High-wear-resistance TPU/silica gel composite material and preparation method thereof

A composite material, silica gel technology, applied in antifouling/underwater coatings, chemical instruments and methods, polyurea/polyurethane coatings, etc. High resistance, high wear resistance and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A kind of TPU / silica gel composite material, comprises the 1.5mm thick base cloth layer microfiber nonwoven fabric of stacking successively (weight per unit area is 200g / m 2 ), a 0.15mm thick first hot melt adhesive layer, a 0.05mm thick TPU layer, a 0.03mm thick second hot melt adhesive layer and a 0.05mm thick silicone layer.

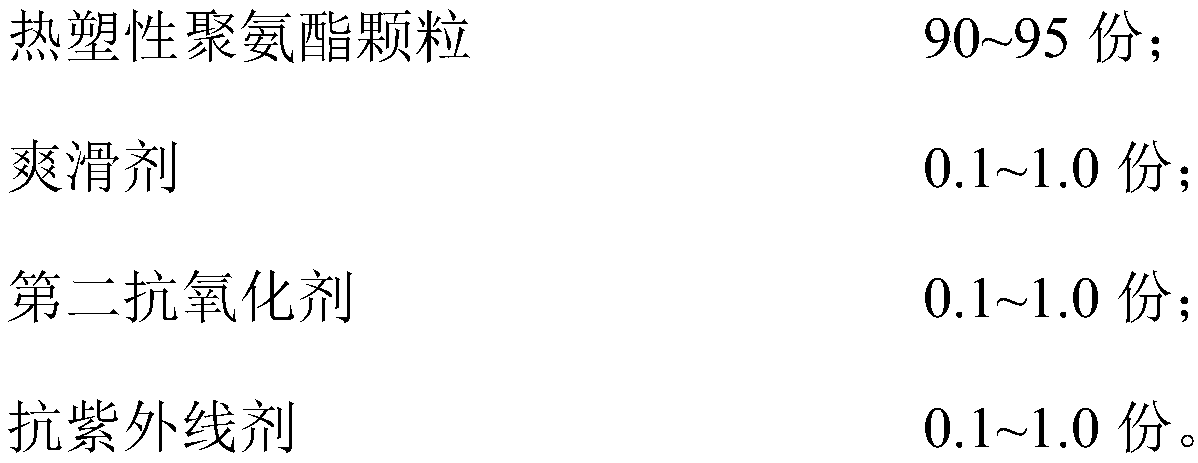

[0060] The preparation raw material of described TPU hot-melt adhesive layer comprises following raw material component by weight part:

[0061]

[0062] The preparation method of the polyester polyol is as follows: mix 1 mol of sebacic acid, 2.5 mol of terephthalic acid and 4.0 mol of ethylene glycol, then add 0.003 mol of isopropyl zirconate, heat up to 160°C for polycondensation reaction to obtain decane Diacid polyester polyol (weight average molecular weight 1500);

[0063] The flame retardant comprises by weight percentage: 30wt% dimethyl phosphite, 35wt% ammonium polyphosphate, 35wt% pentaerythritol;

[0064] The preparation method ...

Embodiment 2

[0071] A kind of TPU / silica gel composite material, comprises the 3.0mm thick base fabric layer superfine fiber non-woven fabric (unit area weight is 400g / m2) of stacking successively 2 ), a 0.11mm thick first hot melt adhesive layer, a 0.01mm thick TPU layer, a 0.02mm thick second hot melt adhesive layer and a 0.01mm thick silicone layer.

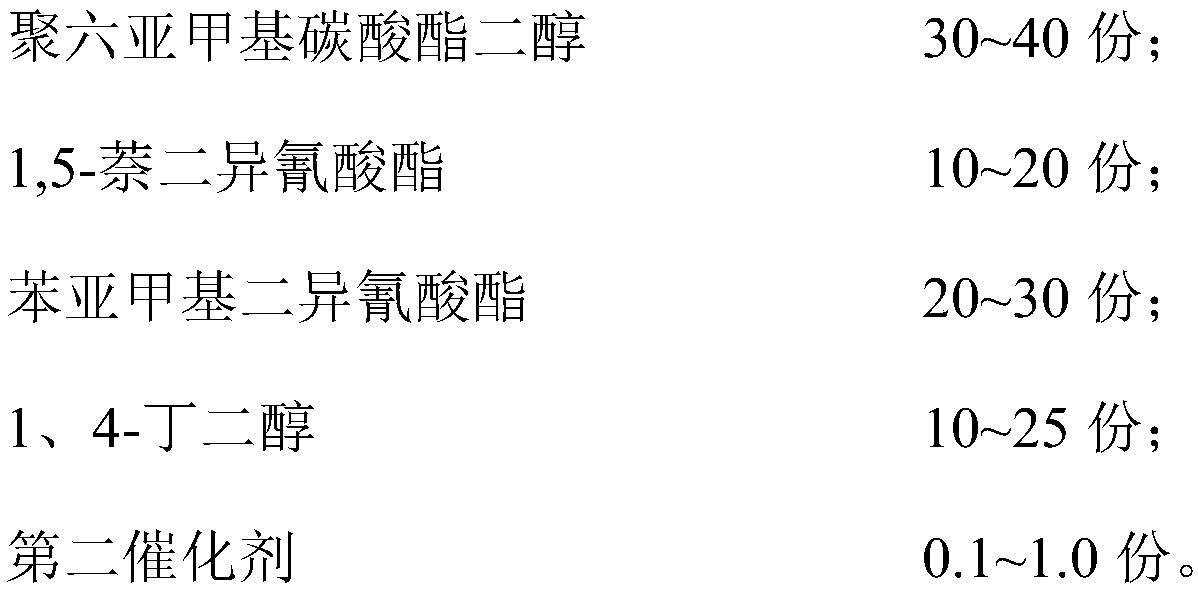

[0072] The preparation raw material of described TPU hot-melt adhesive layer comprises following raw material component by weight part:

[0073]

[0074] The preparation method of the polyester polyol is as follows: mix 1 mol of sebacic acid, 2.5 mol of terephthalic acid and 4.0 mol of ethylene glycol, then add 0.003 mol of isopropyl zirconate, heat up to 200°C for polycondensation reaction to obtain decane Diacid polyester polyol (weight average molecular weight 2000);

[0075] The flame retardant comprises by weight percentage: 20wt% dimethyl phosphite, 40wt% ammonium polyphosphate, 40wt% pentaerythritol;

[0076] The preparation me...

Embodiment 3

[0083] A kind of TPU / silica gel composite material, comprises successively laminated 0.1mm thick base cloth layer superfine fiber non-woven fabric (weight per unit area is 200g / m 2 ), a 0.20mm thick first hot melt adhesive layer, a 0.08mm thick TPU layer, a 0.05mm thick second hot melt adhesive layer and a 0.10mm thick silicone layer.

[0084] The preparation raw material of described TPU hot-melt adhesive layer comprises following raw material component by weight part:

[0085]

[0086] The preparation method of the polyester polyol is as follows: mix 1 mol of sebacic acid, 2.5 mol of terephthalic acid and 4.0 mol of ethylene glycol, then add 0.003 mol of isopropyl zirconate, heat up to 160°C for polycondensation reaction to obtain decane Diacid polyester polyol (weight average molecular weight 1500);

[0087] The flame retardant comprises by weight percentage: 25wt% dimethyl phosphite, 35wt% ammonium polyphosphate, 35wt% pentaerythritol;

[0088]The preparation method o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com