A kind of silicon steel environment-friendly insulating coating for drive motor of new energy vehicle and preparation method thereof

A technology for new energy vehicles and drive motors, applied in anti-corrosion coatings, coatings, etc., to achieve excellent insulation performance, improved compactness, and improved welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

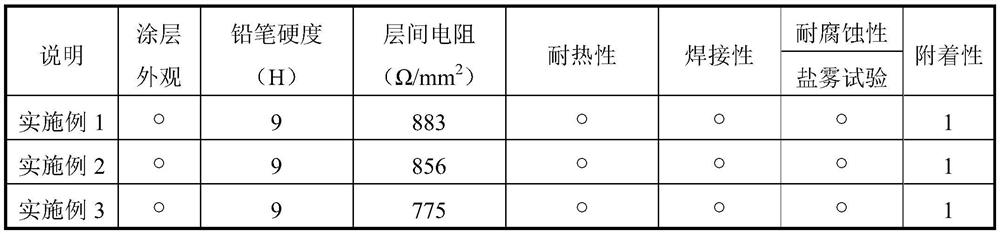

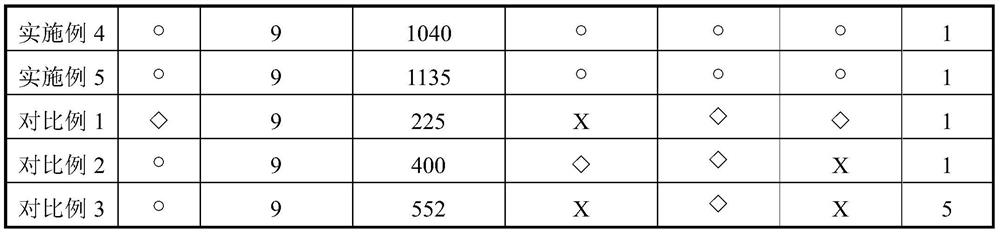

Examples

Embodiment 1

[0047] A new energy vehicle drive motor silicon steel environmental protection insulation coating, including the following raw materials by weight percentage:

[0048] Water-soluble acrylic resin 18%;

[0049] Sodium Allyloxy Hydroxypropyl Sulfonate 2%;

[0050] Al(H 2 PO 4 ) 3 15%;

[0051] Boric acid 6%;

[0052] Modified nano-SiO 2 14%;

[0053] Ethylene glycol 6%;

[0054] Auxiliary 2%;

[0055] The balance is deionized water, and the sum of each raw material is 100%; the auxiliary agent includes 0.3% dispersant, 0.5% wetting agent, 0.2% leveling agent, 0.5% film-forming auxiliary agent and 0.5% defoamer.

[0056] The modified nano-SiO 2 The preparation method is: take 30g of deionized water into the reactor, add 20g of nano-SiO 2 , add 50g of polytetrafluoroethylene emulsion under the high-speed dispersion condition of 800r / min, and stir for 30min under the condition of increasing the speed to 1200r / min, the prepared modified nano-SiO 2 spare;

[0057] The ...

Embodiment 2

[0061] A new energy vehicle drive motor silicon steel environmental protection insulation coating, including the following raw materials by weight percentage:

[0062] Water-soluble silicone acrylic resin 12%;

[0063] Sodium Allyloxy Hydroxypropyl Sulfonate 3%;

[0064] Mg(H 2 PO 4 ) 2 18%;

[0065] Lithium borate 5%;

[0066] Modified nano-SiO 2 12%;

[0067] Glycerol 5%;

[0068] Auxiliary 6%;

[0069] The balance is deionized water, and the sum of each raw material is 100%; the auxiliary agent includes 1.5% dispersant, 2.0% wetting agent, 1.0% leveling agent, 1.0% film-forming auxiliary agent and 0.5% defoamer.

[0070] The modified nano-SiO 2 The preparation method is: take 30g of deionized water into the reactor, add 20g of nano-SiO 2 , add 50g of polytetrafluoroethylene emulsion under the high-speed dispersion condition of 800r / min, and stir for 30min under the condition of increasing the speed to 1200r / min, the prepared modified nano-SiO 2 spare;

[0071...

Embodiment 3

[0075] A new energy vehicle drive motor silicon steel environmental protection insulation coating, including the following raw materials by weight percentage:

[0076] Water-soluble epoxy resin 8%;

[0077] Sodium Allyloxy Hydroxypropyl Sulfonate 2%;

[0078] Zn(H 2 PO 4 ) 2 20%;

[0079] Sodium borate 5%;

[0080] Modified nano-SiO 2 9%;

[0081] Butanthritol 4%;

[0082] Auxiliary 4%;

[0083] The balance is deionized water, and the sum of each raw material is 100%; the auxiliary agent includes 1.0% dispersant, 1.2% wetting agent, 0.8% leveling agent, 0.5% film-forming auxiliary agent and 0.5% defoamer.

[0084] The modified nano-SiO 2 The preparation method is: take 30g of deionized water into the reactor, add 20g of nano-SiO 2 , add 50g of polytetrafluoroethylene emulsion under the high-speed dispersion condition of 800r / min, and stir for 30min under the condition of increasing the speed to 1200r / min, the prepared modified nano-SiO 2 spare;

[0085] The prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com