A kind of halogen-free flame-retardant high shading PC composite material and preparation method thereof

A composite material, high shading technology, applied in the field of polymer materials, can solve the problems of toughness and rigidity damage, low shading effect, and easily broken products, so as to reduce the influence of rigidity and toughness, simple preparation method, titanium dioxide small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

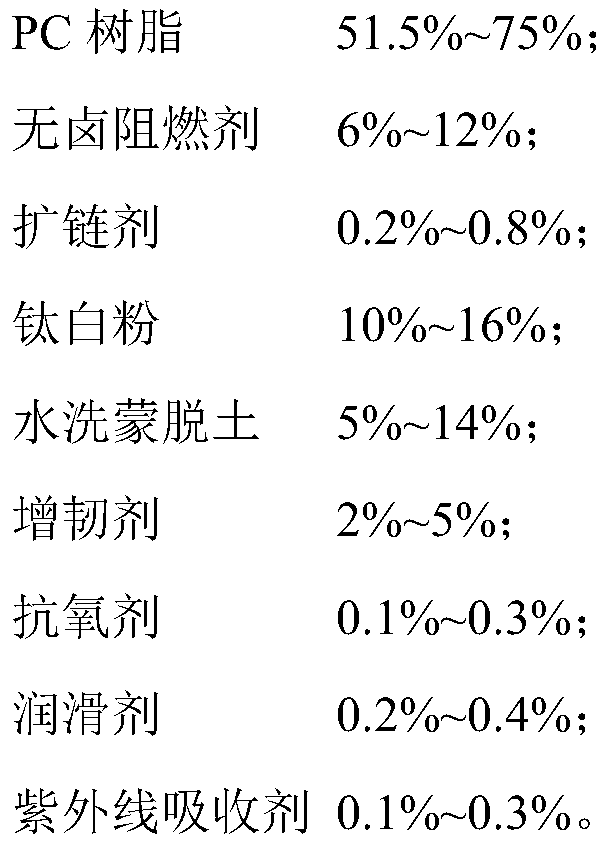

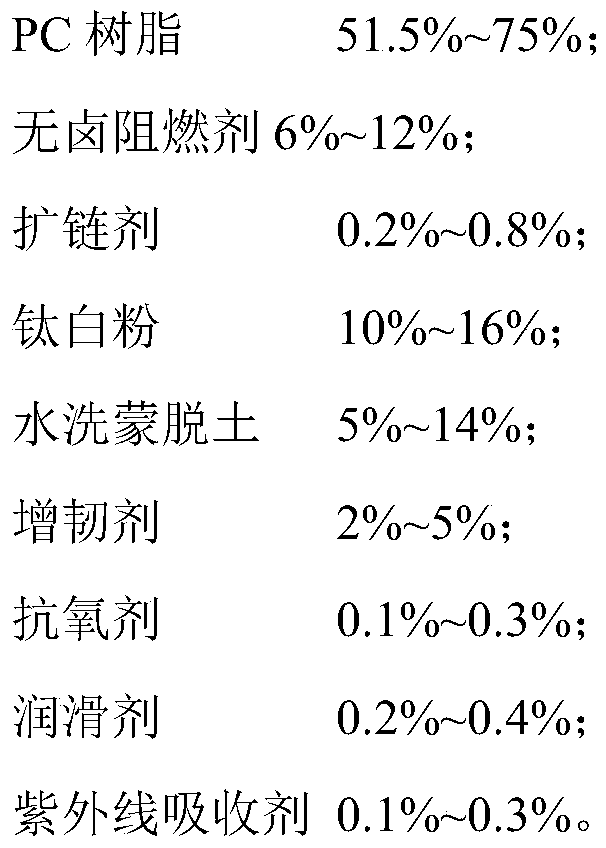

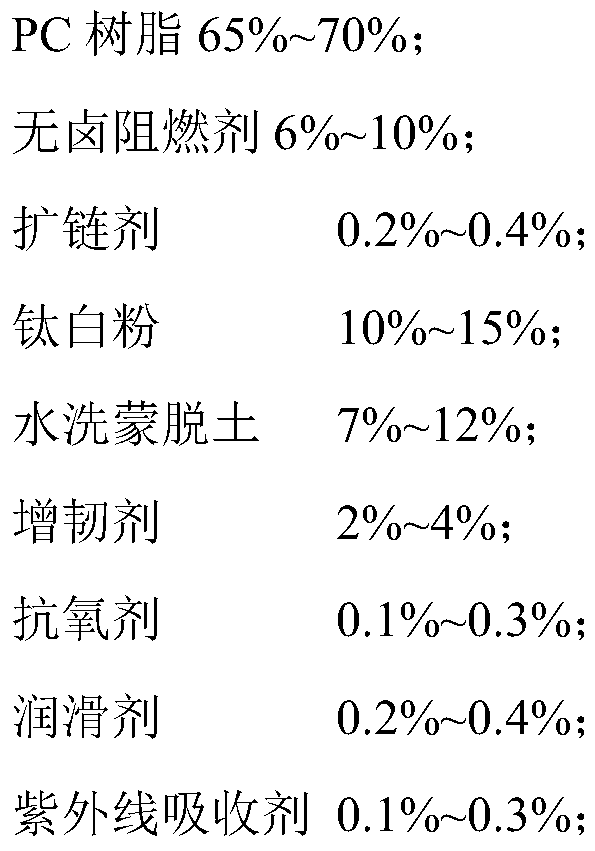

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of this halogen-free flame-retardant high light-shielding PC composite material comprises the following steps:

[0043] 1) drying the PC resin;

[0044] 2) Weigh the raw materials according to the aforementioned composition, and mix them uniformly;

[0045]3) Add the mixture obtained in step 2) into a twin-screw extruder, extrude, and granulate to obtain a halogen-free flame-retardant high-light-shielding PC composite material.

[0046] Preferably, in the step 1) of the preparation method, drying is performed at 110° C. to 120° C., the drying time is 3 h to 5 h, and the water content of the dried PC resin is lower than 0.02 wt%.

[0047] Preferably, in step 2) of the preparation method, mixing is performed in a high-speed mixer, the speed of the high-speed mixer is 400r / min-600r / min, and the mixing time is 5min-10min.

[0048] Preferably, in step 3) of the preparation method, the processing temperature in each zone of the twin-screw extruder is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com