PTFE (polytetrafluoroethylene)-based microwave composite dielectric substrate and preparation method thereof

A composite medium and microwave technology, which is applied in the field of PTFE-based microwave composite medium substrate and its preparation, can solve the problems of small dielectric loss and the inability of microwave composite medium substrate to satisfy high dielectric constant at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing a PTFE-based microwave composite dielectric substrate, comprising the following steps:

[0030] Provide high dielectric perovskite ceramics;

[0031] mixing the high-intermediate perovskite ceramics with polytetrafluoroethylene to obtain an organic-inorganic blend;

[0032] Molding the organic-inorganic blend to obtain a composite material pre-pressed tablet;

[0033] The composite material pre-pressed sheet is vacuum hot-pressed to obtain a PTFE-based microwave composite dielectric substrate.

[0034] The invention provides high dielectric perovskite ceramics. The present invention preferably adopts the solid phase synthesis method to prepare the high dielectric perovskite type ceramics. In the present invention, the solid-phase synthesis method preferably includes high-temperature sintering, the temperature of the high-temperature sintering is preferably 1100° C., and the time is preferably 12 hours.

[0035] After the...

Embodiment 1

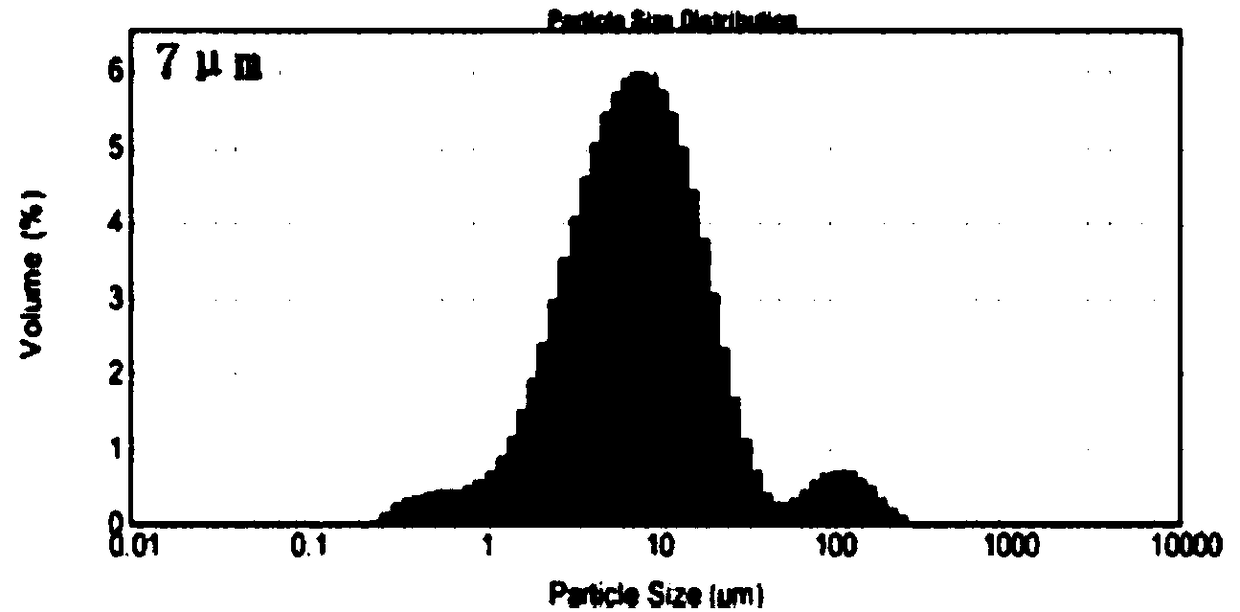

[0045] The high-dielectric perovskite-type ceramic powder prepared by the solid-phase synthesis method is pulverized and particle size controlled by jet milling to obtain an inorganic high-dielectric perovskite-type ceramic filler with D50 of 7 μm and uniform particle size distribution; the high-dielectric perovskite type ceramic filler is obtained. Dielectric constant ε of mineral ceramic powder r is 105, the dielectric loss tgδ is less than 5×10 -3 , ε r The absolute value of the temperature coefficient is less than 30ppm / ℃;

[0046] The particle size of the polytetrafluoroethylene resin powder is controlled by jet milling to obtain an organic polytetrafluoroethylene resin filler with a D50 of 10 μm and a uniform particle size distribution;

[0047] Mix the ceramic powder and the polytetrafluoroethylene resin powder in a double-center mixer at a mass ratio of 1:1 to obtain a uniform blend of the filler and the matrix;

[0048] The above mixture is evenly spread in the mol...

Embodiment 2

[0057] The high-dielectric perovskite-type ceramic powder prepared by the solid-phase synthesis method is pulverized and particle size controlled by jet milling to obtain an inorganic high-dielectric perovskite-type ceramic filler with a D50 of 7 μm and a uniform particle size distribution; the high-dielectric perovskite type ceramic filler; Dielectric constant ε of mineral ceramic powder r is 105, the dielectric loss tgδ is less than 5×10 -3 , ε r The absolute value of the temperature coefficient is less than 30ppm / ℃;

[0058] The particle size of the polytetrafluoroethylene resin powder is controlled by jet milling to obtain an organic polytetrafluoroethylene resin filler with a D50 of 10 μm and a uniform particle size distribution;

[0059] Mix the ceramic powder and the polytetrafluoroethylene resin powder in a double-center mixer at a mass ratio of 3:2 to obtain a uniform blend of the filler and the matrix;

[0060] The above mixture is evenly spread in the mold, and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com