Polymeric phosphorus-nitrogen-silicon flame retardant as well as synthesis method and application thereof

A synthesis method, the technology of phosphorus nitrogen and silicon, which is applied in the field of flame retardants, can solve the problems such as the absence of polymeric phosphorus nitrogen and silicon flame retardants, and achieve the effects of excellent flame retardancy and improved impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

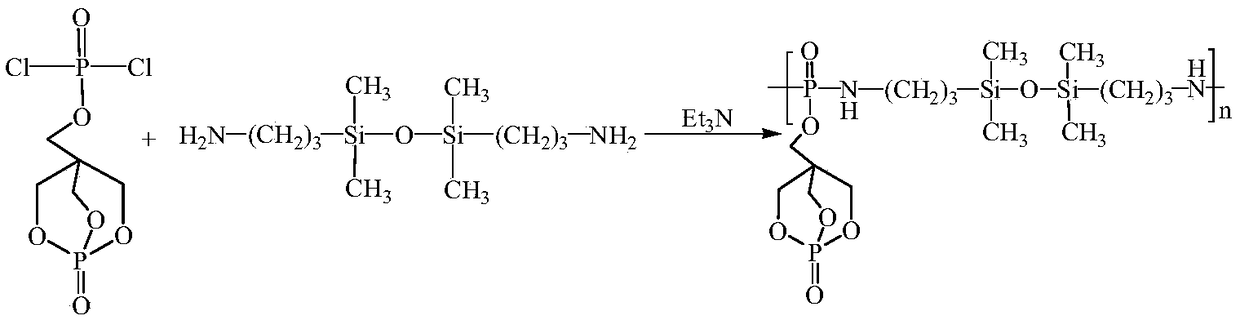

[0031] Step 1: the synthesis of PEPA, the synthetic route is as follows:

[0032]

[0033] Specifically: add 0.50 mol of pentaerythritol and 240 mL of 1,4-dioxane into a 500 mL four-necked flask equipped with nitrogen protection, a mechanical stirrer, a thermometer, a spherical condenser, and a tail gas absorption device. Access to N 2 , heated and stirred to raise the temperature to 70°C. When the temperature of the reaction system rose to 70°C and the pentaerythritol was partially dissolved, 0.55mol of phosphorus oxychloride was started to be added dropwise, and the dropwise addition was completed within 2 hours. After the dropwise addition, keep warm for 20 minutes, then raise the temperature until the system refluxes, keep warm for 6 hours, until no obvious white smoke is produced in the tail gas absorption device. After the reaction was completed, it was allowed to stand overnight, filtered with suction, and the filter cake was washed twice with solvents 1,4-dioxane a...

Embodiment 2

[0041] This example is basically the same as Example 1, except that the molar ratio of PDCP to 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane is 0.8: 1. The final yield was 83%, lower than Example 1.

Embodiment 3

[0047] 1. Use the SX2-25-10 box-type resistance furnace produced by Shanghai Experimental Instrument Factory to test the sample, dry the PNSFR in the oven at 100°C for about 2 hours, and then accurately weigh 1.0g of PNSFR with an analytical balance and put it Put the crucible into the crucible, put the crucible into a box-type resistance furnace for calcination at 500°C for 30 minutes, take it out after cooling, use an analytical balance to accurately measure the expansion volume and carbon residue after calcination, and finally calculate the expansion degree and carbon residue by calculation formula quantity. The calculation formula is as follows:

[0048]

[0049]

[0050] The above are the calculation formulas of expansion degree and carbon residue amount, where ID and R are expansion degree and carbon residue rate respectively, ΔV is the volume change of the sample before and after calcination, M is the product quality before calcination, and m is the product qualit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com