A kind of method for removing tellurium in coarse selenium slag

A crude selenium, primary technology, applied in the field of crude selenium slag purification, can solve the problems of not being able to produce qualified selenium products and high tellurium content of selenium products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

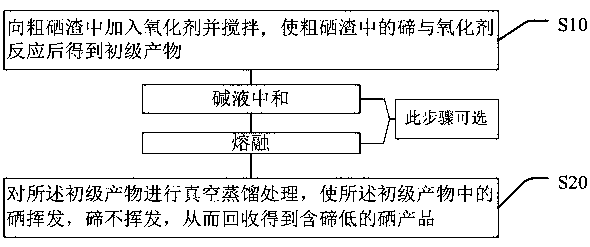

Method used

Image

Examples

Embodiment 1

[0034] 1. Oxidation of crude selenium slag: add 30% hydrogen peroxide to tap water to dilute it into a 15% hydrogen peroxide solution, then add the hydrogen peroxide solution to the coarse selenium slag and stir. The tellurium content in the thick selenium slag is 1.57%. According to the reaction of the amount of tellurium contained in the thick selenium slag with the oxidizing agent, the ratio of the required oxidizing agent is calculated, and the concentration of 6% of the thick selenium slag weight is 15% hydrogen peroxide added to the crude selenium slag. In the selenium slag, stir it to make it mix evenly, and the oxidation reaction of tellurium occurs; then add NaOH to the solution for neutralization, and adjust the pH value to 5;

[0035] 2. The material after the oxidation reaction is melted: the material obtained in step 1 is added to the heating container, and heated to 260°C to melt it. After melting, the form of selenium remains unchanged, while the form of telluriu...

Embodiment 2

[0038] 1. Oxidation of crude selenium slag: add 30% hydrogen peroxide to tap water to dilute it into a 15% hydrogen peroxide solution, then add the hydrogen peroxide solution to the coarse selenium slag and stir. The tellurium content in the thick selenium slag is 1.57%. According to the reaction of the amount of tellurium contained in the thick selenium slag with the oxidizing agent, the ratio of the required oxidizing agent is calculated, and the concentration of 7% of the thick selenium slag weight is 15% hydrogen peroxide added to the crude selenium slag. In the selenium slag, stir it to make it mix evenly, and the oxidation reaction of tellurium occurs; then add KOH to the solution for neutralization, and adjust the pH value to 6;

[0039] 2. The material after the oxidation reaction is melted: the material obtained in step 1 is added to a heating container, and heated to 280°C to melt it. After melting, the form of selenium remains unchanged, while the form of tellurium c...

Embodiment 3

[0042]1. Oxidation of crude selenium slag: Add 30% hydrogen peroxide to tap water to dilute it into a 20% hydrogen peroxide solution, then add the hydrogen peroxide solution to the coarse selenium slag and stir. The tellurium content in the thick selenium slag is 1.57%. According to the reaction of the amount of tellurium contained in the thick selenium slag with the oxidizing agent, the ratio of the required oxidizing agent is calculated, and the concentration of 5% of the thick selenium slag weight is 20% hydrogen peroxide added to the crude selenium slag. In the selenium slag, stir it to make it mix evenly, and the oxidation reaction of tellurium occurs; then add NaOH to the solution for neutralization, and adjust the pH value to 6;

[0043] 2. The material after the oxidation reaction is melted: the material obtained in step 1 is added to the heating container, and heated to 240°C to melt it. After melting, the form of selenium remains unchanged, while the form of tellurium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com