High-heat-conducting and flame-retardant polyethylene-based composite material and preparation method thereof

A technology of flame retardant polyethylene and composite materials, which is applied in heat exchange materials, chemical instruments and methods, plastic/resin/wax insulators, etc. The effect of thermal conductivity, extended service life and large breakdown field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

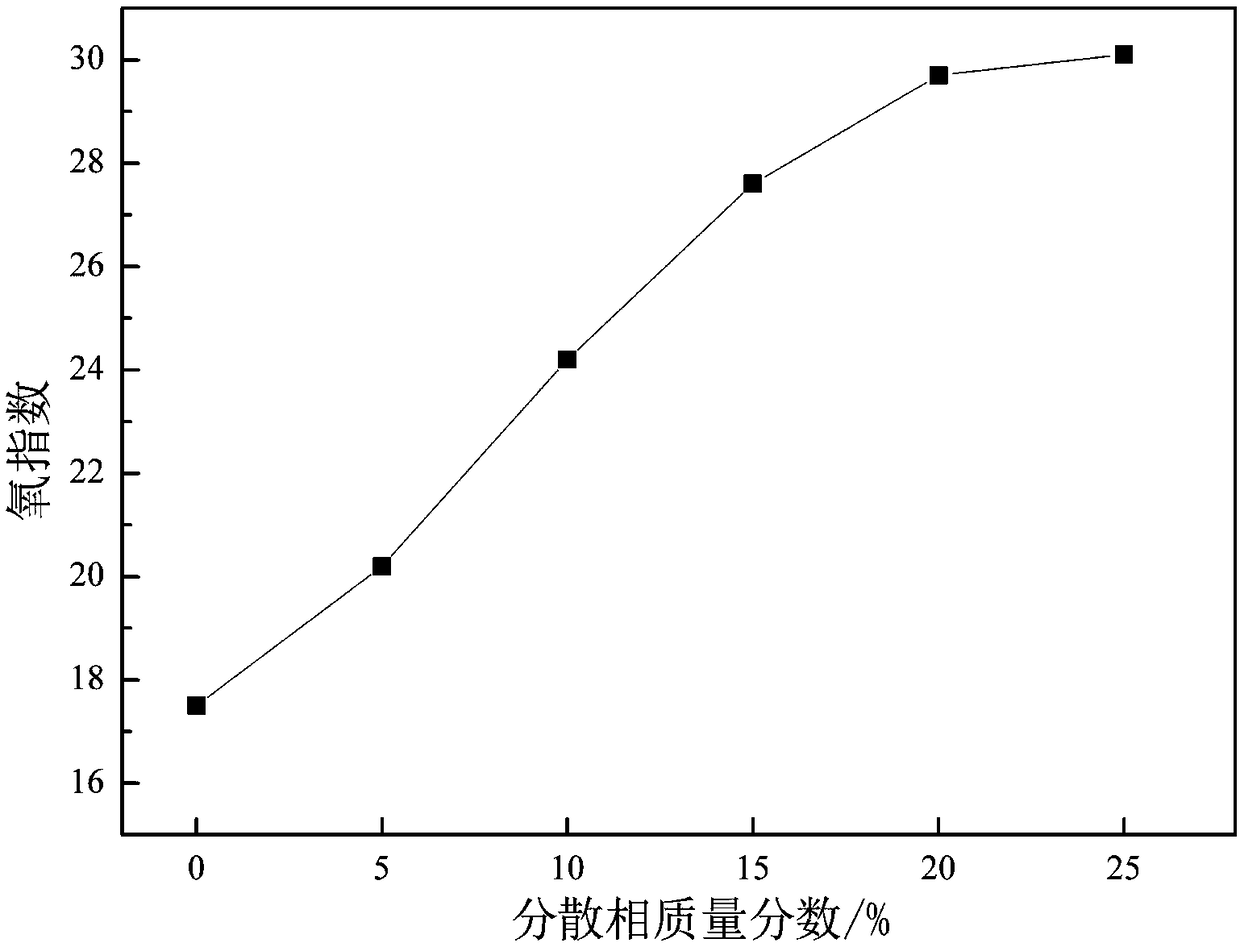

[0031] A method for preparing a high thermal conductivity flame-retardant polyethylene-based composite material, comprising the following steps:

