] Weigh 8g of poplar sawdust and mix 80g of water into the autoclave, and feed CO 2 Gas 20bar, start stirring, raise the temperature to 160°C at a heating rate of 5°C / min, keep it warm for 10min, cool down to room temperature quickly after the reaction, filter, wash the residue with water, and dry at 105°C to obtain 5.97g of solid residue, transform The rate is 25.41%. The yield of C5 sugar and C5 sugar derivatives was 12.65%. The contents of cellulose, hemicellulose and lignin in the residue were 60.36%, 8.23%, and 26.26%, respectively.

[0038] (2) Catalytic hydrogenation process:

[0039] Get the solid residue obtained in the above step (1), catalyst 2.99g, mixed solvent isopropanol and water (2:1, v / v) into the reactor, wherein solid residue: mixed solvent=1:10 (w / w ), and pass into 40bar H 2 , the temperature was raised to 220°C, and the reaction time was 6h. After the reaction kettle is cooled dow...

Embodiment 3

[0043] (1) CO 2 Auxiliary hydrothermal liquefaction process:

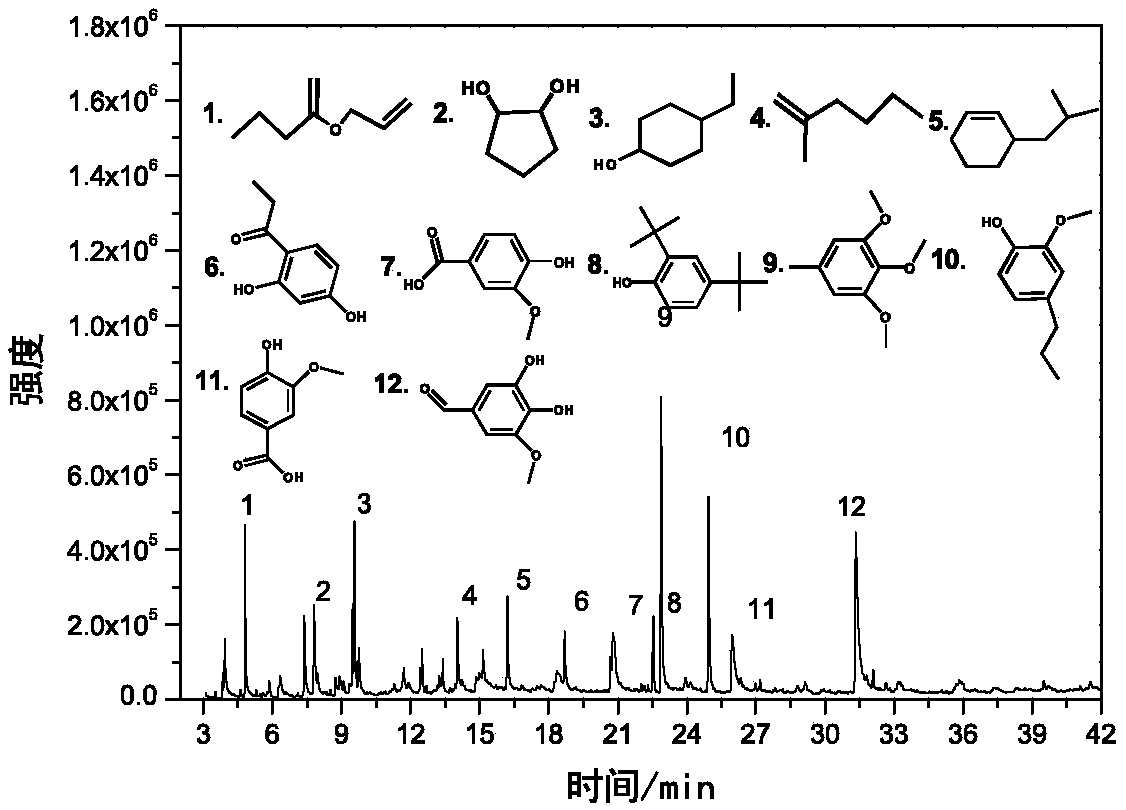

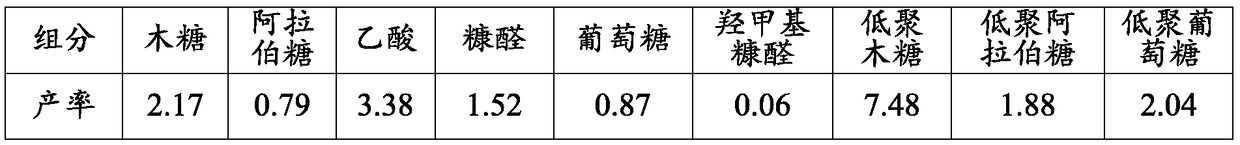

[0044] Weigh 8g of poplar sawdust and mix 80g of water into the autoclave, and feed CO 2 Gas 20bar, start stirring, raise the temperature to 180°C at a heating rate of 5°C / min, keep it warm for 10min, cool down to room temperature quickly after the reaction, filter, wash the residue with water, and dry at 105°C to obtain 5.12g of solid residue, transform The rate is 35.05%. The yield of C5 sugar and C5 sugar derivatives was 17.22%. The contents of cellulose, hemicellulose and lignin in the residue were 66.42%, 3.97%, and 24.20%, respectively. The liquid product was subjected to liquid phase test and analysis, and the test results are shown in Table 1. It can be seen from Table 1 that the main components of the liquid products of carbon dioxide assisted liquefaction are xylooligosaccharides, arabinose oligosaccharides, glucose oligosaccharides xylose, arabinose, acetic acid, furfural, glucose and hydroxymethylfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com