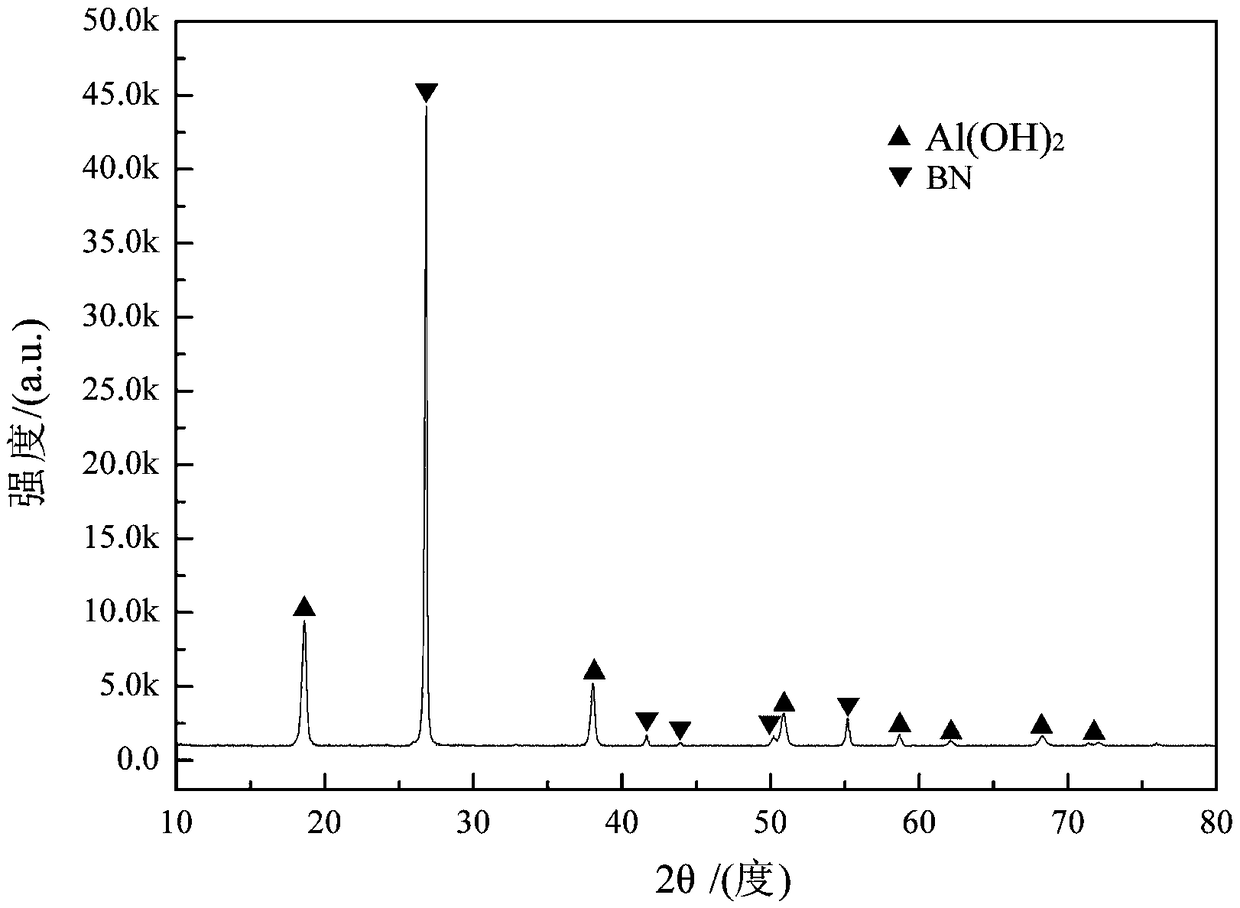

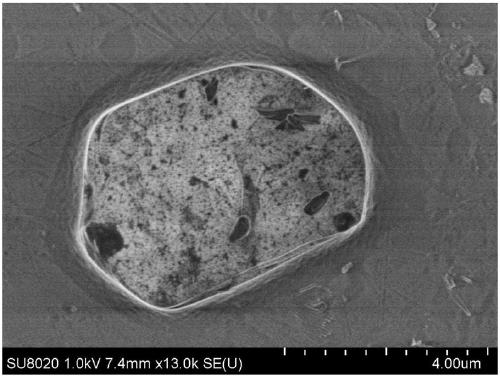

[0032] S1: Weigh the Al(OH) prepared by the sol-gel method according to the mass ratio of 1:1 3 Zero-dimensional powder and the purchased BN two-dimensional sheet, that is, hexagonal boron nitride two-dimensional sheet, the two powders are placed in a mixed liquid of absolute ethanol and ionic water with a volume ratio of 1:0.75, and an ultrasonic disperser is used to Disperse and strip the mixed powder with 600W ultrasonic for 24 hours, then stir the mixed liquid with a magnetic stirrer at room temperature at a speed of 600r / min for 1 hour, and finally use a centrifuge to centrifuge at a high speed of 10000r / min for 10min, and the obtained mixed powder The body is dried and ground for use;

[0033] S2: Put the mixed powder prepared in step S1 in a beaker, then measure an appropriate amount of absolute ethanol and place it in the b...

Embodiment 2

[0039] A method for preparing a high thermal conductivity flame-retardant polyethylene-based composite material, comprising the following steps:

[0040] S1: Weigh 1.2g of Al(OH) by sol-gel method 3 Zero-dimensional powder and 1.2g of purchased BN two-dimensional tablets, put the two powders in a mixed liquid of 30mL absolute ethanol and 20mL ionic water, and use an ultrasonic disperser to conduct ultrasonic treatment at 600W for 24 hours. Disperse and strip, then use a magnetic stirrer to stir the mixed liquid at room temperature at 600r / min for 1 hour, and finally use a centrifuge to centrifuge at a high speed of 10000r / min for 10 minutes, and dry and grind the obtained mixed powder for use;

[0041]S2: Put the mixed powder prepared in step S1 in a beaker, then measure 50mL of absolute ethanol and place it in the beaker, place the beaker on a magnetic stirrer and stir evenly for a period of time, then add 0.24g of amino functional silane (KH550 ), and then use a magnetic st...

Embodiment 3

[0047] A method for preparing a high thermal conductivity flame-retardant polyethylene-based composite material, comprising the following steps:

[0048] S1: Weigh the Al(OH) prepared by the sol-gel method according to the mass ratio of 1:0.2 3 Zero-dimensional powder and the purchased BN two-dimensional sheet, that is, hexagonal boron nitride two-dimensional sheet, the two powders are placed in a mixed liquid of absolute ethanol and ionic water with a volume ratio of 1:0.75, and an ultrasonic disperser is used to Disperse and strip the mixed powder with 550W ultrasound for 20 hours, then stir the mixed liquid with a magnetic stirrer at room temperature at a speed of 600r / min for 1h, and finally use a centrifuge to centrifuge at a high speed of 8000r / min for 10min, and mix the obtained mixed powder body drying and grinding for later use, wherein the mass ratio of the two-dimensional hexagonal boron nitride sheet to deionized water is 1:4.5;

[0049] S2: Put the mixed powder p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com